The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Capacity: 0.1-50 t/h

Max feeding size: 1-65 m³/min

Processing ability: 0.1-50 t/h

Range of application: gas, powder

Application: gas, powder

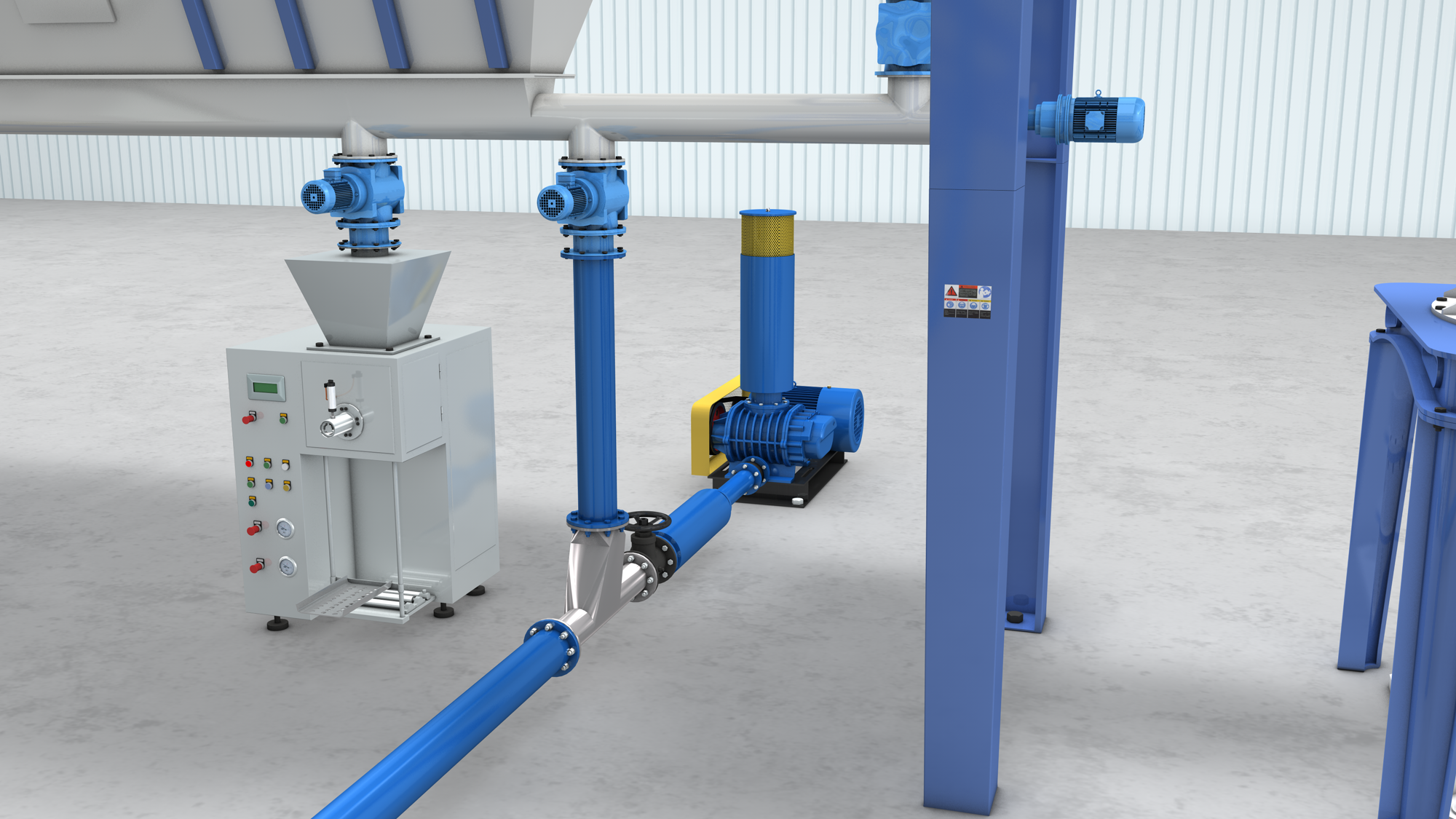

Pneumatic Conveying Equipment, which takes Roots blower as the air source, is designed specifically for close distance and continuous transporting.

Transporting distances are generally horizontal distance ≤ 300 m, vertical distance 30 m.

It is suited for conveying powder specific gravity ≤ 1.3, fineness ≥ 60 meshes, moisture content ≤ 5%, under the highest instantaneous temperature ≤ 250 ℃ working conditions, the maximum throughput is 60 t/h.

It also can be used in nesting conditions for single-point or multi-point requirements.

The equipment is with long life, low operation and maintenance costs are small, is easy controlling, widely used in mining, building materials, coal, chemical, and other industries.

The air delivery system uses the principle of gas-solid flow fluidization, jet technology, combined with differential pressure principle, to finish this work in progress.

Taking the electric rotary feeder as the feeding device, the material evenly is put into the mixing chamber.

At the same time, the Roots blower jet the high-speed airflow of materials into the acceleration chamber, the suspended flow into the conveying pipeline transport to in silos.

According to the separated feed gas, powder falls under silo gases into the atmosphere, in order to achieve powder material handling purposes.

1. Variable arrangement of the pipe makes the production craft process more reasonable.

2. The system is sealed and leads too little flying dust, its benefits for environment protection.

3. Few movement parts, convenient maintenance, automatic control can be realized easily.

4. High efficiency of transportation reduces the cost of packing, loading, and unloading.

5. Make the material avoid being damped, polluted, damaged, and mixed with other material, the quality of conveying is assured.

6. Various operation processes can be realized meanwhile for the conveying, such as mixture, crush, grade, dryness cooling, and dust collection.

7. Send the material from a couple of places to one place and from one place to a couple of places, realize far distance operation.

8. For the material with erratic chemical character, can adopt inertia gas conveying.

|

Model |

ST-LXB-0.5 |

ST-LXB-2 |

ST-LXB-5 |

ST-LXB-10 |

ST-LXB-15 |

ST-LXB-20 |

ST-LXB-30 |

ST-LXB-40 |

ST-LXB-50 |

||

|

Capacity(t/h) |

0.1~0.5 |

0.5~2 |

2~5 |

5~10 |

10~15 |

15~20 |

20~30 |

30~40 |

40~50 |

||

|

blast capacity (m³/min) |

1.0~3.0 |

8.0~12 |

10~15 |

12~18 |

14~23 |

18~30 |

20~38 |

35~50 |

40~65 |

||

|

Inlet pipe diameter |

DN40/ DN50 |

DN100/ DN125 |

DN125/ DN150 |

DN125/ DN150 |

DN125/ DN150 |

DN150/ DN175 |

DN150/ DN200 |

DN200/ DN250 |

DN200/ DN300 |

||

|

velocity in pipe (m/s) |

13~16 |

||||||||||

|

Pressure (kpa) |

≤78 |

||||||||||

|

Body material |

Cast iron, cast steel, stainless |

||||||||||

|

Motor(kw) |

0.5 |

1.5 |

2.2 |

2.2 |

2.2 |

3.0 |

3.0 |

3.0 |

4.0 |

||

|

Weight (kg) |

650 |

770 |

960 |

1100 |

1100 |

1200 |

1300 |

1450 |

1600 |

||

The world’s largest mining machine showroom

30+ years of development history

Quality first, customer first

Perfect service and strong strength

Processing ability: 0.1-50t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.