The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 0.5-45 T/H

Product features: Small footprint and low investment. The motor is waterproof and can be placed in the open air. The operation is stable, the output is stable, and the quality of the finished powder is high.

The gypsum powder ultrafine grinding mill can grind gypsum ore into gypsum powder, which is widely used in industry, construction, medicine, and other fields. The industrial ultrafine grinding mill produced by SBM runs stably, is energy-saving and environmentally friendly, can produce 150-3000 mesh gypsum powder, and its fineness can be adjusted freely.

SBM ultrafine grinding mills are popular in the production of gypsum, limestone, barite, calcite, dolomite, and other powders due to their outstanding performance advantages.

Model: HGM80, HGM90, HGM100, HGM125L, HGM1680L

Adjustable fineness: 150-3000 mesh

Output: 0.5-45 t/h

Processable materials: non-metallic ores with Mohs hardness less than 7 (talc, marble, barite, dolomite, limestone, pumice, etc.), shells, coconut shells, eggshells, bamboo, etc.

Features: Small footprint and low investment. The motor is waterproof and can be placed in the open air. The operation is stable, the output is stable, and the quality of the finished powder is high. Simple operation and convenient maintenance. Safe and reliable, energy-saving, and environmental protection.

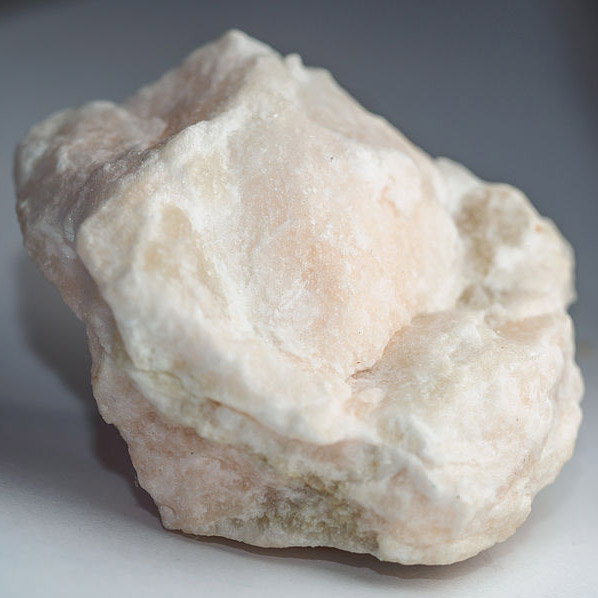

Gypsum powder is one of the five major gel materials, the main component is water-containing calcium sulfate, mostly white translucent crystals. There are many types of gypsum.

According to their different physical components, they can be divided into phosphogypsum powder, desulfurized gypsum powder, citric acid gypsum powder, and fluorogypsum powder.

According to the application, it can be divided into gypsum powder for building materials, gypsum powder for the chemical industry, gypsum powder for molds, gypsum powder for food, and gypsum powder for casting.

Gypsum is an important industrial raw material. The gypsum powder ultrafine grinding mill is used for its deep processing, and the obtained gypsum powder can be widely used in construction, building materials, industrial molds, and art models, chemical industry, and agriculture, food processing, medicine and beauty, and other fields.

As a widely used material, choosing high-performance production line equipment to process gypsum powder can improve the use of gypsum powder and bring good market and economic benefits.

In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable. Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle size requirements of the mill; then use the ultrafine mill for grinding treatment; then enter the boiling furnace for heating treatment, and finally do store the finished product.

In this process, the grinding link is very important. The quality of the gypsum grinding mill directly determines the quality of the gypsum produced. Therefore, it is especially important to use a piece of stable equipment in the process of processing the gypsum powder.

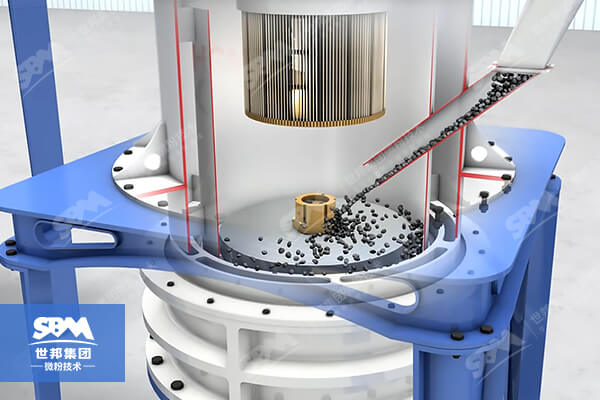

The ultrafine grinding mill is a commonly used grinding equipment in the ore industry. Superior performance, high productivity, low energy consumption, stable operation, can produce 150-3000 mesh ore powder, and the principle of the mill is scientific, it is a piece of ideal milling equipment for the ore industry.

So, what is the principle of the gypsum ultrafine grinding mill? After the material is crushed and ground, the ground powder is sieved by the classifier, the coarser fineness will fall into the main machine for regrinding, and the finer fineness will be collected by the pulse collector to become the finished product.

① High grinding efficiency, high output, low energy consumption

The newly designed grinding curve of the grinding roller and ring further improves the grinding efficiency of the HGM ultrafine grinding mill. Under the same fineness and power, the production capacity is 40% higher than that of jet mills and stirring mills, the output is twice that of ball mills, and the system energy consumption is only 30% of jet mills.

② Low probability of damage and long service life

There are no rolling bearings and screws in the grinding chamber, which eliminates the root cause of screw loosening and damage to the machine. The grinding ring grinding roller is made of special alloy material, which is more wear-resistant and has a longer life

③ 24h continuous work

The lubrication device is installed outside the main shaft, which can realize external non-stop lubrication and continuous production for 24 hours.

④ High precision of powder selection, high content of the fine powder

Equipped with a multi-head cage type powder separator to effectively improve the precision of powder selection. One screening rate can reach d97≤5μm.

⑤ Environmental protection and pollution-free

Equipped with a high-efficiency pulse dust collector, there will be no dust pollution during the operation of the entire crushing system.

| Parameters of HGM series ultrafine mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

The price of the gypsum powder superfine grinder needs to be customized according to the customer’s grinding needs. The different materials processed by the customer’s grinding project, the fineness of the finished powder, the production capacity, etc., will have different requirements for the configuration of the production line, and the price will also be different. Only by understanding this information in advance can we further formulate a reasonable plan and give an accurate price for the gypsum ultrafine mill.

Model: HGM

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.