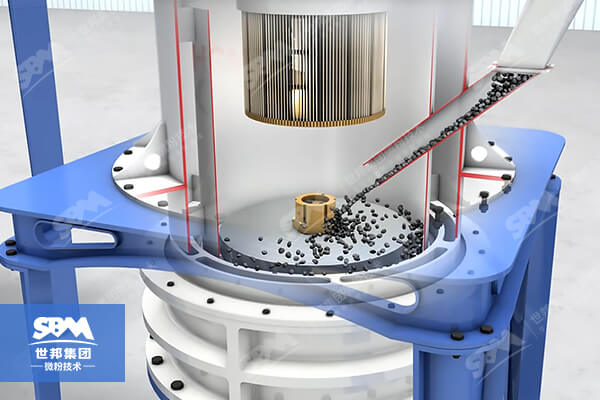

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 150-3000 mesh

Feed size.: <20 mm

Output: 0.5-45 T/H

Product features: The milling equipment has stable operation, high production efficiency, simple operation, convenient maintenance, safety, and environmental protection. It is a very popular industrial ultrafine milling equipment.

The marble powder making machine can grind broken marble blocks into marble powder. The main component of marble is calcium carbonate like calcite, and the calcium carbonate component of marble accounts for more than 50%. Marble powder can be used in industry, rubber, chemical, and other fields.

The marble powder making machine produced by SBM can also process non-metallic minerals (talc, barite, gypsum, dolomite, diatomaceous earth, rice stone, etc.), bamboo, shells, coconut shells, eggshells, glass, etc. The milling equipment has stable operation, high production efficiency, simple operation, convenient maintenance, safety, and environmental protection. It is a very popular industrial ultrafine milling equipment.

Powder Fineness Process Ability: 150-3000 mesh

Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0.5-45 t/h

Use Range: can be used in more than 300 kinds of stone materials powder grinding, such as calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble, and so on

Application: mining, chemical, transport, and many other different areas

Marble is a non-metallic mineral material. It has the advantages of high environmental protection, high colloid, high viscosity, and high hardness.

With the continuous increase of scientific and technological research on this resource, its comprehensive utilization value and scope of use have been significantly improved. It is widely used in industry, chemical industry, machinery, metallurgy, plastics, and other fields.

Marble powder can be used as a filler in cement or as a fine aggregate in the preparation of concrete. Marble powder can be used as an admixture for concrete to increase the strength of concrete.

The first stage: the crushed large pieces of marble are transported by special vehicles to the raw material warehouse, and then the materials are sent to the jaw crusher by forklifts/manually for crushing and crushed to be smaller than the feed size of the mill.

The second stage: the marble after the feed is crushed by the crusher is lifted by the elevator to the storage hopper, and the storage hopper is discharged and then fed to the host by the feeder evenly.

The third stage: the qualified products in the grinding and grinding process are screened by the screening system and then enter the collector through the pipeline. After being collected, they are discharged through the powder pipe to become the finished product, and the unqualified products fall into the main machine and re-grind.

The fourth stage: the purified airflow of the finished product flows into the blower through the residual air pipe above the dust collector. The air path is circular. Except for the positive pressure from the blower to the grinding chamber, the airflow in the other pipelines flows under negative pressure, and the indoor sanitary conditions are good.

① The structure design is novel, the structure layout is simple and reasonable, and the three-dimensional structure is adopted. The integrated design of powder and powder selection not only saves floor space but also reduces input costs.

② The use of mature production technology and processing technology makes the operating state of the equipment very stable, which plays an important role in improving the production efficiency of the equipment.

③ Multi-layer grinding ring design, higher grinding efficiency.

④ Wide grinding range. Adjustable particle size: 150-3000 mesh.

⑤ The wearing parts are made of wear-resistant materials. The high utilization rate of wear-resistant materials: 2-5 years.

⑥ The structure is firm and reliable. The design of the mill is rigorous and will not damage the machine due to loose screws.

⑦ The intelligent control system makes the operation easier and saves labor.

⑧ In-depth research on the dust-proof device system, the whole machine has good airtightness and low dust overflow rate, which can effectively improve the working environment.

Ultrafine grinding mill is an industrial device used to grind solid materials, like mica, limestone, calcite, etc.

Model: HGM

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.