The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

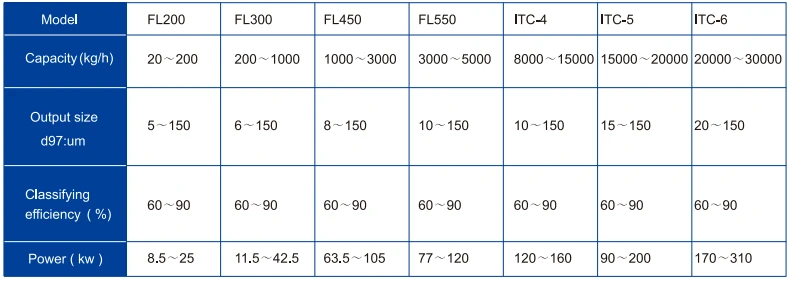

Output size: 5-150 um

Classifying efficiency: 60% – 90%

Product features: Suitable for dry fine powder classifying, powders of ball shape, flake shape and needle shape, also powders with different densities.

Air classifier is mainly used for 3-25um, D50 through sieve powder screening. Air classifier works with cyclone separator, dust collector and suction fan to form a complete classifying system.

Material would go from the bottom part of air classifier up to the classifying chamber by the air flow from suction fan. The high—speed rotation of the classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder.

Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while the mixture of coarse powder and fine powder would lose its speed and fall down along the house wall to the secondary air inlet.

The secondary air flow would disperse it further and separate coarse and fine powder. Fine powder would go up to the classifying chamber for further classifying, while coarse powder would fall down and go out from the bottom outlet.

Suitable for dry fine powder classifying, powders of ball shape, flake shape and needle shape, also powders with different densities.

① Product size from classifier can vary from d97: 2 micron to 150 micron. The product size is adjustable, which makes the change of product size easy and simple.

② Classifying efficiency (extraction rate) can be between 60% and 90%. Material with good flow—ability would have high classifying efficiency, otherwise, the classifying efficiency would be low.

③ Vertical type of classifier wheel would have low rotation speed, low wear and low motor power.

④ It can be connected with ball mill, vibration mill or Raymond mill to form a close—loop recycling system.

⑤ Negative—pressure system. Dust emission would be less than 40 mg/m3. Our machines have noise isolation device, which makes noise not higher than 75dB(A).

⑥ The classifier adopts alumina lining protection. The impeller is made of macromolecule wearable material. So it is more suitable for hard materials, or materials, have high demand on iron content.

⑦ The classifier adopts frequency to control the rotating speed of the impeller. Cooperating with classifying airflow, fine particles will be classified.

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.