Focus on the field of micro powder grinding

Focus on the field of micro powder grinding

Integrated solution provider

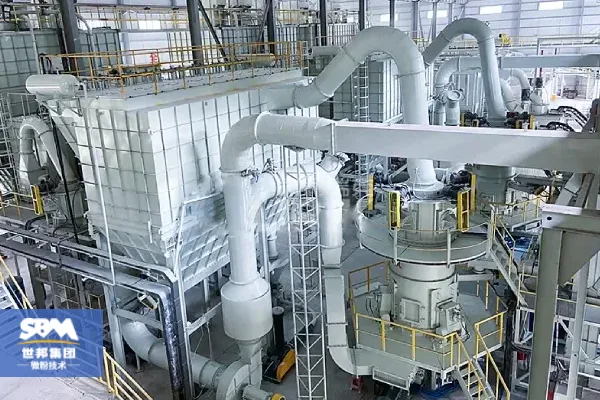

Material: Limestone

Fineness: 1500mesh

Capacity: 12 t/h

see More >>Material: Iron Oxide

Fineness: 1250mesh

Capacity: 1.2 t/h

see More >>

Regularly report on mineral powder industry

HGM Ultrafine Grinding Mill: Advanced Solution for Calcium Carbonate and Beyond In today’s industrial world, the demand for ultrafine powders continues to grow rapidly. From coatings, plastics, and paper to construction, food additives, and pharmaceuticals, industries require powders of higher fineness, improved uniformity, and greater consistency to meet evolving application needs. One of the most […]

In the Iron Oxide Grinding Production Line, HGM80 ultrafine mill is used to process 1250 mesh iron oxide powder, with an hourly output of 1.2 tons.

Rhyolite is a silica-rich volcanic rock widely used in construction materials and ceramics.Processing involves crushing → grinding → classification to achieve different applications. Rhyolite is a type of volcanic igneous rock that forms from high-silica (acidic) lava. It is chemically similar to granite, but because it cools quickly on or near the Earth’s surface, its […]

The industrial pursuit of high-performance, sustainable materials has positioned Recovered Carbon Black (RCB), derived from the pyrolysis of End-of-Life Tires (ELT), as a critical feedstock. Transitioning this carbonaceous residue into a high-grade industrial filler—often requiring fineness within the 5 to 45 μm range (equivalent to 2500 to 200 mesh )—demands grinding technology defined by unprecedented […]

Using the HGM Ultrafine Grinding Machine to process Chromium Oxide Green (Cr₂O₃) is an efficient way to achieve high fineness, uniform particle size distribution, and stable pigment quality, especially for paint, coating, and ceramic applications. About Chromium Oxide Green Chromium Oxide Green (Cr₂O₃) is an inorganic green pigment widely used in paints, coatings, plastics, ceramics, […]

Mineral Mill for Raw Olivine Sand: We offer advanced grinding solutions with HGM Ultrafine Mill and CLRM Raymond Mill for efficient olivine powder processing. To transform raw olivine sand into industrial-grade fine powders, advanced mineral mill solutions are essential. As a leading Chinese manufacturer of grinding mills, we offer cutting-edge technologies to meet this demand. […]

In the Nigeria project, the HGM ultra-fine roller mill was installed and commissioned. The machine can produce 400-mesh barite powder with an output of about 6 tons per hour. In the rapidly evolving world of industrial mineral processing, the demand for high-efficiency, low-energy-consuming grinding equipment has never been greater. This is especially true in countries […]

HGM Ultrafine Grinding Mill for Bentonite Drilling Powder Bentonite, a clay mineral dominated by montmorillonite, plays an indispensable role in the global drilling industry. Whether in oil and gas exploration, geothermal wells, or water well drilling, bentonite is the backbone material of drilling mud formulations. Its swelling capacity, colloidal properties, and ability to control fluid […]

HGM Ultrafine Grinding Mill: Advanced Solution for Calcium Carbonate and Beyond In today’s industrial world, the demand for ultrafine powders continues to grow rapidly. From coatings, plastics, and paper to construction, food additives, and pharmaceuticals, industries require powders of higher fineness, improved uniformity, and greater consistency to meet evolving application needs. One of the most […]

Igneous Rock Crushing And Grinding Equipment typically includes jaw crushers for primary reduction and cone crushers or impact crushers for secondary crushing, followed by ball mills or vertical roller mills for fine grinding, as these durable machines must process extremely hard volcanic-formed rocks like basalt and granite. What is igneous rock? Igneous rocks are formed […]