The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000mesh

Feed size: <15mm

Output: 1-20 T/H

Product features: It has outstanding characteristics such as high grinding efficiency, convenient maintenance, low operating cost, high reliability, stable product quality, excellent finished product quality, and low comprehensive investment cost.

Calcium carbonate ultrafine vertical mill, mainly used for the production of calcium carbonate powder. Calcium carbonate powder can be widely used in cables, papermaking, toothpaste, cosmetics, glass, medicine, paint, ink and many other fields, and has high market application value.

CLUM series calcium carbonate ultrafine vertical mill, a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging, focusing on the large-scale production field of non-metallic mineral ultrafine powder processing. It has outstanding characteristics such as high grinding efficiency, convenient maintenance, low operating cost, high reliability, stable product quality, excellent finished product quality, and low comprehensive investment cost.

CLUM series ultrafine vertical mill

Adjustable fineness: 150-3000 mesh

Application: It can be widely used in chemical, metallurgy, non-metallic mining and other industries. Especially in the field of ultrafine grinding of white non-metallic minerals, it has outstanding performance. It can provide high-quality fillers and additives for papermaking, coatings, plastics, rubber, PVC, ink and other industries.

Processable materials: It can be used for large-scale ultra-fine dry powder processing of non-metallic minerals such as calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, wollastonite, gypsum, feldspar, pyrophyllite, etc.

Energy efficient

In the case of the same fineness of the finished product and the same motor power, the output is more than twice that of jet mill, stirring mill, and ball mill.

High safety and reliability

Because there are no rolling bearings and no screws in the grinding cavity, there is no problem that the bearings and their seals are easily damaged, and there is no problem that the screws are easy to loosen and damage the machine.

Easy to maintain

The grinding roller can be turned out of the machine with a hydraulic device, the replacement of the roller sleeve liner and the grinding machine have a large maintenance space, and the maintenance operation is very convenient.

Long service life of

wearing parts

The grinding roller and grinding ring are forged with special materials, which greatly improves the utilization. Generally, it can reach more than one year, and the service life can reach 2-5 years when processing calcium carbonate and calcite.

Environmental protection

(1) The whole system of CLUM ultrafine vertical mill has low vibration and low noise.

(2) The system is sealed as a whole, runs under full negative pressure, no dust spills, and basically a dust-free workshop can be realized.

(3) The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

Stable product quality

(1) The material stays in the mill for a short time, it is easy to detect the particle size distribution and composition of the product, and the product quality is stable.

(2) The product has uniform particle shape, narrow particle size distribution, good fluidity, and strong product adaptability.

Calcium Carbonate Ultrafine Vertical Mill is mainly composed of electric motor, reducer, grinding wheel device, grinding disc device, pressurizing device, powder separator, feeding device, oil station, main engine, electronic control system and other parts.

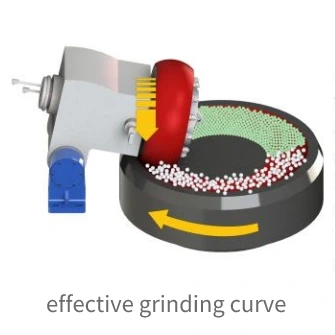

Grinding wheel device: the main part of the material to be rolled, without power output, and passively running due to the friction force in contact with the material.

Grinding disc device: the grinding area of the material, connected to the reducer, rotates by itself.

Pressure device: control the gap between the grinding wheel and the grinding disc to ensure the pressure of the grinding wheel during the grinding process.

Powder separator: The multi-head powder separator structure uses the principle of rotating centrifugal force to realize the fine powder screening and filtration in continuous production. It is a highly efficient and energy-saving powder separator.

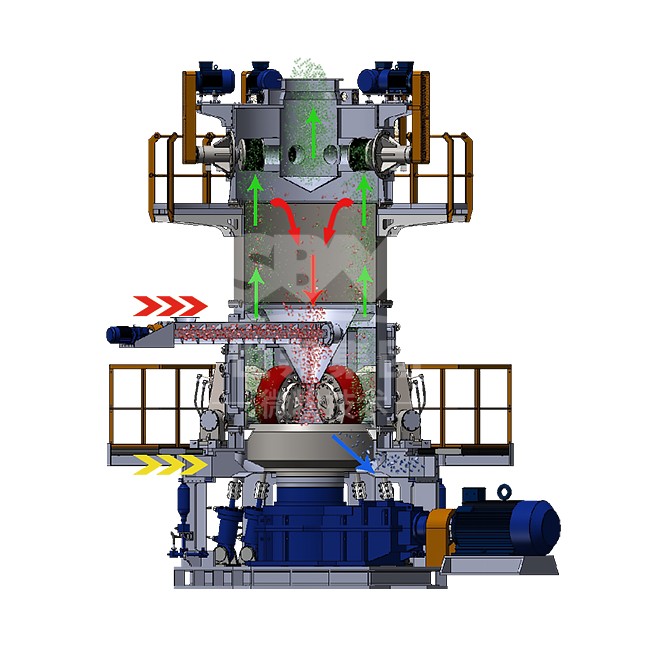

The main engine motor drives the milling disc to rotate through the reducer, while the air flow produced by the high-pressure fan enters the main engine from the tuyere.

The material is fed into the main machine of the vertical roller mill by the feeding screw and falls into the center of the grinding pan. Under the action of the centrifuge, the material is scattered from the center of the grinding pan to the surroundings.

When passing through the roller table area on the grinding pan, the bulk material is directly crushed by the pressure of the roller. After the small particles are compressed, they can be further pulverized until they become powder.

The powdered material continues to move to the edge of the grinding pan until it is taken away by the strong airflow from the air inlet.

When the materials in the airflow pass through the upper powder separator, under the action of the centrifugal force generated by the high-speed rotating impeller, the coarse particles fall into the grinding disc for grinding again, and the qualified powder passes through the powder separator system with the airflow and is collected by the dust collector, which is the finished product.

Ultrafine vertical roller mill stone powder production line

CLUM vertical roller mill working principle

Superfine grinding site of calcium carbonate in Hechi, Guangxi, China.

The production line of superfine calcium carbonate with an annual output of 300,000 tons. The total investment of the project is 140 million and it covers an area of 40,000 square meters.

Processing material: calcium carbonate

Product fineness: 200-3000 mesh

Material output: 300,000 tons/year

Equipment configuration:

CLUM1425 ultrafine vertical mill, HGM125 ultrafine grinding mill, FJJ secondary powder selection system, finished material conveying system, automatic packaging and palletizing system, centralized control system

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 6 |

| Power of classifier (Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power (Kw) | 180-200 | 250-280 | 325-410 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output (t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output (t/h) | 3-4 | / | / |

Material: base on calcite

Particle size distribution: measured by microlayer diffraction particle size analyzer in British Malvern 3000 instruments

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

Strict implementation of quality standards, quality assurance of ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Model: CLUM

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.