The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 1-20 T/H

Product features: The mill is high-yield and efficient, environmentally friendly and energy-saving, high grading efficiency, a wide range of finished products, a high degree of automation, high reliability, convenient maintenance

Quartz ultrafine vertical mill has the characteristics of stable operation, energy-saving, and environmental protection, large output, intelligent and controllable. The powder produced by this ultrafine vertical grinding mill has high whiteness, good ball shape, and high fine powder content, which meets the needs of many high-end powder industries and is popular in the high-end powder processing field.

also called ultrafine vertical grinding mill, ultrafine vertical roller mill

Model: CLUM

Adjustable fineness: 150-3000 mesh

Output: 1-20 t/h

Processable materials: non-metallic ores with Mohs hardness less than 7 (marble, dolomite, mica, calcite, limestone, talc, barite, bentonite, etc.), bamboo, shells, coconut shells, cocoa shells, etc.

Features: The mill is high-yield and efficient, environmentally friendly and energy-saving, high grading efficiency, a wide range of finished products, a high degree of automation, high reliability, convenient maintenance, and low operating cost. It is a piece of ideal equipment for the large-scale production of ultrafine powder.

The main component of quartz is silicon dioxide, which is colorless and transparent and has a hard texture. The physical and chemical properties of quartz are very stable and are widely used in various industrial fields.

Quartz powder is a powder that meets the requirements of use and is processed from pure quartz through multiple processes such as crushing, sorting, cleaning, acid treatment, high-temperature melting, medium crushing, fine grinding, grading, and iron removal.

Quartz powder has a wide range of applications due to its high whiteness, no impurities, and low iron content.

① Glass: The main raw materials of flat glass, float glass, glass products, optical glass, glass fiber, glass equipment, conductive glass, glass cloth, and special radiation-proof glass.

② Ceramics and refractory materials: raw materials for porcelain blanks and glazes, high-silicon bricks for kilns, ordinary silicon bricks, and silicon carbide.

③ Construction: concrete, cementitious materials, road construction materials, artificial marble, cement physical performance inspection materials, etc.

④ Chemical industry: raw materials for silicon compounds and water glass, fillers for sulfuric acid towers, and fine amorphous silica powder.

⑤ Machinery: The main raw material for foundry sand, abrasive materials (sandblasting, hard abrasive paper, sandpaper, emery cloth, etc.).

⑥ Electronics: high-purity metallic silicon, optical fiber for communication, etc.

⑦ Rubber, plastic: filler (can improve wear resistance).

⑧ Coating: Filler (can improve the weather resistance of the coating).

⑨ Metallurgy: raw materials or additives and fluxes for silicon metal, ferrosilicon alloy, and silicon aluminum alloy.

⑩ Aviation and aerospace: Its internal molecular chain structure, crystal shape, and lattice change law make it have high-temperature resistance, low thermal expansion coefficient, high insulation, corrosion resistance, piezoelectric effect, resonance effect, and unique optical characteristics.

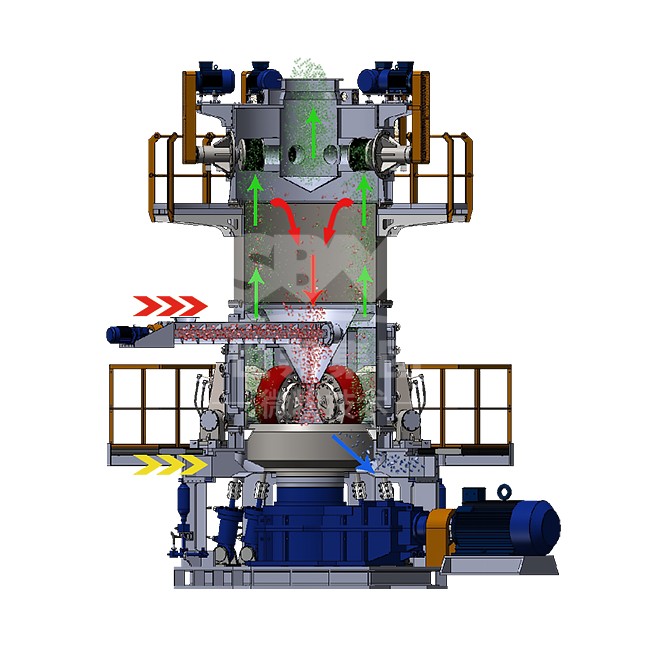

The CLUM ultrafine vertical roller mill is mainly composed of a host, a feeder, a classifier, a blower, a pipeline device, a storage hopper, an electric control system, and a collection system.

The main motor drives the grinding disc to rotate through the reducer, and at the same time, the wind enters the mill from the air inlet.

The material falls in the middle of the grinding disc through the discharge port of the screw feeder and moves evenly from the middle of the grinding disc to the edge under the action of centrifugal force.

When the material passes through the grinding roller table area on the grinding disc, it is crushed by the grinding roller, and the bulk material is directly crushed, and the fine material is squeezed to form a bed for inter-particle crushing.

The crushed materials continue to move to the edge of the milling disc until they are carried away by the strong air current at the wind ring. The larger granular materials fall back to the grinding disc and continue to be crushed.

When the material in the airflow passes through the upper separator, under the action of the rotor blades, the coarse particles return to the grinding disc for grinding.

The qualified fine powder exits the mill along with the airflow and is collected by the powder collector of the system. The powder is the product produced by the ultrafine vertical grinding mill.

When the iron and other sundries mixed into the material move to the edge of the grinding disc, they cannot be blown up by the wind due to their own weight.

They fall to the lower cavity of the grinding machine and are scraped into the slag discharge port by the scraper installed at the bottom of the grinding disc. Finally, exhaust from the machine.

● Less comprehensive investment

The CLUM ultrafine vertical grinding mill integrates crushing, drying, grinding, powder selection, and conveying into one, with a compact layout, covering an area of about 50% of the ball milling system. And can be arranged in the open air, greatly reducing investment costs. The system design is simple and reasonable, which can save unnecessary equipment investment and reduce the total equipment investment.

● All-round optimization, lower operating cost

SBM started research from various angles such as the grinding efficiency of ultrafine vertical roller mills, powder drying, wearing parts, maintenance, and replacement parts, and finally achieved lower energy consumption, stronger drying capacity, lower core parts wear, and better maintenance. Convenient and save the operating cost of equipment for customers.

● The grinding time is short, the iron content is less, and the quality of the finished product is higher

The residence time of the material in the ultrafine vertical grinding mill is short, which reduces repeated grinding. The particle size and chemical composition of the product can be better controlled, which is convenient for stabilizing the product quality; at the same time, the grinding roller and the grinding disc are not in direct contact, and the iron content in the product is low, which effectively guarantees The whiteness and purity of the material.

● High environmental protection standards, more automation

The equipment runs stably with low vibration and low noise. The vertical roller mill is fully sealed and works under negative pressure, no dust spills, clean environment, and emission standards far exceed international standards. Equipped with an expert automatic control system to realize free switching between the remote control and local control, easy operation, and labor-saving.

● Digital processing, higher precision

SBM has a number of CNC machine tool production lines, which realize digital control from steel plate cutting, bending, planing, milling to painting. The machining accuracy is high, and some core components are accurate to touch or even higher standards.

● Original parts supply, no excellent operation

SBM is a powerful enterprise integrating production and sales. We are responsible for every piece of equipment we produce. Provide customers with technical services and original parts supply services throughout the product life cycle. Guarantee every customer’s production without worries.

| ModelItem | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 6 | 6 | 6 |

| Power of classifier (Kw) | 6X15 | 6X22 | 8X22 |

| Main unit power (Kw) | 220-250 | 315-355 | 355-410 |

| Blower power (Kw) | 180-200 | 250-280 | 325-410 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding material | <3% | <3% | <3% |

| Less than 2μm=30% output (t/h) | 9-12 | 12-16 | 14-18 |

| Less than 2μm=45% output (t/h) | 5.5-7.5 | 7-9 | 10-12 |

| Less than 2μm=60% output (t/h) | 3-4 | / | / |

Material: base on calcite

Particle size distribution: measured by microlayer diffraction particle size analyzer in British Malvern 3000 instruments

Model: CLUM

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.