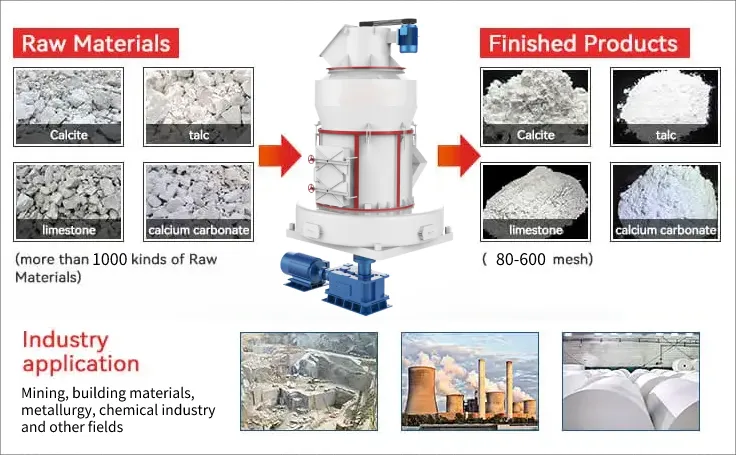

Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

Discharge fineness: 80-500 mesh

Feed size: <35 mm

Output: 1-35 t/h

Materials:

Product features: The CLRM series enhanced roller grinding mill has the characteristics of stable operation, reliable operation, fineness of the finished product is widely adjusted and long service life.

Andalusite is an island-shaped anhydrous silicate mineral, usually gray, yellow, brown, rose, flesh red or dark green (variety containing manganese), and colorless is rare. Andalusite has good fire resistance, resistance to sudden cooling and sudden heat, high mechanical strength, strong thermal shock resistance, strong slag resistance, high load conversion point, and extremely high chemical stability (even insoluble in hydrofluoric acid) and extremely strong chemical resistance. The Mohs hardness of andalusite is 6.5~7.5, and the specific gravity is 3.15~3.16.

To date, the largest andalusite deposits occur in South Africa. Andalusite reserves on earth are concentrated in South Africa, France and China. Spain, Portugal, Russia, Ghana, South Korea, California and North Carolina in the United States also have certain reserves.

1. Making indeterminate refractory materials: adding a certain amount of andalusite to the ingredients, using the characteristics of stable expansion, can eliminate the shrinkage of amorphous materials, control and reduce the shrinkage of refractory products under long-term high temperature, and prolong the service life of materials Up to five years.

2. Refractory bricks: the pillars are calcined and made into profiles, which can be used in key parts such as hot blast stoves, hot blast towers, reheating, etc., and can also be used in various auxiliary pouring and operating equipment, and can also be used to make kiln facilities, high temperature aluminosilicate Salt insulators, foundry fabrics. Can reduce fuel consumption and increase stability.

3. It is the raw material for the production of silicon-aluminum alloy, alumina and aluminum metal: due to the high content of andalusite Al2O3 and the low content of oxide impurities such as iron, titanium and calcium, it can be used for the production of silicon-aluminum alloy containing 60% aluminum. Aluminum oxide can simplify the production process and improve production efficiency.

Andalusite can be processed into 80-500 mesh andalusite powder by CLRM Raymond mill, which can be used as industrial raw material for refractory materials and ceramic industry.

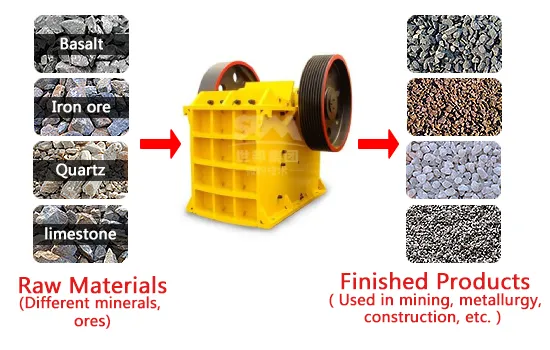

The first stage of the andalusite pulverizer: The crushed large ore is transported to the raw material warehouse by a special vehicle, and then the material is manually sent to the jaw crusher by a forklift for crushing, and the crushed material is smaller than the feed size of the pulverizer.

The second stage of the andalusite mill: the ore crushed by the crusher is lifted to the storage hopper by the elevator, and the material is discharged from the storage hopper, and then fed to the main machine evenly by the feeder.

The third stage of the andalusite mill: the qualified products in the grinding process are screened by the screening system and enter the collector through the pipeline. After collection, they are discharged through the discharge valve and become finished products. The unqualified products fall into the main machine for re-grinding.

The fourth stage of andalusite pulverizer: the airflow after the purification of the finished product flows into the blower through the residual air pipe above the dust collector. Down flow, indoor sanitary conditions are better.

In the production and processing of andalusite, grinding is one of the more important processes. The andalusite milling production line can process materials to the particle size required by the user, thereby improving production efficiency and increasing output, so what are the andalusite milling production line equipment?

Jaw crusher is the necessary equipment for coarse crushing of andalusite. The particle size of the crushed material can be adjusted within the range of 10mm-400mm. The advantages of the equipment in operation are:

1. Reasonable crushing speed and deep crushing cavity improve the crushing efficiency and increase the output of the equipment.

2. There is a dust-proof board inside the machine body, which can effectively prevent dust from spilling during production and improve the working environment of the equipment.

3. The gasket adjustment device is replaced by the wedge adjustment device, which makes the adjustment process of the equipment more convenient and faster.

In the grinding process of andalusite, Raymond mill is the main high-fine grinding processing equipment. It not only has high grinding efficiency, but also has the following characteristics.

1. Adopting vertical structure design, the equipment is small in size and light in weight, which is convenient for operation and movement during operation.

2. The user can centrally control the equipment, which not only reduces the cost investment in human resources, but also facilitates the use and maintenance of the equipment.

3. There is no direct contact between the grinding roller and the grinding disc during the operation of the equipment, which reduces wear and prolongs the life of the equipment.

4. It is suitable for grinding limestone, titanium dioxide, quartz stone, bauxite, andalusite and other non-metallic minerals with Mohs hardness below 7 and humidity within 6%. The finished product fineness is 80-500 mesh can be adjusted arbitrarily.

The electromagnetic vibrating feeder is an automatic equipment for flow operation. In the andalusite grinding production line, the material andalusite can be sent from the storage bin to the receiving device in a regular and quantitative manner. Its characteristics in operation have:

● Simple structure and convenient operation.

● No need for lubrication, low power consumption, and low cost for users.

The bucket elevator is to lift the low-level materials to a certain height, so as to meet the needs of users in production. The advantages of its operation are as follows:

● The lifting height of the equipment is high, and the transportation volume is large.

● The lifting range is wide, not only can lift powdery materials, but also has a good lifting effect on abrasive materials.

● The service life is long, and there is little extrusion and collision between materials during lifting, which reduces wear and makes the equipment more durable.

1. The CLRM andalusite milling production line has reasonable configuration, high degree of automation, and small footprint, which effectively reduces the customer’s infrastructure funds.

2. The investment is small, and the return is fast, which reduces the investment cost of the majority of customers, maximizes the benefits of the andalusite factory, and meets the requirements of all customers.

3. The working environment reduces pollution and is equipped with dust removal equipment, so the pollution in the working process is very small and the working environment is improved.

4. The sieving efficiency of the finished product is high, sometimes up to 99%. This is not available in other milling equipment, and it can meet the customer’s particle size requirements for finished andalusite powder.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.