The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

18/07/2025 admin

Igneous Rock Crushing And Grinding Equipment typically includes jaw crushers for primary reduction and cone crushers or impact crushers for secondary crushing, followed by ball mills or vertical roller mills for fine grinding, as these durable machines must process extremely hard volcanic-formed rocks like basalt and granite.

Igneous rocks are formed from the cooling and solidification of molten rock material, either below the Earth’s surface (intrusive) or on the surface (extrusive). They are one of the three main types of rocks, along with sedimentary and metamorphic rocks.

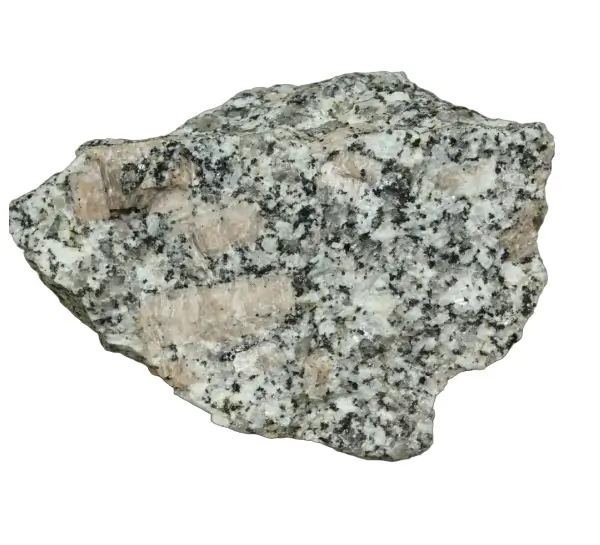

Intrusive Igneous Rocks: These form when magma cools and solidifies slowly beneath the Earth’s surface. Examples include granite, diorite, and gabbro. These rocks have coarse-grained textures due to the slow cooling process.

Extrusive Igneous Rocks: These form when lava cools and solidifies quickly at or near the Earth’s surface. Examples include basalt, andesite, and obsidian. These rocks have fine-grained or glassy textures due to rapid cooling.

Igneous rock powder is a versatile material with potential applications in various industries, particularly where strength, durability, and environmental sustainability are important considerations.

Igneous rocks, such as granite, basalt, and andesite, are known for their hardness and durability, making them challenging to crush and grind. However, various types of equipment are specifically designed to handle these rocks efficiently.

Function: Used for primary crushing of large igneous rocks.

Features: High reduction ratio, simple structure, and easy maintenance.

Application: Suitable for initial size reduction of hard rocks like granite and basalt.

Function: Used for secondary crushing after the initial reduction by jaw crushers.

Features: High efficiency, low operating cost, and ability to handle hard rocks.

Application: Commonly used for crushing igneous rocks to a finer size.

Function: Used for fine crushing and shaping of igneous rocks.

Features: High reduction ratio, uniform product size, and low wear parts consumption.

Application: Effective for rocks with high silica content like basalt.

Function: Used for crushing medium-hard igneous rocks.

Features: High efficiency, simple structure, and low cost.

Application: Suitable for crushing andesite and other intermediate hardness rocks.

Function: Used for grinding igneous rocks into fine powder.

Features: Versatile, can handle a wide range of rock types.

Application: Commonly used in cement production and mineral processing.

Ball mill host: It is the core component of the ball mill, which is equipped with grinding media (such as steel balls) and liner plates. The steel balls roll in the cylinder, grinding the materials into fine powder through impact and grinding. The liner is used to protect the cylinder and also helps to improve the grinding efficiency.

Feeding equipment: The materials to be ground are fed into the main machine of the ball mill evenly and continuously. Common ones include screw conveyors, belt conveyors, etc., to ensure that the materials can enter the grinding system stably.

Discharging equipment: The ground materials are discharged from the main machine of the ball mill and transported to the subsequent grading system or other equipment. Common ones include screw conveyors, bucket elevators, etc., to ensure the smooth discharge and transportation of materials.

Grading system: Cyclone separators or screening equipment are usually used to grade the ground materials, separate qualified fine powder from coarse powder that does not meet the requirements, and the coarse powder is returned to the ball mill for re-grinding to ensure that the product particle size meets the requirements.

Dust removal system: It is used to collect dust generated during the grinding process, reduce dust emissions, reduce environmental pollution, and also help improve the operating efficiency and safety of the equipment. Common ones include bag dust collectors, etc.

Control system: realize automatic control of the entire grinding system of the ball mill, including the start, stop, speed regulation of the motor, and the linkage control of various components, etc., to improve the operating efficiency and convenience of the equipment. The control system of a modern ball mill can achieve different levels of automatic management according to production needs.

Function: Used for grinding igneous rocks into fine powder.

Features: Compact design, easy operation, and low maintenance.

Application: Suitable for small to medium-scale grinding operations.

Main unit: including core grinding components such as grinding rollers and grinding rings, which are the key parts for material grinding. Its grinding pressure is 10% higher than that of the previous generation of mills, and the grinding area is increased by 15%-20%. The layout of the grinding rollers has been optimized to increase sufficient grinding space.

Reducer: As a power transmission mechanism, the motor speed is reduced by the gear reducer to obtain greater torque and provide power support for the operation of the mill.

Powder selector: used to classify the ground materials, separate qualified fine powder from unqualified coarse powder, and ensure that the product particle size meets the requirements.

Cyclone powder collector: used to collect qualified fine powder after grinding, separate the powder from the airflow through the action of airflow, and realize the collection and transportation of materials.

Dust collector: used to collect dust generated during the grinding process, reduce dust pollution, protect the environment, and also help to improve the operating efficiency and stability of the equipment.

Fan: provides the necessary airflow for the grinding system, so that the material can be carried away and classified by the airflow during the grinding process, and also helps to maintain the negative pressure state of the system to prevent dust leakage.

Electric control cabinet: used to control the operation of the entire mill system, including the start, stop, speed regulation of the motor, and the linkage control of each component, etc., to achieve automatic operation and monitoring.

Connecting pipe: used to connect various components to form a complete material conveying and air circulation system to ensure that materials and airflow can flow smoothly between various components.

Function: Used for grinding igneous rocks into fine powder.

Features: High efficiency, low energy consumption, and large capacity.

Application: Suitable for large-scale grinding operations.

Main machine: including grinding rollers, grinding rings, etc., is the main place for material grinding. The grinding roller rolls in the grinding ring and grinds the material into ultrafine powder through extrusion and grinding.

Hammer crusher: used to pre-crush large pieces of material to a suitable size for subsequent grinding.

Elevator: lifts the crushed material to the storage hopper to provide material supply for the grinding process.

Storage hopper: temporarily stores materials to ensure that the materials can enter the grinding host evenly and continuously.

Vibrating feeder: feeds the material into the grinding chamber of the grinding host evenly and quantitatively to ensure the stability and continuity of the grinding process.

Analyzer: used to classify the ground materials. The materials are screened by the high-speed rotating impeller. The unqualified coarse powder is returned to the main machine for re-grinding, and the qualified fine powder is collected in the cyclone powder collector.

Cyclone powder collector: collects the qualified fine powder screened by the analyzer, separates the powder from the airflow through the action of the airflow, and realizes the collection of the product.

Pulse dust removal system: used to collect the dust generated during the grinding process, reduce dust emissions, reduce environmental pollution, and also help improve the operating efficiency and safety of the equipment.

High-pressure fan: provides airflow power for the entire grinding system, so that the materials can complete the grinding, classification and collection processes under the action of the airflow.

Air compressor: provides high-pressure gas for the pulse dust removal system to clean the dust on the filter bag and ensure the normal operation of the dust collector.

Electronic control system: realizes the automatic control of the entire grinding system, including the start, stop, speed regulation of the motor, and the linkage control of various components, etc., to improve the operating efficiency and operation convenience of the equipment.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.