The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

19/10/2021 admin

The pyrophyllite industrial powder grinding mill can grind pyrophyllite into coarse powder or fine powder as required. Pyrophyllite mills include ultrafine grinding mills, vertical grinding mills, high-pressure grinding mills, coarse grinding mills, etc., which are used in production lines with different grinding requirements.

Ordinary pyrophyllite powder (80-325mesh) is usually ground by a high-pressure mill or Raymond mill; medium and high-end pyrophyllite powder (150-3000mesh) is usually ground by a superfine powder mill or vertical roller mill, and pyrophyllite coarse powder (less than 8mm) is usually ground by a coarse grinding machine.

Pyrophyllite is an aluminosilicate mineral. The color is generally white, slightly yellowish or greenish, with white streaks. Glass luster, with a pearl-like halo. The hardness is small (1~1.5 or 1~2), with a smooth feeling. It has stable chemical properties, good heat resistance, and insulation, and is a dielectric material for sealing and transmitting pressure.

Used as: It is widely used in ceramics, metallurgy, building materials, chemical industry, light industry, and other industrial sectors.

Adding pyrophyllite to the ceramic blank can reduce the firing temperature, shorten the drying time, increase the firing strength, reduce glaze defects, and make the ceramic perfect.

Production fineness: about 200 mesh

Pyrophyllite contains silicon dioxide and aluminum oxide, does not melt when heated, and is a raw material for the manufacture of aluminum silicate refractory materials.

Production fineness: 3mm

Refractory materials, refractory bricks

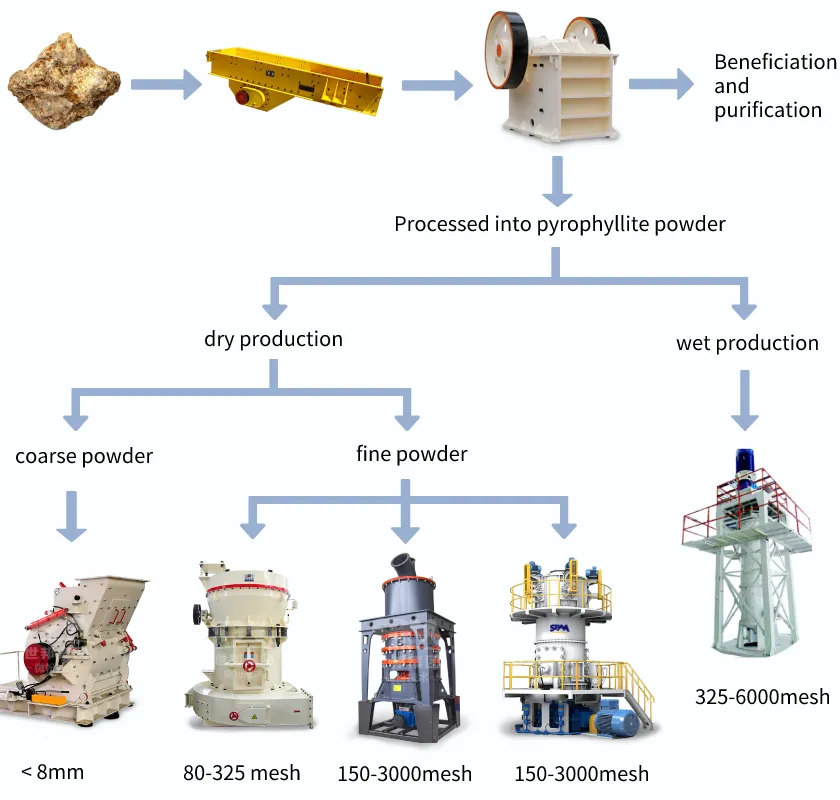

The crushing and grinding of pyrophyllite have two purposes: one is to prepare for the beneficiation and purification operation, to prepare the pyrophyllite powder raw material that dissociates from the impurity mineral monomer. The second is to directly process pyrophyllite powder products for pyrophyllite whose purity can meet the requirements of the application field.

Pyrophyllite processing process:

1. Crushing stage: Large pieces of material are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding stage: Small pieces of material that meet the conditions for entering the mill are uniformly and quantitatively fed into the grinding chamber of the mill through the conveying and feeding system, and pulverized in the grinding cavity.

Main production equipment for ultra-fine pyrophyllite (dry production)

HGM ultrafine grinding mill can produce medium and high-end pyrophyllite powder of 150-3000 mesh, simple operation, convenient maintenance, and fineness can be adjusted freely.

CLUM ultra-fine vertical roller mill can produce high-end pyrophyllite powder of 150-3000 mesh, with high fine powder content, good powder shape, high whiteness, and fineness that can be adjusted freely.

The high-pressure suspension roller mill can produce ordinary pyrophyllite powder of 80-325 mesh, with stable operation and low investment.

Pyrophyllite wet purification (wet production)

After flotation or wet magnetic separation, the ultra-fine crushing process can be carried out, and the wet process can be used. After the wet crushing reaches the required fineness, it is dehydrated (filtered and dried).

3. Classification stage: the ground material will be classified by the classifier along with the airflow of the system, and the unqualified powder will be classified by the classifier and returned to the main machine grinding cavity for re-grinding.

4. Powder collection stage: The powder that meets the fineness enters the powder collection system with the airflow through the pipeline, and the gas and powder are separated. The finished powder is sent to the finished product silo by the conveying device and then is packaged by a powder tanker or an automatic baler.

Coarse flour process:

Crushing stage: Large pieces of material are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

Pulverizing stage: the small pieces of material that meet the conditions of entering the mill are uniformly and quantitatively fed into the mill by the conveying and feeding system and can be formed at one time.

Pyrophyllite powder is a product of pyrophyllite that is collected, selected, analyzed, ground, and mixed evenly according to the needs of the application. The powder has a creamy feel and is used as an additive to mix with other pigments or to adjust pigments.

Commonly used crushers for pyrophyllite include jaw crushers, cone crushers, and impact crushers. Commonly used mill equipment mainly includes a high-pressure grinding mill, super fine powder mill, vertical roller mill, wet mill, and so on.

When pyrophyllite is used in papermaking, plastics, rubber, high-performance refractory materials, and other fields, it must be super finely crushed. At present, there are two processes for ultrafine pulverization of pyrophyllite: dry method and wet method. The dry process mainly uses high-pressure mills, ultra-fine grinding, etc.; the wet process mainly uses grinding and stripping machines and stirring mills.

The following introduces the equipment required for the more important milling link in the dry production line:

Medium and high-end pyrophyllite powder >>

Product features: ultrafine powder, wide application, the good environmental protection effect

Input size: 0-20mm

The fineness of the product: 150-3000mesh

Capacity: 0.5-25TPH

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency. The production capacity is 40% higher than that of jet mills and stirring mills, and the energy consumption is only 30% of that of jet mills.

Equipped with multi-head cage type powder concentrator. The fineness of the product can be adjusted arbitrarily between 150-3000 mesh, and the one-time screening rate can reach d97≤5μm.

The lubrication device is installed outside the main shaft, which can realize external non-stop lubrication and continuous production for 24 hours.

HGM ultrafine grinding mill is equipped with a high-efficiency pulse dust collector, so there will be no dust pollution during the operation of the entire crushing system. Equipped with silencer and anechoic room to reduce noise.

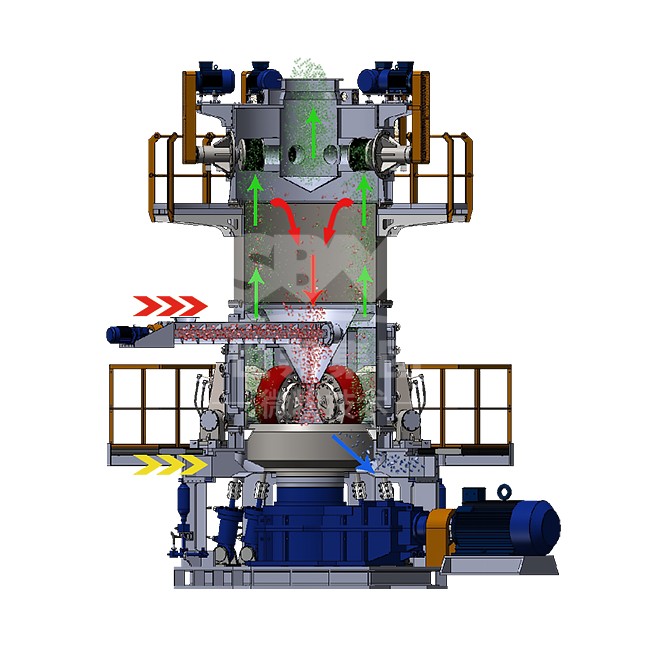

High-end pyrophyllite powder >>

Product features: higher capacity, better powder quality, better overall performance

Input size: 0-10mm

Capacity: 5-18TPH

The fineness of the product: 150-3000mesh

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

SBM specially designed a unique roller shell and liner grinding curve, which can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product.

Using a PLC control system and multi-head powder selection technology, it can precisely control the working parameters of the equipment such as grinding pressure and speed. Compared with ordinary mills, the energy consumption of this mill can be reduced by 30%-50%.

The contact point between the roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive impact caused by machine vibration and ensure the stability of operation.

Through the reversible structure and hydraulic adjustment system, the operator can easily and quickly move the grinding roller out of the machine body, inspect and replace the roller shell and liner, and perform other maintenance operations to reduce downtime losses.

Ordinary pyrophyllite powder >>

Processing ability: 0-50tph

Max feeding size: 35mm

Product Fineness: 80-325Mesh

Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, glass, etc.

Vertical structure, so it has a small footprint, strong system. Compared with other mills, it has a high passing rate – 99%.

The main drive device of the high-pressure mill adopts an airtight gearbox and belt pulley, the transmission is stable and the operation is reliable.

Important components are made of high-quality castings and profiles, ensuring the durability of the whole equipment.

The centralized control is used in the electric system, the mill can basically realize unmanned operation, and the maintenance is convenient.

Pyrophyllite coarse powder >>

Coarse Powder Grinding Mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPA into coarse powder and small particles.

High capacity and low power consumption.

Uniform particle size with high crushing and crushing ratio.

Simple structure.

Low investment, easy operation.

The following introduces the equipment required for the more important milling link in the wet production line:

Ultrafine powders, reach 2 microns with a content of 90% for milling one time.

Has a large output, high efficiency, low energy consumption, environmental protection, and other features.

Vertical-shaped star wheel reducer higher transmission efficiency, run more smoothly.

Low consumption of grinding media, non-polluting. The temperature is low for finished products, good liquidity.

Compact structure, suitable height, easy operation and maintenance, stable production, automatic controlling is optional.

Reasonable equipment selection and scientific configuration, the production line covers a small area, runs more smoothly, reduces failures, and reduces investment capital by about 40%;

The whole process of the production line is automated so that there is no on-site operator, and the operation and operation of the equipment can be freely controlled through the remote;

High efficiency, low cost, large output, the finished pyrophyllite powder has uniform texture, adjustable fineness, high purity, and the sieving rate is over 99.9%;

The milling equipment is fully enclosed and under negative pressure. The operation process is free of dust pollution and low noise, realizing green production.

SBM can customize non-metallic ore grinding/crushing and screening solutions for you free of charge according to your needs.

Strong strength, more than 30 years of R&D and manufacturing experience, covering 120+ countries and regions.

The systematic and standardized process, from service to preparation to delivery, is safer and more efficient.

Strong production capacity, digital processing, and higher precision.

SBM’s business covers production and sales and is responsible for every machine it produces. We can provide customers with technical services related to products and original spare parts to ensure worry-free operation.

Our factory:

Payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

According to chemical and mineral composition, pyrophyllite can be divided into wax stone pyrophyllites, diaspore pyrophyllite, kaolinite pyrophyllite, siliceous pyrophyllite, etc.

The main mineral of pyrophyllite is pyrophyllite, which accounts for 90%. The others are chalcedony, limonite, and diaspore, which can be used to make ceramics, sculptures, fillers, coatings, and refractory materials.

The main mineral of diaspore-based pyrophyllite is pyrophyllite, and the secondary mineral is diaspore, which contains trace amounts of limonite, rutile, etc., which can be used to make refractory materials and glass crucibles.

Kaolinite pyrophyllite is the main mineral kaolin, and the secondary mineral is pyrophyllite, which contains trace amounts of limonite, rutile, etc., which can be used to make ceramics and refractory materials.

The main mineral of siliceous pyrophyllite is pyrophyllite, the minor minerals are quartz, chalcedony, and the trace minerals are limonite, etc., which can be used to make ceramics, refractory materials, fillers, etc.

Pyrophyllite powder is a silicate composed of silicon dioxide and aluminum oxide. It has a high melting point, does not shrink at high temperatures, has stable chemical properties, is non-toxic, resistant to corrosion, has no expansion and plasticity in water, and is good It has the characteristics of low sintering temperature, low electrical conductivity, low expansion coefficient and so on.

Pyrophyllite is one of the important production raw materials for functional ceramics (super-hard ceramics, ultra-high-voltage electric porcelain), new green refractory materials, high-performance glass fibers, super-hard materials (man-made diamonds), etc. It is an important new energy source (wind power, fan Blade) materials and new functional materials. It is also suitable for plastics and related modifications, coatings and infrared blocking materials, rubber, inks, sealants, refractory materials, and flame retardant materials, personal care, agricultural fertilizers, papermaking, and other industries.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.