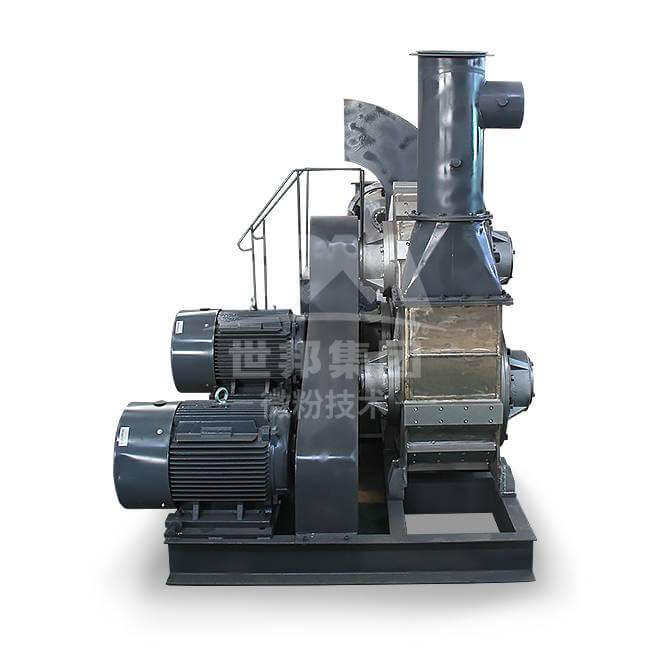

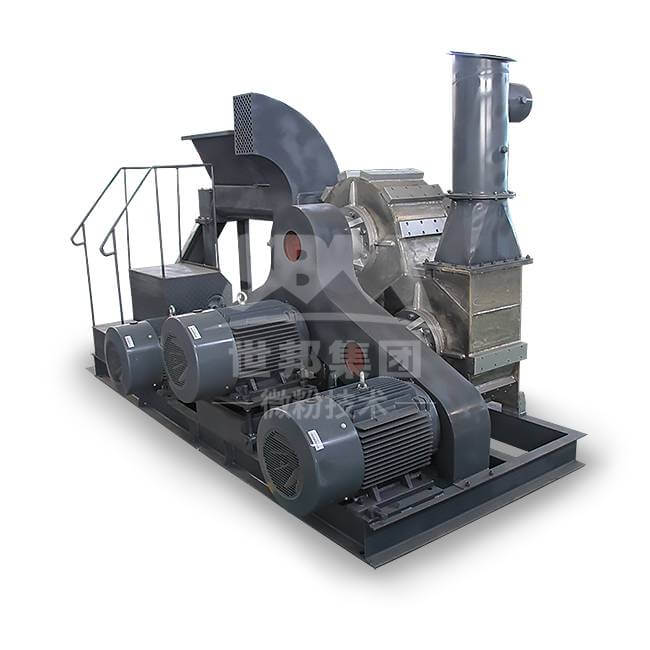

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

05/05/2022 admin

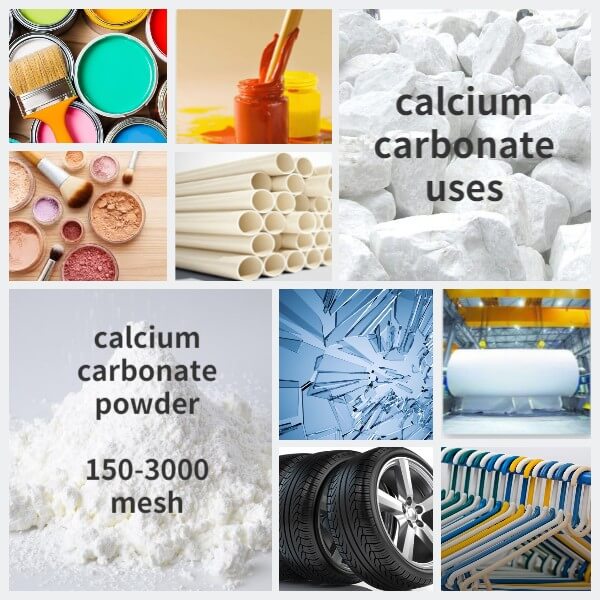

Calcium carbonate grinding mill is an efficient industrial ultrafine powder mill. It can grind calcium carbonate into fine and superfine powder(150-3000mesh). SBM is China’s famous calcium carbonate grinding mill manufacturer. Its self-developed HGM series ultrafine grinding mills and CLUM series ultrafine vertical roller mills are the most popular. They can both grind more than 100 kinds of non-metallic ore materials that include calcium carbonate.

Calcium carbonate (CaCO₃) is an inorganic compound, commonly known as limestone, limestone, stone powder, etc. It is alkaline, basically insoluble in water, but soluble in hydrochloric acid.

Calcium carbonate is one of the common substances on the earth. It exists in aragonite, calcite, chalk, limestone, marble, travertine, and other rocks. It is also the main component of some animal bones or shells.

Calcium carbonate is also important building material, and it has a wide range of industrial uses. It is used in papermaking, metallurgy, glass, alkali making, rubber, medicine, pigments, organic chemicals, and other sectors.

According to different production methods, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate, and crystalline calcium carbonate.

Heavy calcium carbonate is made by mechanical methods (using a fine powder mill or other industrial grinding mills) to directly crush natural calcite, limestone, chalk, shells, etc.

Light calcium carbonate is prepared by using limestone and other raw materials through a series of chemical reactions to obtain calcium carbonate precipitation, and finally through dehydration, drying, crushing, and grinding.

Common calcium carbonate production lines are inseparable from industrial grinding mill machines. After being ground into powder, calcium carbonate has a filling function. It is a good additive and is widely used.

Stage 1: broken

First use a jaw crusher to initially crush the large pieces of calcium carbonate, and then use a hammer crusher or a cone crusher to crush it to the fineness of the feed material (10mm-20mm) that can enter the mill.

Stage 2: grinding

The crushed small pieces of calcium carbonate are sent to the silo by elevator, and the vibrating feeder sends them to the grinding chamber of the mill evenly and quantitatively for grinding. For fine powder processing, SBM industrial calcium carbonate grinding mill is recommended.

Stage 3: powder classification

The ground calcium carbonate powder is classified by the classifier, and the unqualified powder is returned to the host for re-grinding.

Stage 4: collecting fans

The powder conforming to the fineness enters the dust collector with the airflow for separation and collection. Then it is sent to the finished product silo and then packed by a powder tanker or an automatic baler.

Most of the production process of calcium carbonate is inseparable from the milling process. Common calcium carbonate powders include 300 mesh, 400 mesh, 600 mesh, 800 mesh, 1200 mesh, 1500 mesh, and 2000 mesh. Their uses are more extensive.

The calcium carbonate ultrafine grinding mill developed and produced by SBM can meet the needs of calcium carbonate milling. The fineness of the finished product produced by the SBM ultrafine powder grinder machine can be freely adjusted between 150-3000 mesh. In addition to grinding calcium carbonate, it can also be used to grind more than 100 other non-metallic ores with Mohs hardness less than 6.

HGM series ultrafine grinding mills can be used to grind non-metallic ores with Mohs hardness less than 6.

HGM ultrafine powder mill has a material layer control structure, which can control the amount of feeder to avoid excessive belt load and prolong its service life.

The operation is simple, the maintenance is convenient, the oil can be added while working, and there is no need to shut down for maintenance.

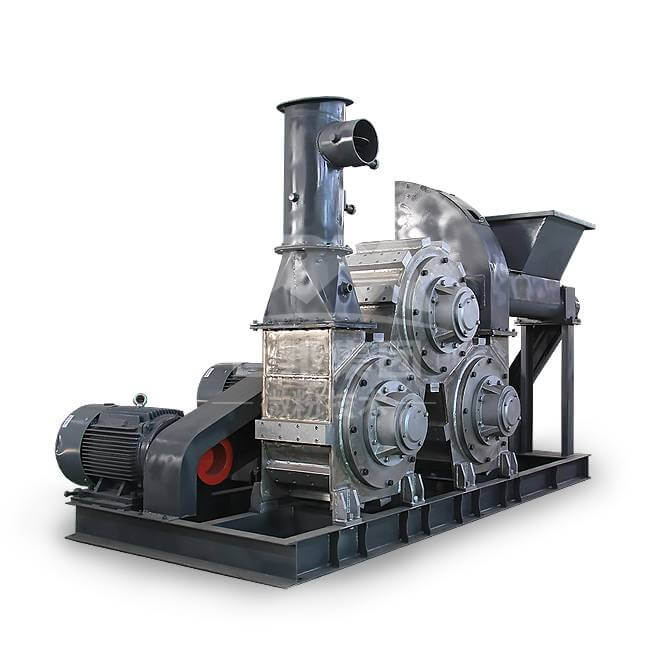

CLUM series ultrafine vertical roller mills can grind non-metallic ores with Mohs hardness less than 7, up to 3000 mesh.

Among the finished powders it grinds, the content of fine powder is higher, and the content of 2um is higher.

With secondary powder selection function.

The finished powder has high whiteness and good shape.

At present, it is especially popular in the field of high-end white powder production.

Model of grinding mill: HGM125L ultrafine grinding mill

Material: Calcium carbonate

Fineness: 300mesh

Capacity: 20ton per hour

Model of machine: CLUM1425 ultrafine vertical roller mill

Fineness: 800mesh, 1250-2500mesh

Material output: 300,000 tons/year

CLUM series ultrafine vertical roller mills have a large capacity, stable operation, low wear, long life, environmental protection and energy saving, simple operation, intelligent control system, easy maintenance, and the fineness can be freely adjusted between 150-3000 meshes.

The fineness of the calcium carbonate powder produced can reach 3000 meshes. The finished powder has high whiteness, good powder ball shape, high 2um fine powder content, and more fine powder content. It is a high-end powder without iron, especially suitable for high-end coatings, papermaking, and other fields.

Through the grinding of industrial grinding mills, the calcium carbonate powder specifications usually available are 200 mesh, 300 mesh, 400 mesh, 600 mesh, 800 mesh, 1250 mesh to 3000 mesh, and so on. It is widely used in many fields such as papermaking, rubber, cosmetics, building materials, paint, putty, coating, medicine, chemical industry, etc.

Superfine calcium carbonate can be used as a filler for high-end cosmetics, soaps, facial cleansers, children’s toothpaste, and other daily chemical products.

It can be used as an additive in the food industry. For example, it can be used in various feed additives.

In the coating industry, ultrafine calcium carbonate can be used as a whitening extender pigment to improve the gloss, drying, and hiding power of the paint and paint, and it also has a reinforcing effect.

The use of ultrafine calcium carbonate in papermaking not only reduces the cost but also improves the strength, whiteness, opacity, and smoothness of the paper.

Superfine calcium carbonate is used in ink products to show excellent dispersibility, transparency, excellent gloss, and hiding power, as well as excellent ink absorption and drying properties.

Calcium carbonate is widely used in filling polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), acrylonitrile-butadiene-styrene copolymer (ABS), and other resins.

Calcium carbonate can improve the processing performance of plastics, increase their heat resistance, improve astigmatism, scratch resistance, and smoothness of plastics

Rubber grade:

used for rubber packing and anti-sticking agent for rubber products.

The surface modification of calcium carbonate by powder modifier can improve the application performance of calcium carbonate, improve the applicability, and expand the market and dosage. In the future, functionalization and specialization will become the main trend in the development of calcium carbonate, and the product structure will also undergo great changes.

(1) Broaden application areas

Surface-modified calcium carbonate has better hydrophilic and lipophilic properties, reduced oil absorption, better dispersibility, coverage rate, and color. It is better used in high-end fields such as plastics, coatings, rubber, paper, sealants, and breathable membranes.

(2) Improve more functional properties of calcium carbonate powder

(3) Increase the added value of calcium carbonate products

(4) Development trend of calcium carbonate industry

When grinding calcium carbonate with SBM ultra-fine grinding mill machine, a powder modifier can also be added directly to mix and grind with the material. The finished powder after grinding is the modified powder. But the quality of powder modified by powder surface coating machines will be better.

SBM Powder Surface Coating Machine can realize the surface modification of calcium carbonate powder and improve the application performance of calcium carbonate. If there is a need for powder modification, our designers will directly configure the equipment in the production line plan.

About Us:

Shibang Industrial Technology Group Co., Ltd.(calcium carbonate grinding mill manufacturer) is an international enterprise group specializing in the research and development, production, sales, and service of equipment in the fields of mine crushing, construction crushing, tower sand making, and industrial milling. The company’s products are exported to more than 170 countries and regions around the world, with more than 30 overseas branches and business institutions, and its export value has ranked first in China’s mining machinery industry for ten consecutive years.

The world’s largest mining machine showroom

30+ years of development history

Quality first, customer first

IS09001:2000, CE, COST

Our Service:

Pre-sale

Help customers to select equipment

Free arrangement of engineers to the site for actual survey and plan design

On sale

Strictly implement the quality standards, and guarantee the quality of the ex-factory products

Free logistics and transportation information, more choices for logistics and transportation

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

After-sale

Free arrangements for engineers to guide the basic production of equipment

Provide free technical guidance for equipment installation and commissioning

The free on-site one-to-one operation, repair, maintenance, and other training

Professional after-sales service team, 24 hours response to customer needs

Payment methods we can accept:

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union

Single powder:

It is used to produce anhydrous calcium chloride (CaCl₂), which is an auxiliary raw material for the production of sodium dichromate. The main raw material for glass and cement production. In addition, it is also used in building materials and poultry feed.

Shuangfei powder:

It is used to produce raw materials such as anhydrous calcium chloride and glass, white fillers for rubber and paint, and building materials.

Three flying powder:

Used as a filler for plastics, paint putty, paint, plywood, and paint.

Four flying powder:

Used as a filler for wire insulation layer, rubber molded products, and filler for asphalt linoleum.

The commonly used specifications of calcium carbonate are 200 mesh, 300 mesh, 400 mesh, 600 mesh, 800 mesh, 1250 mesh to 3000 mesh, and so on. Different industrial grinding mills have different performances. As long as the most suitable mill is selected according to production requirements, it is the most cost-effective.

The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50-500 mesh. This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more environmentally friendly, and has a low investment.

150-3000 mesh calcium carbonate powder can use SBM calcium carbonate ultrafine grinding mill. They can produce ultra-fine powder, environmental protection, and energy-saving, convenient maintenance, stable operation, long service life, intelligent automation, simple and easy operation.

To learn more about industrial crushing and milling equipment, please feel free to consult us!

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.