The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size: <20mm

Output: 0.5-45 T/H

Product features: 1.High Efficiency 2.Long Lifecycle of Spare Parts 3.High Safety and Reliability 4.High Fineness and Flexible Adjustment 5.Environment-Friendly

The HGM Stone Mill Grinder, also known as the HGM series ultrafine powder grinder mill, is a highly advanced and efficient grinding machine designed to produce fine and superfine powders from a wide range of non-inflammable, non-explosive, and brittle materials with a Mohs hardness under 6.

This versatile equipment has gained significant popularity in various industrial sectors due to its ability to process over 100 different types of materials, including calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, kalium ore, pumice, and many others.

The HGM stone mill grinder can handle over 100 types of non-metallic minerals and materials with Mohs hardness ≤ 6 and moisture ≤ 6%. Common materials include:

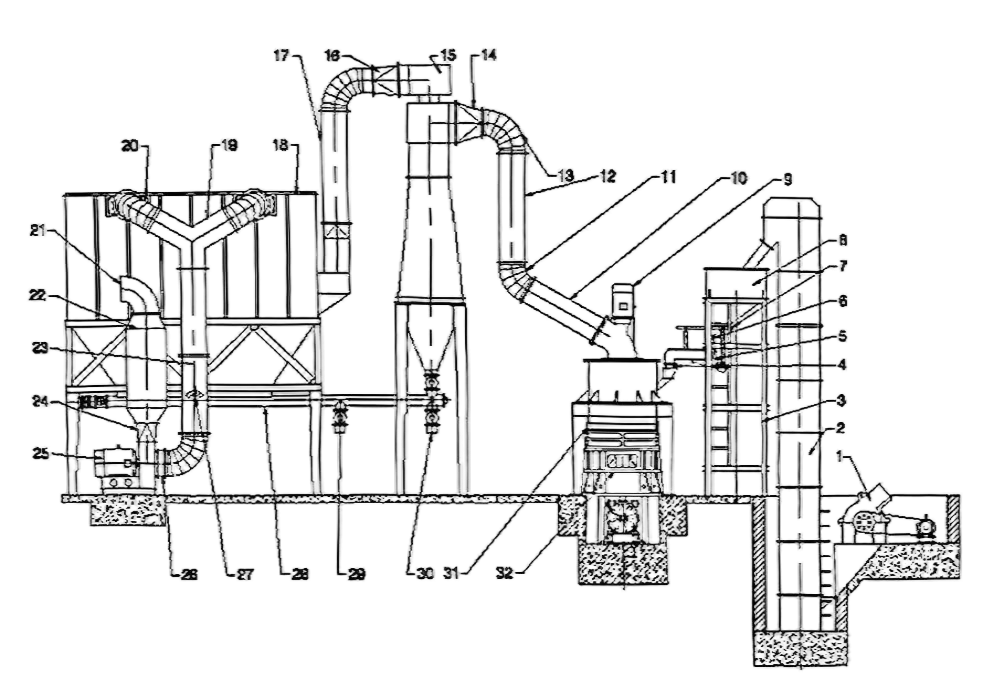

The HGM Stone Mill Grinder is a complex system comprising several key components that work together to ensure efficient and effective grinding operations. The main components include:

1.Hammer crusher

2.Elevator

3.Hopper stand

4.Feeding Inlet

5.Vibrating feeder

6.Flexible connection2

7.Feeder hanger

8.Hopper

9.Classifier

10.Straight pipe1

11.Bent pipe 60°

12.Straight pipe 2

13.Bent pipe 90°

14.Air inlet of powdier collector

15.Powdier collector

16.Air outlet of powder collector

17.Straight pipe3

18.Dust collector

19.Three-way pipe

20.Air outlet of dust collector

21.Air outlet of muffler

22.Muffler

23.Straight light 4

24.Air outlet of air blower

25.Air blower

26.Adjustable duct

27.Air volume controller

28.Conveyor

29.Discharging valve

30.Discharge outlet

31.Flexible connection1

32.Grinding mill main unit

33.Machine base

34.Coupling

35.Boaring assembly

36.Middle bocly

37.Ring

38.Flexibla connection

39.Classifier stand

40.Cylinder

41.Casting

42.Impeller

43.Upper distribution plate

44.Shaft pin

45.Roller

46.Turnplate

47.Lower distribution plate

48.Reducer

The working principle of the HGM Stone Mill Grinder is based on a combination of mechanical force and airflow dynamics.

The process begins with the large materials being crushed by a hammer crusher or jaw crusher and then transported to the storage hopper via a bucket elevator.

The materials are then evenly fed to the upper distribution plate of the turnplate by a vibrating feeder and a sloping feeding pipe.

When the grinding mill is in operation, the grinding rollers roll inside the grinding rings, applying significant pressure and grinding action to the materials.

The materials are driven to the edge of the turnplate by centrifugal force and fall into the grinding chambers, where they are repeatedly pressed, crushed, and ground by the rollers.

The high-pressure air blower continuously inhales air within the grinding mill, and the airflow carries the crushed materials to the classifier.

The classifier’s high-speed impeller screens the airflow: materials with unqualified particle sizes fall back into the mill for regrinding, while the qualified fine powders mixed with air move into the cyclone powder collector.

Most of the qualified powders exit through the discharge valve at the bottom, while a small portion of the fine powders moves to the dust cleaner, where they cling to the surface of the filter bags.

The fine powders are then dislodged by the sudden vibration of the filter bags, caused by the instant ejection of high-pressure gas controlled by a pulse valve.

Finally, the filtered clean air is emitted from the muffler’s air outlet.

The HGM Stone Mill Grinder finds extensive applications across various industries due to its ability to produce fine and superfine powders from a wide range of materials. Some of the key application areas include:

The HGM Stone Mill Grinder is available in various models to meet different production capacities and material requirements. Some of the key technical data for different models are as follows:

| Model | HGM80 | HGM90L | HGM100L-Ⅱ HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number(layer) | 3 | 3-4 | 4 | 4 | 4 |

| Roller Number(piece) | 18-21 | 24-29 | 28-36 | 30-40 | 30-44 |

| Main Shaft Speed(r.p.m) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size(mm) | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

| Finished Size(μm/mesh) | 74-5 (200-2500) | 74-5 (200-2500) | 74-5 (200-2500) | 100-6 (150-2000) | 100-9 (150-1500) |

| Capacity(t/h) | 0.5-5.5 | 0.8-6.5 | 1.2-10 1.2-11 | 2.5-20 | 5-45 |

| Overall Dimension(L*W*H,m) | 15.1*4.2*7.3 | 18.4*3.9*7.8 | 22.7*3.6*8.5 | 27.3*4.2*9.9 | 31.7*7.7*12.6 |

| Note: The capacity is based on the domestic CaCO₃ powder factories’ feedback. | |||||

The HGM Stone Mill Grinder is a highly efficient and versatile grinding machine that offers numerous advantages over traditional grinding mills.

Its ability to produce fine and superfine powders from a wide range of materials, combined with its high efficiency, long-lasting spare parts, and environmentally friendly design, makes it an ideal choice for various industrial applications.

Whether used in the metallurgy, building materials, chemical, or mining industries, the HGM grinder ensures high productivity, reliability, and compliance with environmental standards.

|

Model

|

HGM80

|

HGM90L

|

HGM100L-Ⅱ

HGM100P |

HGM125L

|

HGM1680L

|

|

Ring Diameter(mm)

|

800

|

900

|

1000

|

1250

|

1680

|

|

Ring Number(layer)

|

3

|

3-4

|

4

|

4

|

4

|

|

Roller Number(piece)

|

18-21

|

24-29

|

28-36

|

30-40

|

30-44

|

|

Main Shaft Speed(r.p.m)

|

230-240

|

200-220

|

180-200

|

135-155

|

120-130

|

|

Input Size(mm)

|

≤20

|

≤20

|

≤20

|

≤20

|

≤20

|

|

Finished Size(μm/mesh)

|

74-5

(200-2500) |

74-5

(200-2500) |

74-5

(200-2500) |

100-6

(150-2000) |

100-9

(150-1500) |

|

Capacity(t/h)

|

0.5-5.5

|

0.8-6.5

|

1.2-10

1.2-11 |

2.5-20

|

5-45

|

|

Overall Dimension(L*W*H,m)

|

15.1*4.2*7.3

|

18.4*3.9*7.8

|

22.7*3.6*8.5

|

27.3*4.2*9.9

|

31.7*7.7*12.6

|

|

Note: The capacity is based on the domestic CaCO₃ powder factories’ feedback.

|

|||||

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.