The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

25/09/2025 admin

In the Nigeria project, the HGM ultra-fine roller mill was installed and commissioned. The machine can produce 400-mesh barite powder with an output of about 6 tons per hour.

In the rapidly evolving world of industrial mineral processing, the demand for high-efficiency, low-energy-consuming grinding equipment has never been greater. This is especially true in countries like Nigeria, where the mining sector plays a pivotal role in economic diversification and industrial growth. Recently, a significant milestone was achieved in Nigeria with the successful installation and commissioning of the HGM Ultra-fine Roller Mill, a state-of-the-art grinding machine designed for producing ultra-fine mineral powders.

This project not only underscores the growing adoption of advanced grinding technologies in Africa but also highlights the HGM mill’s capability to meet stringent production requirements. With a designed output of 400 mesh barite powder at 6 tons per hour, the machine has proven its worth through stable operation, energy efficiency, and consistent product quality. This article delves deep into the features, advantages, and industrial significance of the HGM Ultra-fine Roller Mill, with a special focus on its recent success in Nigeria.

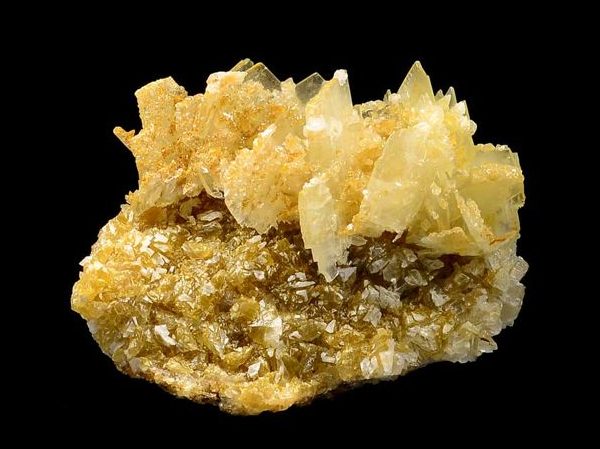

The HGM Ultra-fine Roller Mill is a cutting-edge grinding mill developed for the ultra-fine processing of non-metallic minerals such as barite, limestone, calcite, marble, talc, gypsum, dolomite, and kaolin. It is widely recognized for its ability to produce powders with fineness ranging from 325 mesh to 2500 mesh (or 45 to 5 microns), making it ideal for industries that require high-precision particle size control.

Manufactured with advanced technologies and high-quality materials, the HGM mill integrates grinding, classifying, and conveying into a single system. It is designed to operate continuously and efficiently, even under demanding industrial conditions.

One of the standout features of the HGM mill is its ability to produce ultra-fine powders with exceptional consistency. The adjustable fineness control allows operators to tailor the output to specific industrial needs. In the Nigerian project, the mill was configured to produce 400 mesh barite powder, a specification commonly required in the oil and gas drilling industry.

Energy consumption is a critical factor in mineral processing operations. The HGM mill is engineered to maximize grinding efficiency while minimizing power usage. Compared to traditional ball mills or Raymond mills, the HGM ultra-fine mill consumes significantly less energy per ton of output, making it a more sustainable and cost-effective solution.

The robust design of the HGM mill ensures long-term operational stability. Its wear-resistant components and intelligent control system reduce downtime and maintenance costs. In the Nigerian installation, the mill demonstrated stable and continuous operation, meeting the client’s production targets without interruption.

Unlike conventional mills, the HGM series mill features an integrated dynamic classifier that ensures precise control over particle size distribution. This is crucial for applications like barite powder used in drilling fluids, where particle size affects viscosity, density, and overall performance.

With increasing emphasis on sustainable industrial practices, the HGM mill stands out for its low dust emission and noise levels. The closed-circuit system prevents powder leakage, ensuring a clean and safe working environment.

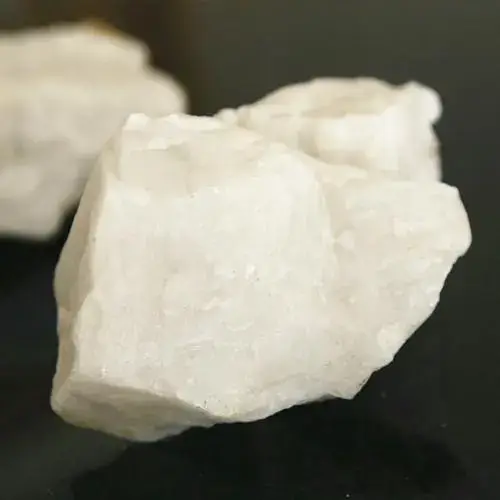

Barite (barium sulfate, BaSO₄) is a non-metallic mineral known for its high density and chemical inertness. It is primarily used in the oil and gas industry as a weighting agent in drilling fluids. Other applications include the production of barium chemicals, filler in paints and plastics, and radiation shielding materials.

Nigeria is endowed with significant barite deposits, particularly in states like Nasarawa, Benue, Cross River, and Plateau. However, much of the barite used in Nigeria’s oil industry is imported due to the lack of local processing capacity. The successful deployment of the HGM Ultra-fine Roller Mill marks a turning point in Nigeria’s efforts to develop a domestic barite processing industry, reduce import dependency, and create value-added products.

The Nigerian client required a grinding solution capable of producing 400 mesh barite powder with a minimum output of 6 tons per hour. The system needed to be energy-efficient, easy to operate, and capable of running continuously with minimal maintenance.

After a thorough technical evaluation, the HGM Ultra-fine Roller Mill was selected as the optimal solution. The mill was customized to meet the specific requirements of the project, including:

The installation process was carried out by a team of experienced engineers who ensured that all components were correctly assembled and calibrated. The commissioning phase included performance testing, operator training, and fine-tuning of the control system. The mill passed all acceptance criteria, confirming its ability to meet the client’s production goals.

Since its commissioning, the HGM Ultra-fine Roller Mill has demonstrated excellent performance in several key areas:

The client expressed high satisfaction with the mill’s performance and is considering expanding the production line with additional HGM units.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.