The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size: <25 mm

Output: 0.5-45 t/h

Product features: High safety and reliability High efficiency and low consumption Environmentally friendly

HGM series ultrafine powder mill (three-ring / four-ring medium-speed micro-powder mill) is a high-efficiency and low-consumption ultra-fine powder processing equipment that successfully replaces the traditional jet mill and complex process ball mill grinding and powder selection, greatly reducing production costs. Improve the fineness of the product.

Thousands of domestic users have proved that this equipment has the advantages of superior performance, stable quality, simple operation, and convenient maintenance. It is a piece of ideal equipment for ultrafine powder processing.

① It can be adjusted arbitrarily to produce a finished powder with a fineness of 150 meshes to 2500 meshes.

② It is suitable for grinding hundreds of materials with Mohs hardness below 6.

③ The equipment investment is small, and the operation is simple.

④ The equipment can operate continuously for 24 hours.

An ultrafine powder mill is suitable for processing non-flammable and explosive brittle materials with medium and low hardness.

It can grind and process many materials such as calcium carbonate, kaolin, bentonite, talc, mica, attapulgite, barite, gypsum, graphite, etc.

Its applications have spread across many industries such as paint, papermaking, pigments, rubber, plastics, fillers, cosmetics, chemical supplies, etc.

After the large pieces of material are crushed to the required size by the jaw crusher, the material is sent to the storage hopper by elevator.

And then sent to the main grinding chamber evenly and continuously by the vibrating feeder for grinding. The ground powder is taken away by the airflow of the fan and classified by the analyzer.

The finished product that meets the fineness is collected by the airflow through the pipe, then into the large selection air collecting pipe. And then discharged through the powder outlet pipe to become the finished powder.

1. The yield is 40% higher than other mills.

2. High utilization rate of Wear material: 2-5years.

3. Adjustable particle size: 150-3000 mesh.

4. High safety and reliability: The design of the mill is rigorous, so no screw loosening to damage the machine.

5. Closed system, so it is the green and ideal equipment for environment protection.

6. Environment-friendly: The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Pre-sale

On-sale

After-sale

Free to help customers in equipment selection and scheme design.

You are always welcomed to visit SBM! Visit our prototype and showroom.

Strictly implement quality standards, and guarantee the quality of products shipped.

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery.

Overseas professional installation team provides technical guidance for equipment installation and commissioning.

Train the start-up process, teardown method, common problems and maintenance service.

Professional after-sales service team, 24 hours response to customer needs.

CE, ISO9001

factory sell directly

30 years experience, professional

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

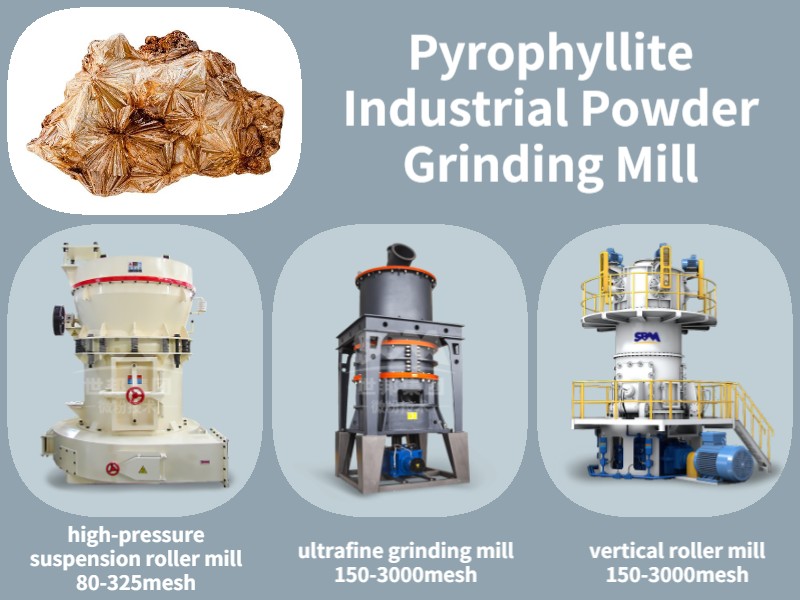

Pyrophyllite industrial powder grinding mills can grind non-metallic ores such as pyrophyllite into a coarse powder or fine powder up to 6000 mesh.

Wollastonite industrial grinding mills can grind non-metallic ores such as wollastonite into a fine powder and ultra-fine powder.

The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM. The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind non-metallic ore powder of 150-3000 mesh.

Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 150-3000 mesh.

Chalk micro powder mill can grind non-metallic ores into fine powder up to 6000 meshes. It is a highly efficient industrial micro powder grinding mill.

Sepiolite superfine powder grinding mill is a high-efficiency, energy-saving, low-consumption, and environmentally friendly industrial non-metallic ore mill. Its fineness can be adjusted between 150-3000 mesh and can be used for the grinding of sepiolite.

Model: HGM80, HGM90, HGM100, HGM125, HGM168L.

Capacity: 0.5-45t/h

Max feeding size: 25 mm

Processing ability: 0.5-45t/h

Finished size: 150~3000 meshes(5-47 micron)

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.