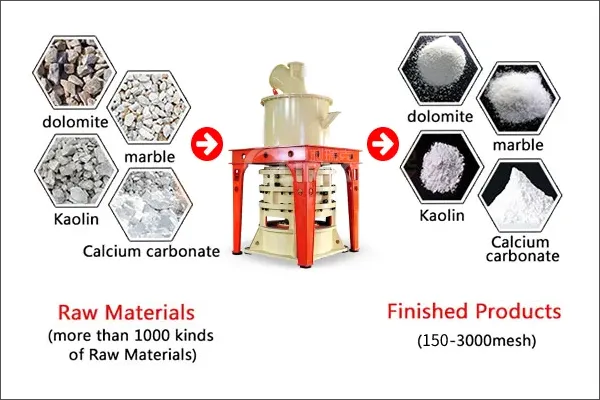

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

08/05/2024 admin

Montmorillonite powder, also known as bentonite clay powder, is a naturally occurring clay mineral composed primarily of hydrated sodium calcium aluminum silicate. It is derived from volcanic ash deposits and is known for its unique properties and wide range of applications.

Applications:

Industrial Uses: Montmorillonite powder is used in a wide range of industrial applications, including foundry sand binders, drilling muds in the oil and gas industry, and as a rheological additive in paints, adhesives, and coatings.

Environmental Remediation: It is utilized for soil stabilization, groundwater remediation, and wastewater treatment due to its adsorption and ion exchange capabilities.

Cosmetics and Personal Care: Montmorillonite powder is found in skincare products such as facial masks, cleansers, and bath products for its ability to absorb impurities and excess oil from the skin.

Pharmaceuticals: It is used as an excipient in pharmaceutical formulations and drug delivery systems due to its inertness, adsorption capacity, and ability to improve flow properties.

Animal Feed Additives: Montmorillonite powder is added to animal feed as a binder, anti-caking agent, and toxin binder to improve feed quality and animal health.

The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, energy-saving capabilities, and ability to produce fine and ultrafine powders.

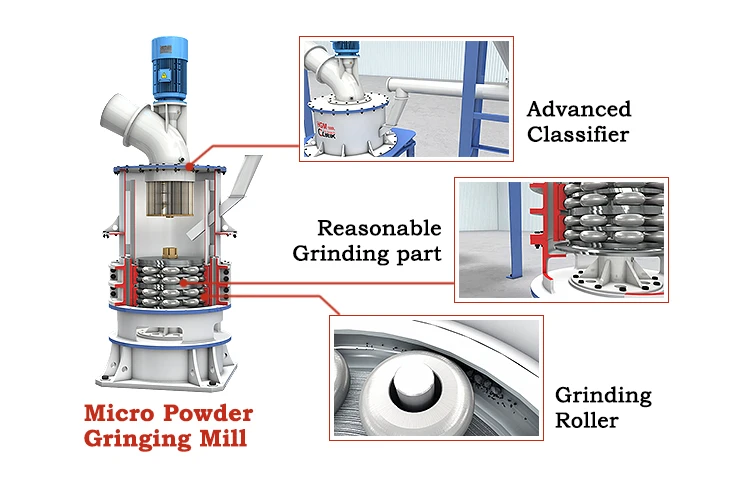

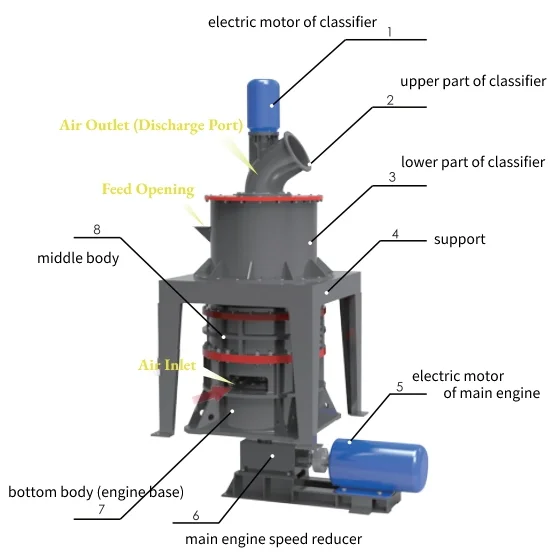

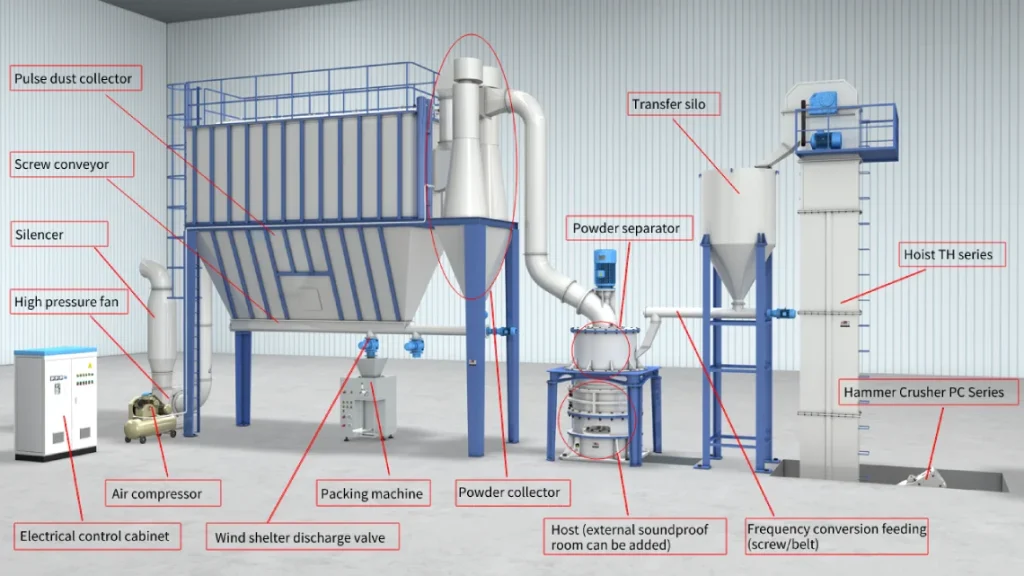

The HGM micro powder grinding mill has a complex yet well-engineered structure designed to facilitate efficient grinding and powder processing. Here’s an overview of its main components and structure:

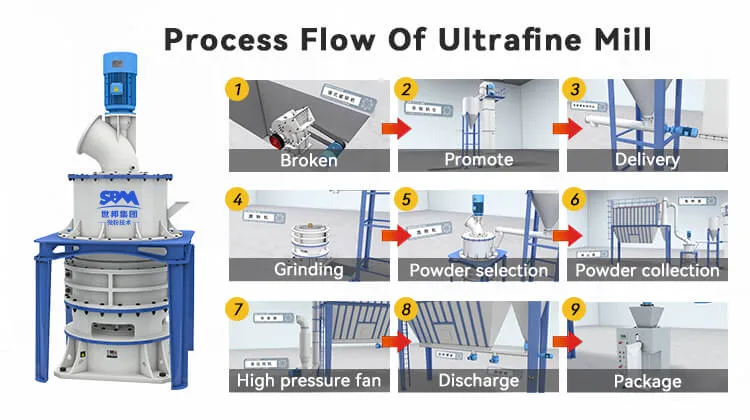

The HGM micro powder grinding mill processes montmorillonite through a series of steps that involve grinding, classification, and powder collection. Here’s an overview of how the HGM mill processes montmorillonite:

HGM micro powder grinding mill efficiently processes montmorillonite ore through a combination of grinding, classification, and powder collection, producing high-quality montmorillonite powder suitable for various industrial applications.

HGM micro powder grinding mill is well-suited for grinding montmorillonite and offers a reliable, efficient, and cost-effective solution for producing high-quality montmorillonite powder for various industrial applications.

Choosing the right stone powder grinding mill for your needs is crucial in achieving optimal…

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.