Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

Discharge fineness: 80-600 mesh

Feed size: <35 mm

Output: 0.4-35 t/h

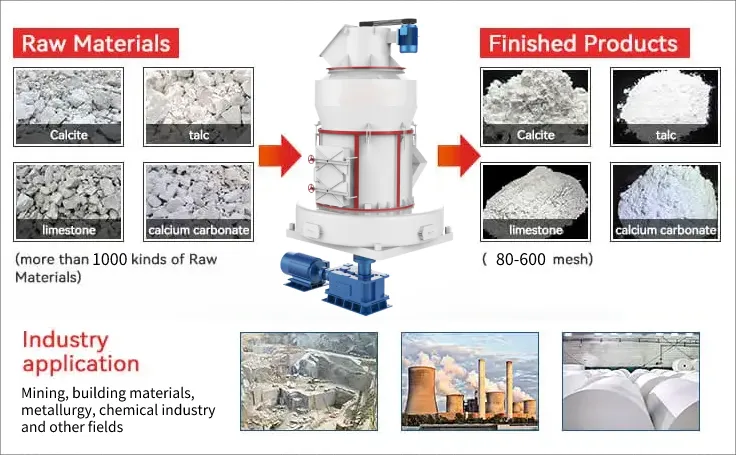

Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 7

Product features: Strong systematicness, high screening rate, smooth transmission, high wear resistance and convenient maintenance

Industrial Raymond mill, also known as YGM Raymond mill and Raymond machine, is a high efficiency pulverizing mill that replaces ball mills to process ore powder. The product has outstanding advantages such as strong systematicness, high screening rate, smooth transmission, high wear resistance and convenient maintenance. It is widely used in the grinding and processing of mineral materials in mining,

Raymond mill is widely used in the powder processing of barite, calcite, potassium feldspar, talc, marble, limestone, ceramics, glass and other non-flammable and explosive materials with Mohs hardness not greater than 7 and humidity below 6%. The fineness of the finished product is between 80 and 600 mesh. Through the joint action of the analyzer and the fan, it can meet the requirements of different users.

1. High efficiency of one-time grinding:

Using large grinding rollers, compared with the traditional Raymond mill of the same specification: the power remains unchanged, the grinding force is increased by 30%, and the primary grinding efficiency is improved.

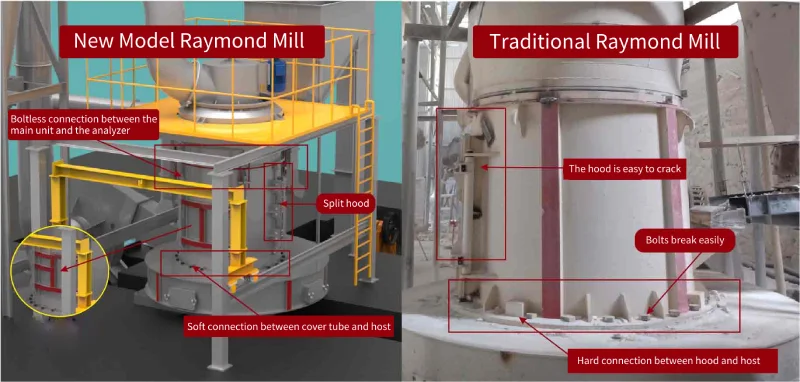

2. Soft connection structure under the cover tube, the cover tube will never crack:

The traditional mill hood and the main engine bolts are hard connected, and the vibration transmitted to the hood can easily cause the hood to crack, and the bolts are fatigued and fractured by shearing force.

The pulverizer adopts a separate cover cylinder, which is fixed with bolts of the analyzer, and the cover cylinder is softly connected to the host. During the use process, the cover cylinder is free from force and vibration, so that the cover cylinder will never crack.

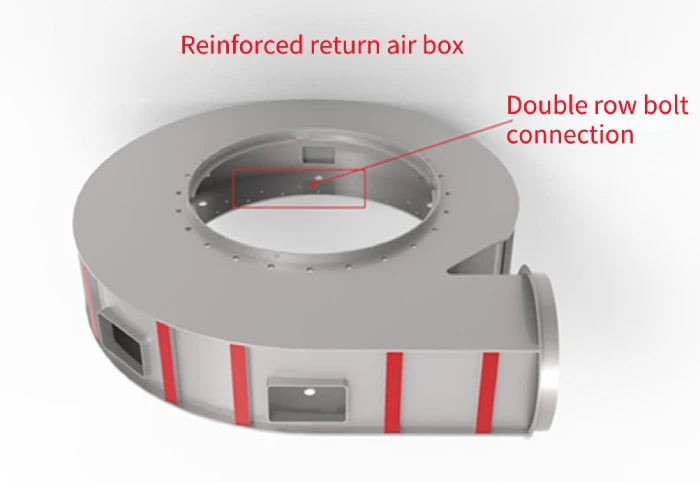

3. Reinforced air return box, double-row bolt connection

4. The central shaft of the main engine will never wear out, and the replacement of the seals on the lower part of the central shaft of the main engine is simple and convenient:

◆ For the sealing part of the central shaft of the traditional Raymond mill, after working for a certain period of time, the skeleton oil seal of the central shaft wears and forms grooves, resulting in the leakage of lubricating oil at the sealing part.

When replacing the oil seal, the main engine must be disassembled, and the center shaft frame must be disassembled and turned upside down to replace the seal (oil seal), and the workload is larger than the replacement of the grinding ring.

◆ New type YGM Raymond mill: A new structure is used to protect the main shaft at the position where the skeleton oil seal is installed, so that the main shaft will never be worn.

If the replacement of the oil seal does not need to disassemble the main engine, the replacement of the oil seal can be completed from the maintenance groove of the reducer. Significantly save equipment maintenance time and greatly reduce labor intensity.

5. Low consumption, energy saving and environmental protection:

The main engine is equipped with a frequency converter, which can be adjusted arbitrarily according to different material conditions to achieve low noise, less power consumption of equipment, stable operation and low equipment loss.

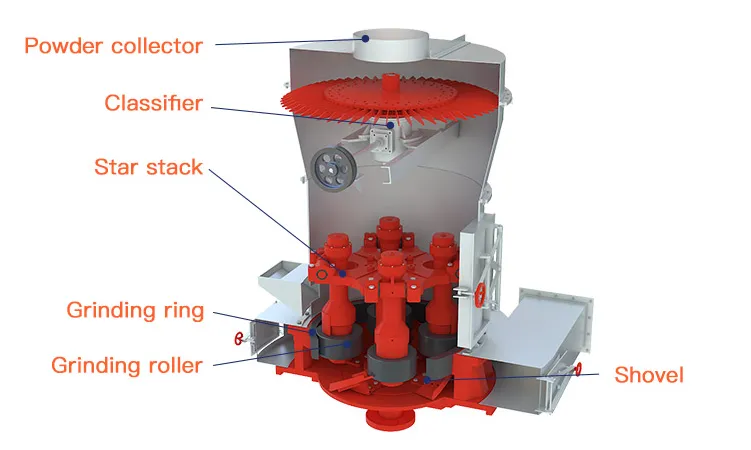

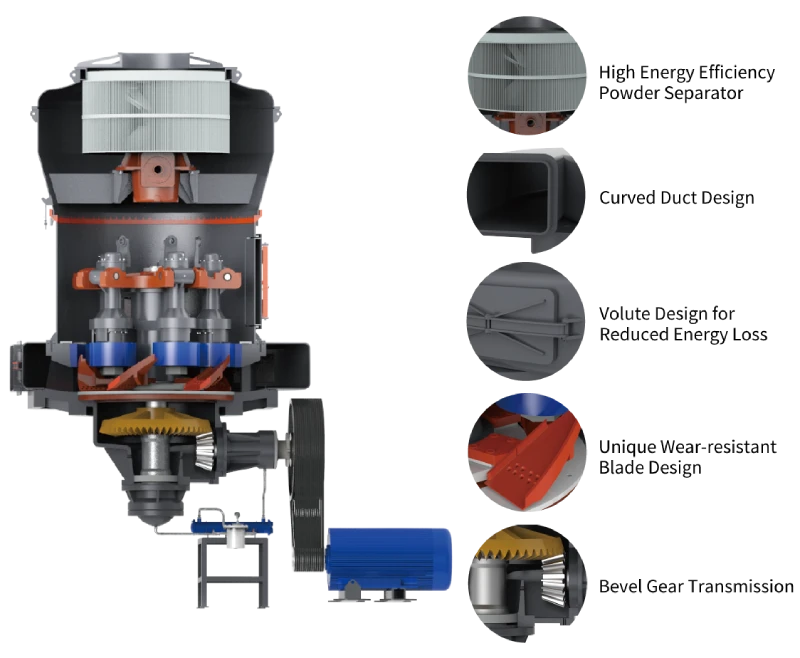

Raymond mill main machine consists of frame, air inlet volute, blade, grinding roller, grinding ring, cover and motor.

Improvements compared to traditional Raymond mills

1. Improvement of the main engine: the grinding roller and the grinding ring are increased, and the shovel blade is increased to increase the grinding surface and grinding force to increase the output.

2. Improvement of the reducer: The reducer is changed to a new type of reducer, and the speed of the main engine can be changed from a single speed to a suitable adjustment of the main engine speed according to the needs of users, and the grinding force can be increased to increase the output.

3. Improvement of the classifier: The classifier adopts a built-in large-blade cone turbine classifier, and the particle size of the finished product can be adjusted arbitrarily within 80-600 mesh, which improves the classification accuracy and airflow passing area.

4. Improvement of cyclone collector: The cyclone collector is changed to a parallel four cyclone collector, which improves the collection efficiency by more than 10%25 compared with the single cyclone.

5. Fan improvement: The blower is changed from an ordinary fan to a high-pressure fan, and the wind pressure is doubled, which greatly improves the pneumatic conveying capacity.

Features of YGM Raymond mill:

◆ One-time crushing efficiency is high

◆ Soft connection structure under the cover tube, the cover tube will never crack

◆ Reinforced air return box, double row bolt connection

◆ Low consumption, energy saving, environmental protection

◆ The output is 20-30% higher than that of domestic mills of the same type

◆ Finished mesh: 80-600 mesh (stepless adjustment)

When the Raymond mill is working, the materials to be pulverized are fed into the main machine from the feeding hopper on the side of the machine casing. Relying on the grinding roller device suspended on the main machine’s plum blossom frame, it revolves around the vertical axis and rotates itself at the same time. Due to the centrifugal force during rotation, the grinding roller of the Raymond mill swings outward and presses against the grinding ring. The shovel scoops up the material and sends it between the grinding roller and the grinding ring, and the purpose of crushing the material is achieved due to the rolling and rolling of the grinding roller.

After the Raymond mill grinds the material, the fan blows the wind into the main casing, blowing up the powder, and sorting it through the analyzer placed above the grinding chamber. The materials with excessive fineness fall into the grinding chamber for regrinding, and the fineness meets the specifications and enters the cyclone collector with the wind flow, and is discharged through the powder outlet after collection.

The air flow is collected into the fan by the return air duct at the upper end of the large cyclone collector. The air duct is circulated and flows under negative pressure. The increased air volume of the circulating air path is discharged through the exhaust pipe between the fan and the main engine and enters the small cyclone collector for purification.

| Model | Roller | Ring | Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

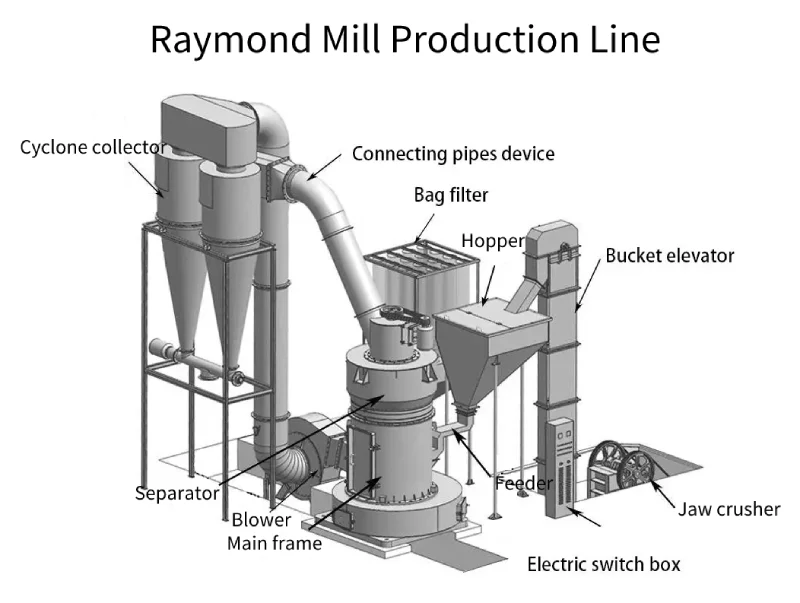

Raymond mill production line consists of Raymond mill, analyzer, piping device, blower, finished cyclone, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control motor, etc. It is used in gypsum powder processing, coal powder preparation, power plant desulfurization, etc.

Performance advantage

● Strong systematic, high screening rate

The whole machine is a three-dimensional structure, with small footprint and strong systemicity. It can form an independent production system from rough processing of raw materials to transportation to milling and final packaging. The fineness of the finished powder is uniform, and the sieving rate is as high as 99%.

● Smooth transmission, high wear resistance

The transmission device of the machine adopts a closed gear box and pulley, and the transmission is stable, and the operation is reliable. The core components are made of high-performance wear-resistant materials, which have high wear resistance and save costs.

● Easy to control and easy to maintain

Using a centrally controlled electrical system, the workshop can basically realize unmanned operation. The electromagnetic vibrating feeder is used for feeding, which is continuous and uniform, easy to adjust, saves fuel and electricity, and is easy to maintain.

● Roller and ring replacement cycle is long

The grinding roller of the Raymond mill is tightly pressed on the grinding ring under the action of centrifugal force, so when the grinding roller and grinding ring are worn to a certain thickness, the output and fineness of the finished product will not be affected, and the replacement cycle of the grinding roller and grinding ring will be long, so as to eliminate the short-term drawbacks of the replacement cycle of the wearing parts of the centrifugal pulverizer.

Raymond mill production line in Uzbekistan

Raw Material: charcoal

Capacity: 20tph

Feeding Size: 5mm

Product Size: 120mesh

Country of Client: Uzbekistan

Raymond mill production line in I ndia

Raw Material: gravel

Capacity: 20tph

Feeding Size: 5-8mm

Product Size: 80mesh

Country of Client:I ndia

Raymond mill production line in Nepal

Raw Material: glass

Capacity: 10tph

Feeding Size: 8-10mm

Product Size: 200mesh

Country of Client: Nepal

Raymond mill production line in Thailand

Raw Material: limestone

Capacity: 6-8tph

Feeding Size: 15mm

Product Size: 300mesh

Country of Client: Thailand

SBM Micro Powder Technology is an excellent mining machinery manufacturer in China. We specialize in R&D and production of industrial pulverizers: Raymond mill, coarse powder mill, ultra-fine mill, vertical mill, high pressure mill, ball mill, wet mill, etc. It is widely used in metallurgy, chemical industry, electric power, petroleum, non-metallic mineral processing and other industries, and has achieved very good feedback and is favored by many customers.

We have a complete service system and provide installation guidance and operation training. If you are interested in our products, you are welcome to consult at any time, we will be your sincere partner.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.