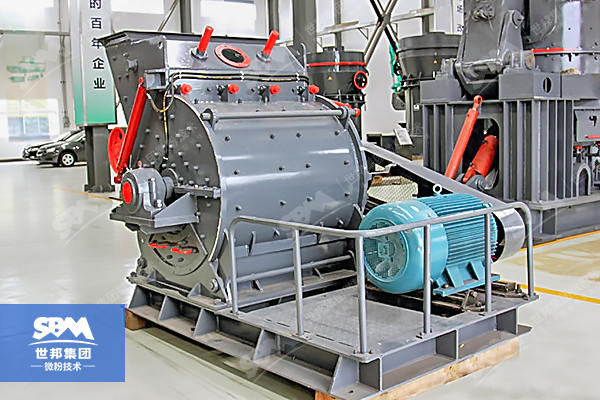

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: <8 mm

Feed size.: <80 mm

Output: 40-70 T/H

Product features: High capacity and low power consumption; Low investment, easy operation

Coarse Powder Grinding Mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPA into coarse powder and small particles.

It is widely used in metallurgy, mining, chemical, cement, coal, sand-making, construction, refractory materials, and ceramic industries.

Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, glass, etc.

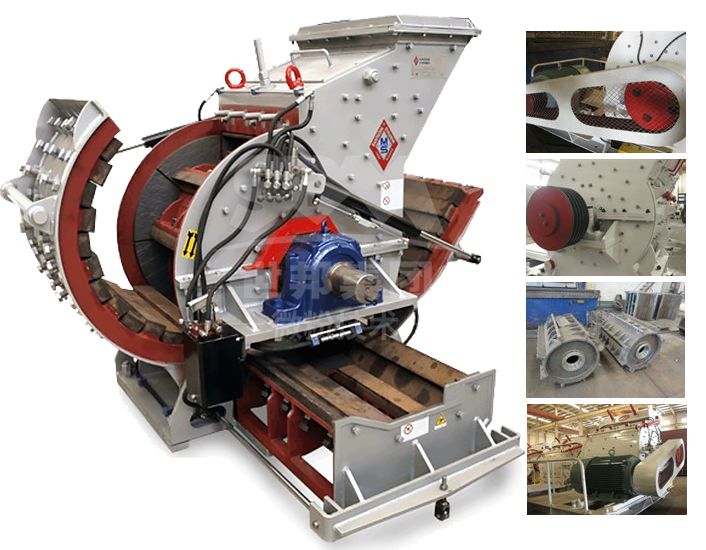

European Coarse Powder Mill mainly consists of frame, rotor, support iron, and grate bars. The frame is divided into two parts: the upper part and the lower part, which are welded by steel plates after being cut.

Liners made of high manganese steels within the frame can be replaced after being worn out. The rotors consist of turn plates, pin shafts, and hammers which are grouped regularly in the main shaft.

The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers.

Large materials entering the crusher through the feed inlet are firstly crushed by the high-speed hammers and then thrown fiercely to the support iron for further crushing.

Qualified materials crushed will be screened out and exit from the gap of the grate bars, while the unqualified will be left in the crushing cavity to be further hammered and ground until reach the standard size.

The size of the final product can be adjusted by changing the grate bars. The gap between the rotors and the grate bars can also be adjusted according to different requirements. To avoid the plugging of the crusher, the proportion of water for the crushing materials is no more than 20%.

| Type | PC4008-75 | PC4012-90 | PC4015-132 |

| Rotor Diameter /mm | 750 | 900 | 1150 |

| Rotor Width/ mm | 800 | 1200 | 1500 |

| Rotor Speed/ r/min | 800-1000 | 800-1000 | 550-800 |

| Max Feeding Size/mm | <50 | <60 | <80 |

| Finished particle size /mm | 0-3 | 0-3 | 0-8 |

| Capacity / t/h | 10-30 | 30-60 | 50-100 |

| Power /kw | 55-75 | 75-90 | 45 |

| Hammer Number /pieces | 18 | 32 | 32 |

| Dimension L*W*H/mm | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 |

1. High capacity and low power consumption.

2. Uniform particle size with high crushing and crushing ratio.

3. Simple structure.

4. Low investment, easy operation.

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

Strict implementation of quality standards, quality assurance of ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

CE, ISO9001

factory sell directly

30 years experience, professional

Ultrafine vertical mill is a high-efficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc

Carbon black is a light, loose and fine black powder that contains carbon substances. It can be used as a black dye to make ink, paint, rubber material, etc. Carbon black ultrafine mill is also called (three-ring four-ring) medium-speed ring roller micro-grinding machine. It adopts a graded continuous grinding method to grind the material multiple…

Stone powder making machine is an ultrafine industrial grinding mill, used to grind solid materials into ultrafine powder, such as calcite etc.

High pressure grinding mill, also known as high pressure roller mill, can grind non-flammable and explosive materials into fine powder.

The three ring medium speed micro powder mill can grind the material to an ultra-fine particle size of more than 3000 mesh through fine processing of the material. It is a common equipment for processing ultra-fine powder in the market.

The CLRM series dolomite powder enhanced roller grinding mill has the characteristics of stable operation, reliable operation, fineness of the finished product is widely adjusted and long service life.

Model: PCC-75, PCC-90, PCC-132

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.