Raymond mill is a high-efficiency pulverizing mill that replaces ball mill to process ore powder.It has outstanding advantages such as strong systematicness, high screening rate, stable transmission, high wear resistance and convenient maintenance.

Discharge fineness: 80-600 mesh

Feed size: <35 mm

Output: 0.4-35 t/h

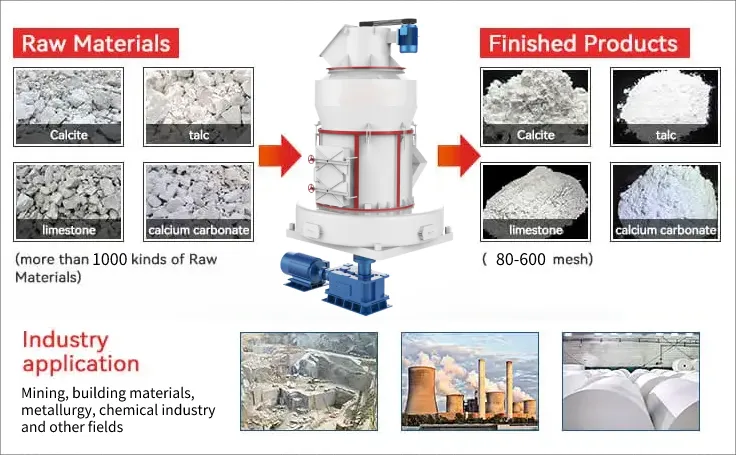

Materials: various non-flammable and explosive materials with Mohs hardness less than 9.3 and humidity less than 6%.

Product features: Flexible fineness adjustment, convenient operation and maintenance, advanced technology, high reliability, environmental protection and energy saving

Limestone Raymond Mill is an industrial superfine mill that grinds limestone into powder. It has a wide range of applications, including raw material processing in chemical industry, building materials, metallurgy, agriculture and other fields. The particle size range that can be produced is 80-500 mesh, which can be adjusted according to the requirements of different applications.

Limestone Raymond mill adopts the design of high grinding efficiency and low energy consumption, and adopts advanced technology to improve performance, including high-quality wear-resistant materials, precise and reliable pressure spring device, high-efficiency cyclone collector, etc.

Limestone is a widely used ore with several important uses, including the following:

Building materials: Limestone is an important raw material for making building materials, including lime, gypsum, cement, etc. Limestone can be fired to produce lime, which is widely used in construction, civil engineering and other construction fields.

Metallurgical industry: Limestone can be used as a flux and reducing agent in the metallurgical industry, which can be used to remove impurities in steel and improve the quality and purity of steel.

Environmental protection field: Limestone can be used to treat acid wastewater and waste gas and plays an important role in the field of environmental protection.

Chemical industry: Limestone can be used as a raw material for chemicals, pharmaceutical raw materials and fertilizers, and has a wide range of applications.

Food industry: Limestone can be used to adjust the acidity of food and increase the calcium content and is widely used in food processing.

Mineral processing: Limestone can be used to extract metal ores such as iron, copper, aluminum, etc.

In short, limestone has important application value in many fields and is a very important ore, so the processing of limestone is also very important.

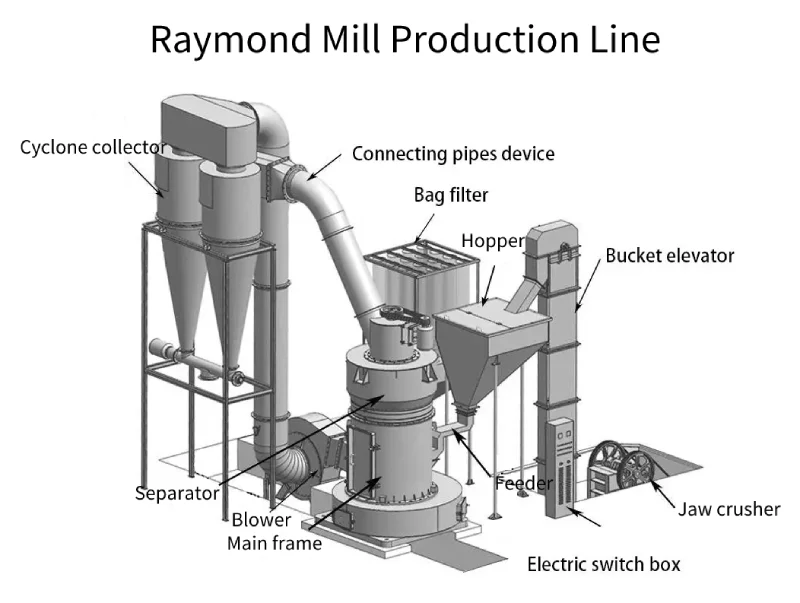

The general process of limestone processing with Raymond mill is as follows:

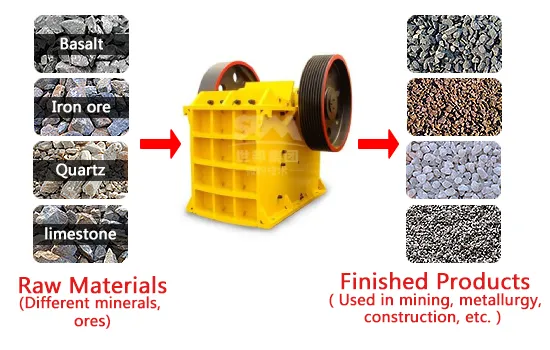

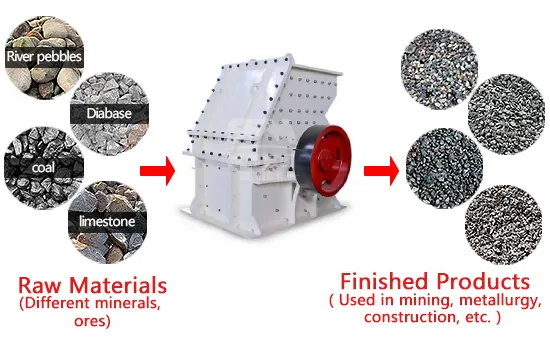

Crushing: Crushing limestone raw materials into small particles, usually using jaw crushers, hammer crushers and other equipment for coarse crushing.

Conveying: The crushed limestone particles are conveyed to the mill through a conveyor belt or a belt conveyor, usually using a vibrating feeder or a screw conveyor for conveying.

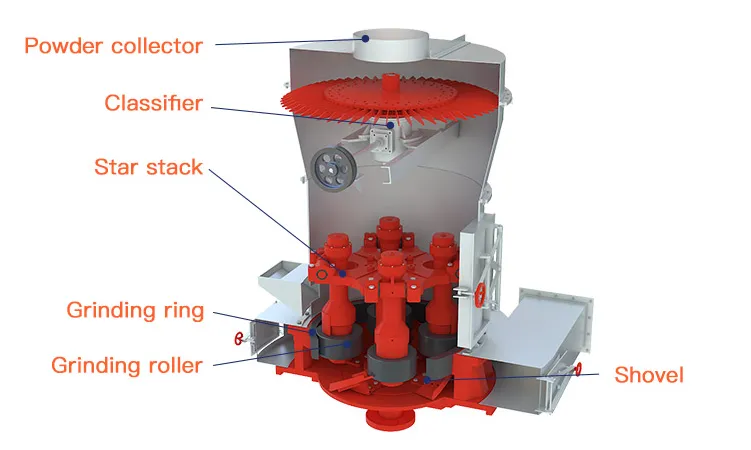

Grinding: The limestone particles are finely ground through a Raymond mill to obtain the desired fineness. The fineness of limestone can generally be controlled by adjusting the distance between the grinding roller and the grinding ring, the speed of the grinding roller and other parameters.

Classification: The milled limestone is classified by winnowing equipment to separate limestone powders with different particle sizes to meet different application requirements.

Collection: The graded limestone powder is collected by wind or mechanical collection devices.

Storage: Store the collected limestone powder for future use.

It should be noted that the process of limestone processing by Raymond mill will vary due to different production processes, process requirements, and raw material properties. Therefore, in the specific production process, it is necessary to make reasonable adjustments and optimizations according to the actual situation.

The main part of the limestone Raymond mill is mainly composed of the frame, the air inlet volute, the blade, the grinding roller, the grinding ring, the cover, and also includes the reducer, the analyzer, the fan, the finished product cyclone separator, and the dust collector. Equipment and air ducts and other components.

After the limestone is ground, the fan blows the wind into the main casing, blows up the powder, and is sorted by the analyzer placed above the grinding chamber, and the material that is too fine falls into the grinding chamber for regrinding, and the fineness meets the specification. Enter the cyclone collector with the wind flow, collect and discharge through the powder outlet, which is the finished product.

The air flow returns to the fan from the return air pipe at the upper end of the large cyclone collector. The air path is circular and flows under negative pressure. The excess air volume of the circulating air path is discharged through the exhaust pipe between the fan and the main engine and enters the small cyclone. Collector for purification.

● Wide range of applications: Limestone Raymond mills are widely used in various industries such as cement, building materials, power generation, metallurgy, and chemical industry. It can be used to grind various non-flammable and explosive materials with Mohs hardness less than 9.3 and humidity less than 6%.

● Flexible fineness adjustment: Limestone Raymond Mill can be adjusted in real time according to material properties, grinding fineness, production capacity and other requirements. High degree of automation, equipped with intelligent control system, to achieve precise control of the production process.

● High Reliability and Durability: The limestone Raymond mill is made of high-quality materials and components and is designed with a solid structure to ensure its high reliability and durability. Long service life, low maintenance costs, can effectively reduce production costs.

● Easy operation and maintenance: Limestone Raymond mill are easy to operate and easy to learn, and easy to maintain. Equipped with high-quality transmission device, the performance is stable and reliable.

● Advanced technology: Limestone Raymond mill adopts advanced technology to improve performance, including high-quality wear-resistant materials, precise and reliable pressure spring device, and high-efficiency cyclone collector.

● Low noise and vibration: Limestone Raymond mill adopt low noise and low vibration design, which can effectively reduce the impact on the environment and human body.

● Environmental protection: The limestone Raymond mill is designed with a dust removal system to effectively control dust emissions and reduce environmental pollution.

In general, limestone Raymond mill is an efficient and reliable industrial grinding equipment for grinding limestone into powder, which is widely used in various industries. With the continuous advancement of technology, the demand for high-quality limestone powder is increasing, and limestone Raymond mill will play an increasingly important role in the market.

| Model | Roller | Ring | Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

Fault 1: The main engine current rises, the temperature rises, and the fan current drops.

Reason analysis: Excessive feeding, the air duct is blocked by powder, the exhaust of the pipeline is not smooth, the heat of the circulating airflow makes the main current, the temperature of the machine rises, and the current of the fan decreases.

Solution: Clear the powder accumulated in the air duct and reduce the feeding. Open the valve of the large surplus air duct to control the temperature of the material entering the machine.

Fault 2: No powder or less powder

Reason analysis: The powder locker is not adjusted properly, and the seal is not tight, resulting in powder suction; the shovel blade wears a lot, and the material cannot be shoveled.

Solution: adjust the powder locker and pipeline; replace the blade.

Fault 3: The finished powder is too thick or too fine.

Reason analysis: the blades of the classifier are excessively worn, and the classification effect cannot be achieved; the air volume of the fan is improper.

Solution: Replace the fan blades; adjust the air volume.

Fault 4: fan vibration

Cause analysis: Dust accumulation on the fan blades or wear of the fan blades, resulting in insufficient balance; the anchor bolts are loose.

Solution: remove dust, replace blades; fasten anchor bolts.

Fault 5: The vibration and noise of the host are too loud.

Reason analysis: The feed rate is too small, or the shovel blade wears too much, the material cannot be shoveled, and the anchor bolts are loose; the hard material has a large impact, or there is no material layer; the grinding roller and grinding ring are too worn to cause loss of roundness.

Solution: adjust the feeding amount, check the blade, grinding roller and grinding ring, and replace them in time. Adjust feed particle size.

Fault 6: Abnormal sound of the host, excessive current and vibration

Cause analysis: Foreign matter enters the grinding chamber and damages the moving parts; the oil seal of the grinding roller is damaged, causing the bearing to be stuck due to ash entering or the bearing is burned due to insufficient lubrication; the central shaft bearing is damaged, etc.

Solution: Stop the machine and carefully check whether there is any foreign matter in the grinding chamber; check the central shaft bearing and grinding roller bearing and replace the oil seal and bearing.

Fault 7: The transmission device and the analysis engine oil tank heat up.

Reason analysis: The viscosity of the engine oil is high, and the oil is thick, and the thread pump oil cannot be pumped, so that the upper bearing is short of oil.

Solution: Check whether the grade and viscosity of the engine oil meet the requirements.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.