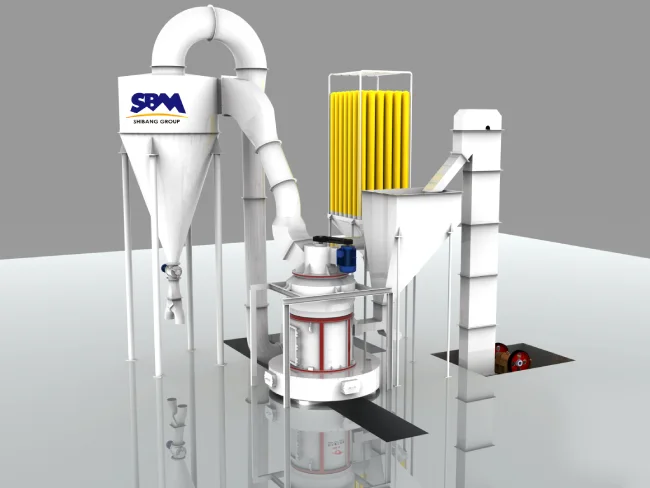

Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

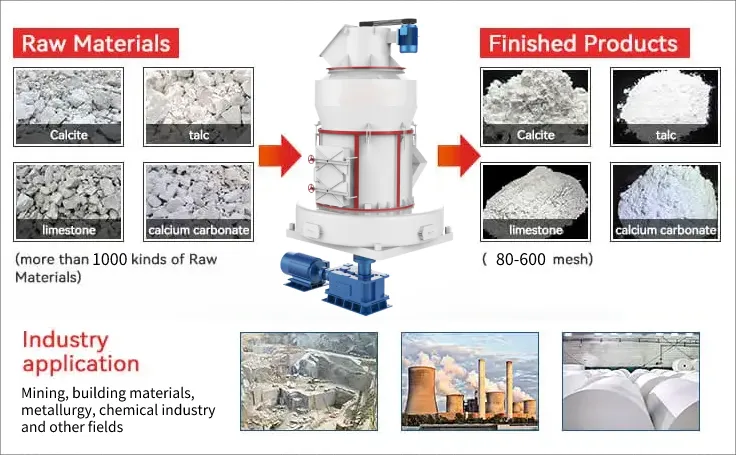

Discharge fineness: 80-600 mesh

Feed size: <35 mm

Output: 0.4-35 t/h

Materials: limestone, calcite, gypsum, potassium feldspar, marble, quartz, kaolin, cement, construction waste and thermal insulation materials, etc.

Product features: It has the characteristics of small size, good quality, low price, high efficiency and more environmental protection

Dolomite is the main constituent mineral of dolomite. According to its purity, it is white and gray, with a certain vitreous luster. After being processed, dolomite is widely used in building materials, chemical industry, environmental protection, energy saving, medicine, construction, decoration, agriculture and other fields, and has extremely important industrial value.

Dolomite Raymond Mill is a high-quality grinding mill designed by introducing mature technologies from Germany and America according to the characteristics of dolomite. It has the characteristics of small size, good quality, low price, high efficiency and more environmental protection.

Raymond mill is suitable for grinding all kinds of ores, such as: limestone, calcite, gypsum, potassium feldspar, marble, quartz, kaolin, cement, construction waste and thermal insulation materials, etc. Mohs hardness is less than 9.3, humidity is 6 High-fine milling of more than 280 materials below %.

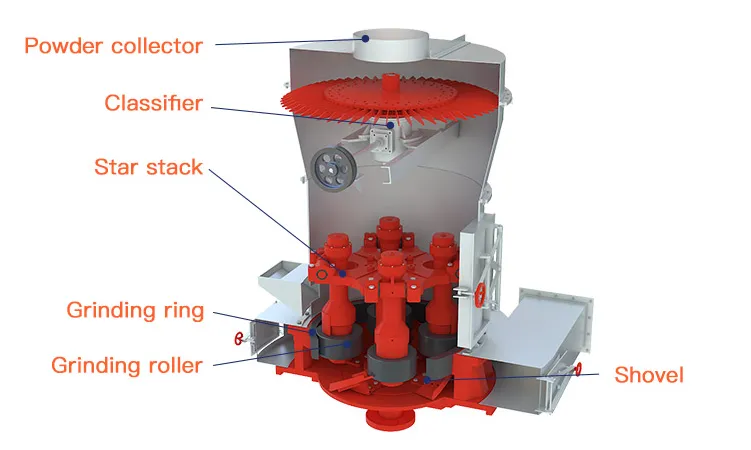

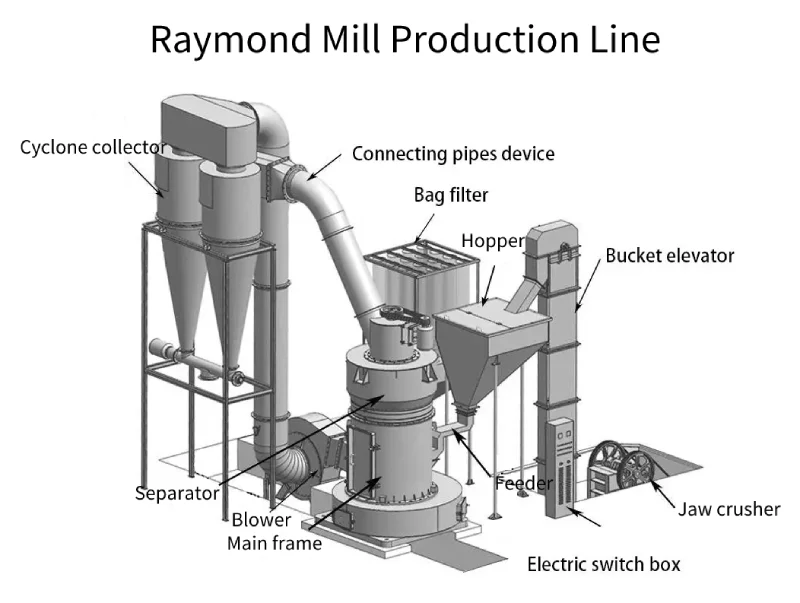

The internal structure of the dolomite Raymond mill is very simple. It is mainly composed of a main engine, a blower, a motor, an analyzer, and a piping device. Inlet volute, blade, cover, etc.

1. Raymond mill has a three-dimensional structure and occupies a small area. It can form a series of independent spaces for feeding, crushing, grinding, conveying, packaging, etc., reducing labor, infrastructure, time and other costs by 30,000 to 50,000 yuan.

2. It has a sieving rate of more than 99.9%, which cannot be achieved by ordinary grinding mill. At the same time, the dolomite fine powder after grinding is uniform in texture, high in purity and less in impurities. The fineness can be freely adjusted between 80-600 mesh.

3. The core components are made of extremely high-quality materials, and the workmanship is exquisite and meticulous. Improve the durability of the equipment and prolong the life of the machine by about 4 times.

4. Centralized electrical control and high automation level can realize no manual operation in the workshop, the whole grinding process is easier, and the work quality is guaranteed.

When the dolomite Raymond mill is working, driven by the transmission device, the grinding roller device suspended on the plum blossom frame begins to move, not only revolving around the vertical axis, but also rotating itself. Such a movement force causes the grinding roller to swing outwards continuously, and finally presses the grinding ring tightly.

The crushed dolomite is fed into the machine from the feeding hopper on the side of the machine casing and is shoveled by the shovel and sent between the grinding roller and the grinding ring and is broken into powder by the continuous rolling and rolling of the grinding roller.

Then the powdered dolomite is blown up by the fan and sent to the analyzer for sorting. The dolomite that meets the fineness requirements enters the cyclone collector with the wind flow through the analyzer, and the dolomite that is too coarse will fall into the grinding chamber for regrinding. The air flow here is closed-circuit circulation, flowing under negative pressure, and is reused by the return air duct and back into the fan.

| Model | Roller | Ring | Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.