The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Output Size: 0-200 mm

Feed size: 350 mm

Capacity: 50-260 t/h

Application: Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganeseore, refractory material, glass, etc.

The PF series impact crushers adopt the technology of domestic traditional impact crushers. After years‘ design and optimization, such crushers boast more excellent performance and more reliable operation. It acts as medium and fine crushing equipment, most widely used domestic and abroad for medium hard and soft materials.

After optimal design of the crushing chamber and rotor, the PF series impact crushers have won significant improvement on the equipment capacity and finished product grain shape over the traditional impact crushers, using mechanical adjustment of the impact frame and rotor spacing to achieve simple and reliable control and operation.

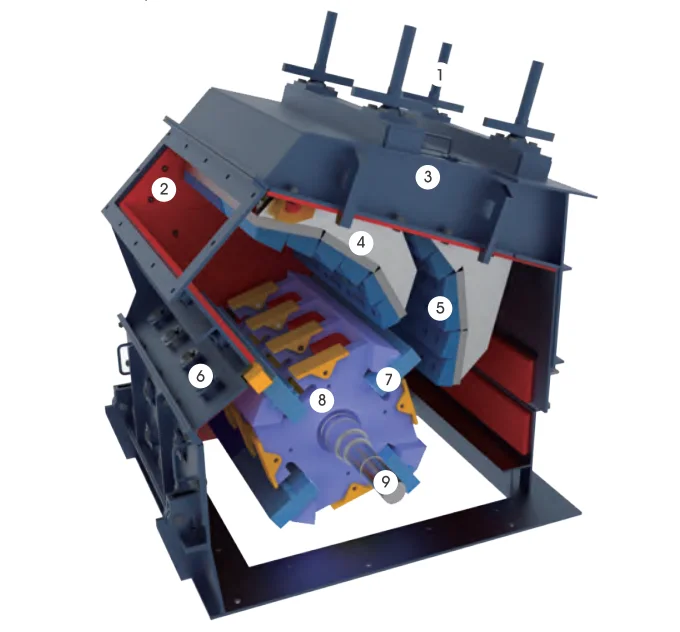

1. Adjustment device

2. Lining plate

3. Rear frame

4. Impact rear

5. Impact plate

6. Front frame

7. Hammer bar

8. Rotor

9. Main shaft

1. The impact crusher can effectively deal with a large amount of moisture content of the material to prevent the crusher from clogging.

2. The impact crusher is not only suitable for soft materials but also for larger hardness.

3. The impact crusher can be easily adjusted and flexibly discharge particle size adjustment range.

4. The impact crusher wears less parts than the hammer crusher, and the utilization rate is higher and the metal rate is higher.

5. The spare parts of the impact crusher are easy to replace, and the maintenance cost is correspondingly reduced.

| Model | Rotor Φ×L(mm) | Feed Opening(mm) | Max Feeding(mm) | Capacity (t/h) | Power (kw) | Motor Model | Machine Size(mm) |

|---|---|---|---|---|---|---|---|

| PF1010 | F1000 × 1050 | 400 × 1080 | 350 | 50-80 | 4-75 | Y280S-4/75 | 2455 × 2086 × 2800 |

| PF1210 | F1250 × 1050 | 400 × 1080 | 350 | 60-120 | 6-110 | Y315L1-6 / 110 | 2590 × 2050 × 2810 |

| PF1214 | F1250 × 1400 | 400 × 1430 | 350 | 80-160 | 6-132 | Y315L2-6 / 132 | 2590 × 2400 × 2810 |

| PF1315 | F1300 × 1500 | 860 × 1520 | 350 | 120-260 | 6-200 | Y355M3-6 / 200 | 2930 × 2760 × 3050 |

Model: PF

Accepted delivery terms: FOB, CFR, CIF, EXW, CPT, DDU, express

Acceptable payment currency: USD

Acceptable payment methods: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.