The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

11/10/2021 admin

Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 150-3000 mesh. The industrial grinding mills independently developed and produced by SBM have the advantages of stable operation, high efficiency, energy-saving, and environmental protection, and long service life, etc. They are sold well at home and abroad and are widely praised.

The SBM industrial powder grinder mainly includes HGM series ultrafine grinding mills and CLUM series superfine vertical roller mills. They can both grind quartz into a fine powder, and the fineness can be adjusted freely. In addition to grinding quartz, they can also grind other non-metallic ores such as dolomite, calcium carbonate, mica, calcite, kaolin, etc. They are widely used, have good grinding effects, and are highly praised by customers.

Quartz is one of the most widely distributed minerals on the earth’s surface, with a Mohs hardness of 7. It is usually colorless, translucent, or transparent, with glass luster and fracture grease luster. After coarse crushing and fine crushing, ordinary quartz sand can be obtained, and quartz powder (refined quartz sand) can be obtained after further grinding of quartz sand. It is widely used in glass, casting, ceramics, metallurgy, construction, chemical industry, plastics, rubber, abrasives, and other fields.

After the quartz stone mined from the mine is processed, the product with a fineness of less than 120 mesh is generally called quartz sand, and the product with a fineness of more than 120 mesh is called quartz powder (refined quartz sand).

Quartz powder is a powder that meets the requirements of use, which is processed from pure quartz through multiple processes such as crushing, sorting, cleaning, acid treatment, high temperature melting, medium crushing, fine grinding, grading, and iron removal. Common quartz powders are 150mesh, 200mesh, 325mesh, 400mesh, 600mesh, 1500mesh and 2000mesh.

The flow of the quartz sand grinding production line is roughly as follows:

(silo) → vibrating feeder → jaw crusher → bucket elevator → electromagnetic vibrating feeder → quartz industrial powder grinder → finished powder (powder of different fineness, the milling equipment selected by the body is different).

Quartz powder (refined quartz sand) is processed from high-purity quartz ore. The product has the characteristics of high grade, white color and strong hardness. Quartz is washed, crushed and sieved into various specifications of quartz sand, and then ground into quartz powder.

The flow of the quartz sand crushed stone production line is roughly as follows: (silo)→vibrating feeder→(jaw crusher)→cone crusher→vibrating screen→finished crushed stone (several layers of vibrating screen, several types are available finished product).

Quartz powder (refined quartz sand) main purpose: to provide raw materials and auxiliary materials for ceramics, enamel, precision modeling, chemicals, coatings, building materials, metallurgy, high glass, metal rust removal, polishing, water treatment and other users.

The complete quartz powder production line includes crushing, screening, cleaning, industrial powder grinder, grading, purification, powder collection, noise reduction, dust removal, etc. The main introduction here is the grinding equipment in the fine grinding process. Of course, if what you need is a complete quartz powder production line, we can also make a plan for you. You only need to leave your detailed production requirements, and our professional and technical personnel will follow your needs and configure a complete production line plan for you free of charge.

Both the HGM ultrafine grinding mill and CLUM ultrafine vertical mill developed and produced by SBM can produce 150-3000 mesh quartz powder, and the fineness can be adjusted freely, which can meet the production of various fineness quartz powder.

150-3000 mesh powder >>

Product features: ultrafine powder, wide application, good environmental protection effect

Input size: 0-20mm

Fineness of the product: 150-3000mesh

Capacity: 0.5-25TPH

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

The newly designed grinding roller grinding ring grinding curve improves the grinding efficiency. The production capacity is 40% higher than that of jet mills and stirring mills, and the energy consumption is only 30% of that of jet mills.

Equipped with multi-head cage type powder concentrator. The fineness of the product can be adjusted arbitrarily between 150-3000 mesh, and the one-time screening rate can reach d97≤5μm.

The lubrication device is installed outside the main shaft, which can realize external non-stop lubrication and continuous production for 24 hours.

HGM ultra-fine pulverizer is equipped with a high-efficiency pulse dust collector, so there will be no dust pollution during the operation of the entire crushing system. Equipped with silencer and anechoic room to reduce noise.

– Case in Saudi Arabia

Material: Quartz

Fineness: 600mesh

Capacity: 10 t/h

This Arab customer plans to produce 600 mesh quartz stone powder with an hourly output of more than 10 tons. Customers contact us via the Internet. After understanding the customer’s needs, we recommended the quartz industrial powder grinder developed and produced by SBM.

Product features: higher capacity, better powder quality, better overall performance

Input size: 0-10mm

Capacity: 5-18TPH

Fineness of the product: 150-3000mesh

Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

SBM specially designed a unique roller shell and liner grinding curve, which can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product.

Using a PLC control system and multi-head powder selection technology, it can precisely control the working parameters of the equipment such as grinding pressure and speed. Compared with ordinary mills, the energy consumption of this mill can be reduced by 30%-50%.

The contact point between the roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive impact caused by machine vibration and ensure the stability of operation.

Through the reversible structure and hydraulic adjustment system, the operator can easily and quickly move the grinding roller out of the machine body, inspect and replace the roller shell and liner, and perform other maintenance operations to reduce downtime losses.

325-6000 mesh powder >>

If you need to produce higher fineness quartz powder (>3000mesh), you can use an ultra-fine wet stirring mill, which can produce up to 6000 mesh ore powder

Ultrafine powders, reach 2 microns with a content of 90% for milling one time.

Has a large output, high efficiency, low energy consumption, environmental protection, and other features.

Vertical-shaped star wheel reducer higher transmission efficiency, run more smoothly.

Low consumption of grinding media, non-polluting. The temperature is low for finished products, good liquidity.

Compact structure, suitable height, easy operation and maintenance, stable production, automatic controlling is optional.

0-8 mm powder >>

Coarse Powder Grinding Mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPA into coarse powder and small particles.

High capacity and low power consumption.

Uniform particle size with high crushing and crushing ratio.

Simple structure.

Low investment, easy operation.

SBM integrates R&D, production, distribution, and service, and attaches great importance to communication with customers. We have established a systematic and standardized service guarantee system to ensure that each service item is handled in a timely and proper manner.

SBM adheres to the principle of providing customized design solutions for each customer. Relying on the professional knowledge of the sales manager and the full life cycle service of the product, help customers overcome difficulties in equipment procurement, operating cost accounting, operation management, and after-sales service acquisition, improve profitability, and achieve sustainable business development.

Our factory:

Our services:

pre-sale service

SBM provides customers with free on-site exploration services, including material testing and on-site evaluation. SBM also provides complete analysis reports and project descriptions to ensure that the solution design better meets customer requirements and has higher security.

solution

SBM provides customers with professional integrated solutions based on the results of professional on-site investigations and displays the CAD drawings and 3D drawings of each solution. With strong R&D capabilities, SBM can provide customized equipment to meet the needs of special projects.

Project management

We assign a project manager for each project to provide professional project management services, including strict project schedule management and strict internal production management, to ensure that the project is completed on time; to provide customers with detailed construction schedules and plans to ensure production line construction completed on time;

install service

We provide customers with a full set of installation services such as site leveling, foundation drawing inspection, construction progress, team planning, installation guidance, and commissioning to ensure the smooth operation of the production line. In addition, we provide customers with appropriate training to achieve their satisfaction.

payment methods:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

Crushing and grinding machines are used to reduce the size of the shale particles and prepare them for further processing.

The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energy-saving capabilities, and ability to produce fine and ultrafine powders.

Calcium carbonate ultrafine grinding mill is an efficient industrial powder grinder machine. It can grind 100+ kinds of ores into fine powder.

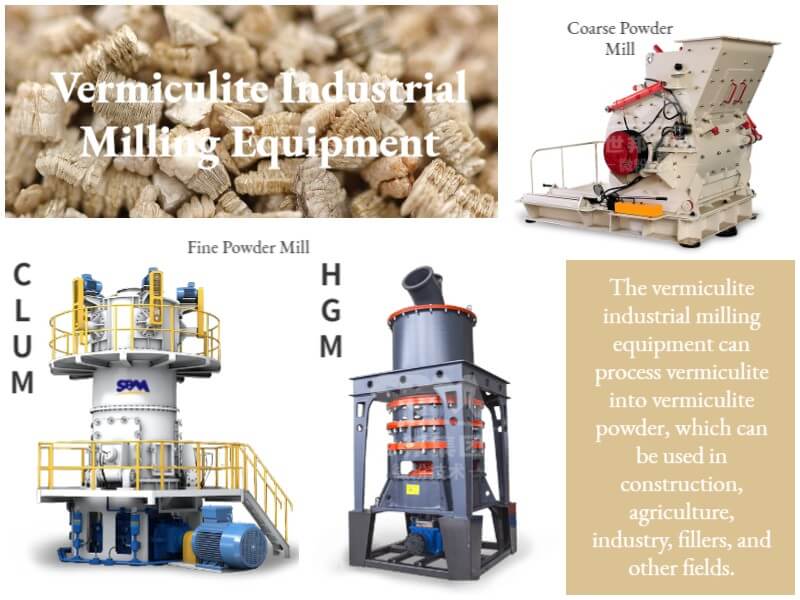

The vermiculite industrial milling equipment can process vermiculite into vermiculite powder, which can be used in construction, agriculture, industry, fillers, and other fields.

Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine mill, vertical mill, Raymond mill, wet mill, etc.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.