The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 0.5-45 T/H

Product features: Small footprint, high efficiency, low energy consumption, simple operation, convenient maintenance and long service life, and flexible adjustment of finished product fineness

HGM series albite ultrafine grinding mill is a high-efficiency, low-energy consumption industrial ore grinding equipment. There are 5 models of the equipment, which can process 100+ kinds of non-metallic ores, as well as shells, bamboo and other materials. The fineness of the finished product can be freely adjusted between 150-3000 mesh, and can reach D97≤5um at one time.

Albite is a raw material for making glass and ceramics. The appearance of albite is generally white and off-white, with a Mohs hardness of 6 – 6.5, a density of 2.61 to 2.64 g/cm3, and a melting point of about 1100 °C.

HGM ultrafine grinding mill can grind albite into ultrafine powder, which is mainly used as glass solvent, ceramic body ingredients, ceramic glaze, enamel raw materials, etc. It is widely used in ceramics, glass, enamel, soap, ceramic tiles, floor tiles, abrasives and other industries.

The standard configuration of HGM ultrafine grinding mill includes main engine, powder separator, pulse dust collector, powder collector, high pressure fan, motor, pipeline, muffler, hammer breaker, elevator, feeder and electric control cabinet.

HGM ultrafine grinding mill

Adjustable fineness: 150-3000 mesh

Output: 1-20 t/h

Machinable materials: It is suitable for the processing of non-flammable and explosive brittle materials with medium and low hardness, and can grind calcium carbonate, kaolin, bentonite, talc, mica, barite, gypsum, graphite and many other materials.

Application: It is used in many industries such as paints, papermaking, pigments, rubber, plastics, fillers, cosmetics, chemicals and so on.

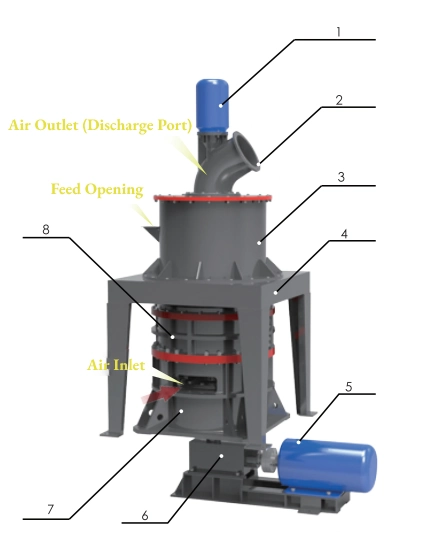

1. electric motor of classifier

2. upper part of classifier

3. lower part of classifier

4. support

5. electric motor of main engine

6. main engine speed reducer

7. bottom body (engine base)

8. middle body

① High efficiency and low energy consumption, the output is more than double that of jet mill, and the energy consumption is 30% lower.

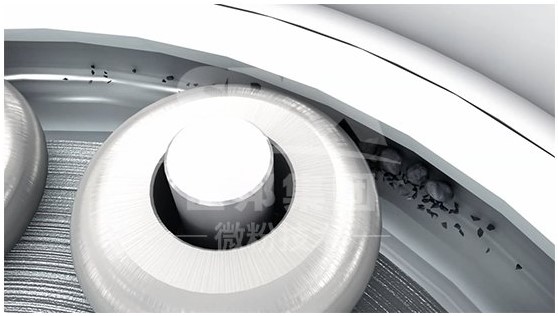

② The ring roller is forged with special materials, and the durability is increased several times.

③ The mold cavity has no bearing screws and is balanced to ensure stable operation without vibration.

④ High-efficiency vertical turbine powder separator, high efficiency, accurate cutting particle size, no coarse powder phenomenon.

⑤ Frequency conversion control, convenient and fast adjustment control, one-time finished product can reach D97≤5um.

⑥ Automatic feedback, fast and stable conversion of finished products; intelligent control, saving labor costs.

⑦ Double dust collector with high efficiency dust collector and pulse dust collector, with good effect and good dust collection.

⑧ The optimized design of the soundproof room and muffler can effectively control the transmission of equipment noise.

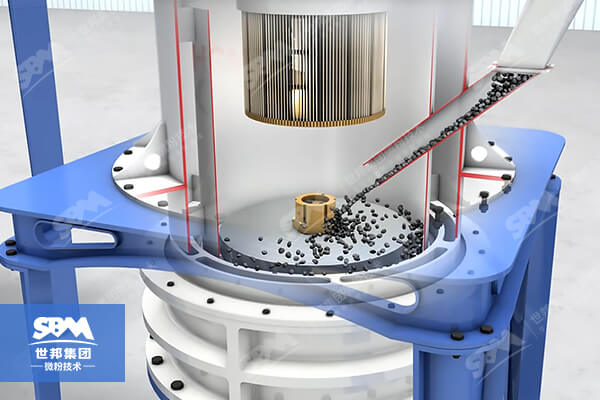

The main engine motor inputs the power to the main shaft through the main engine reducer, and then drives the turntables of each layer to rotate. The turntable drives the three-layer ring roller (some models are four-layer ring roller) to roll in the grinding ring raceway through the pin.

After the large material is broken into small particles by the hammer crusher, it is sent to the storage bin by the elevator, and the electromagnetic vibrating feeder evenly sends the material to the middle of the upper turntable through the feeding port.

Under the action of centrifugal force, the material is scattered to the periphery of the garden, and falls into the raceway of the grinding ring to be punched, rolled, ground and crushed by the ring roller. After being crushed by the first layer, the material falls into the second layer and the third layer for further crushing.

The high-pressure centrifugal fan sucks the external air into the machine cavity, and sends the three-layer pulverized material into the classifier. The rotating turbine in the concentrator makes the coarse-grained materials that do not meet the requirements fall back for regrinding. The fine powder enters the cyclone powder collector with the airflow and is discharged through the discharge valve at the lower part, which is the finished product. The airflow with a small amount of fine dust is purified by the pulse dust collector and discharged through the fan and muffler.

| Parameters of HGM ultrafine grinding mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Model: HGM

Accepted delivery terms: FOB, CFR, CIF, EXW, CPT, DDU, express

Acceptable payment currency: USD

Acceptable payment methods: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.