The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Material: Limestone

Fineness: 1500mesh

Capacity: 12 t/h

Purpose: From coatings, plastics, and paper to construction, food additives, and pharmaceuticals, industries require powders of higher fineness, improved uniformity, and greater consistency to meet evolving application needs.

In today’s industrial world, the demand for ultrafine powders continues to grow rapidly. From coatings, plastics, and paper to construction, food additives, and pharmaceuticals, industries require powders of higher fineness, improved uniformity, and greater consistency to meet evolving application needs. One of the most critical raw materials in this regard is calcium carbonate (CaCO₃).

Calcium carbonate is widely used as a filler and functional additive in multiple industries, and its processing has become a benchmark for evaluating the performance of grinding equipment. Meeting the requirements of fineness, throughput, and energy efficiency is not only an engineering challenge but also a decisive factor for industrial competitiveness.

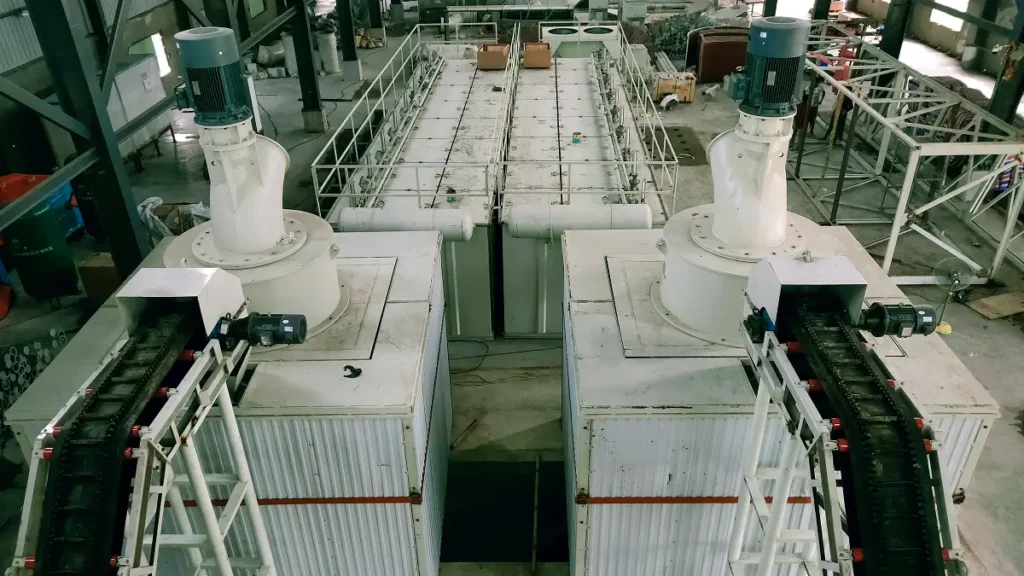

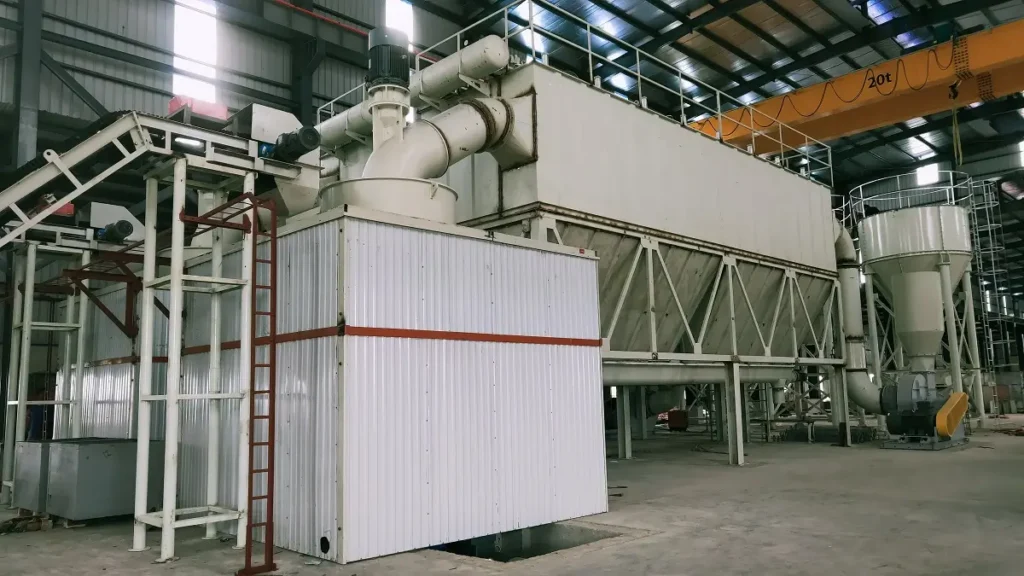

Recently, two sets of HGM125 ultrafine grinding mills were successfully put into operation in a large-scale calcium carbonate project in Bangladesh, providing an excellent example of how the HGM ultrafine mill is transforming powder processing industries worldwide.

In Bangladesh, calcium carbonate is in high demand for use in the construction, plastics, paints, and coatings industries. To meet the market requirements for high-quality ultrafine CaCO₃ powders, a local company invested in a new production line.

To ensure efficiency, reliability, and cost-effectiveness, the customer selected two sets of HGM125 ultrafine mills. The equipment was installed and commissioned successfully, now serving as the core grinding technology for the project.

This project demonstrates how HGM Ultrafine Mill can deliver a sustainable and profitable powder processing solution in rapidly developing industrial markets.

The HGM Ultrafine Ring Roller Mill is a high-efficiency industrial grinding machine designed for producing ultrafine powders. Unlike traditional ball mills or Raymond mills, which are limited in their ability to achieve extreme fineness, the HGM series is capable of producing powders ranging from 150 mesh to 3000 mesh (74 μm down to 5 μm).

The machine adopts a ring and roller grinding system combined with a multi-layered design, allowing materials to be ground multiple times in a single pass. This ensures not only finer output sizes but also greater uniformity in particle distribution.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.