The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Capacity: 1.5-45 t/h

Range of application: calcium carbonate, kaolin, quartz, talc, mica, etc.

Product features: calcium carbonate, kaolin, quartz, talc, mica, etc.

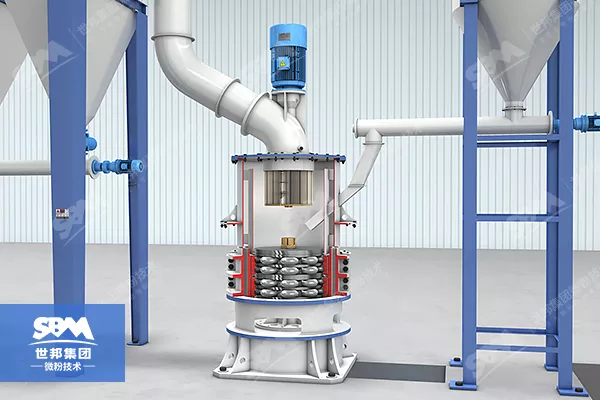

The CDF multi-head classifier cooperates with different kinds of grinding mills.

In the grinding process of calcite, mica, gypsum, barite, kaolin, talc, limestone, silica, Mg/AL(OH)3, carbon black, metal powder, wood powder, and other materials, the powder is accurately classified.

The final product is widely used in plastic, rubber, painting, food, abrasives, ceramics, new materials, and other industries.

From the bottom-feeding inlet, the materials are sent to the separating field by inhaling of air blower.

Coarse and fine materials are separated by the powerful centrifugal force generated by a high-speed rotating classifying turbine.

The qualified fine powders are sent into a cyclone separator or dust cleaner to be collected by a classifier blade.

The unqualified coarse powder with little fine powders hit the classifier surface, fall down to the grinding chamber, and reground.

1. High rotated speed and accurate vertex cutting. According to the hydromechanics principle, optimize the structure and the gag between the impeller.

2. High Capacity and low consumption. The max capacity can be reached 50 t/h, and the electricity consumption is much lower than the traditional classifier.

3. PLC automatic control system, running real-time display, easy to operate.

4. Horizontal classifying turbine unit with high speed and accurate vertex cutting.

| Model | CDF/3 | CDF/4 | CDF/5 |

| Powder(kw) | 3*11 | 4*15 | 5*18.5 |

| Max Speed(rpm) | 3500 | 3000 | 3000 |

| Fineness(um) | 5-150 | 6-150 | 8-150 |

| Capacity(t/h) | 1.5-10 | 2.8-20 | 5-45 |

1. Industrial grinding

Grinding particle size: covering 0-3 mm coarse powder; 20-400 mesh fine powder; 400-3250 mesh superfine powder.

2. Industrial crushing

Crushing field: various soft, medium, and hard ores.

Coarse crushing/medium crushing/fine crushing, sand-making, sand-washing, feeding, screening, conveying, etc.

3. Various ores

Application: various soft, medium, and hard non-metal ores crushing, conveying, grinding, powder selection, powder collection, dust removal, packaging, etc.

4. Building materials

Building crushing: crushing and screening of various rocks, construction waste, and industrial solid waste. Provide overall solutions for building materials, roads, railways, hydropower and other infrastructure fields.

Building materials field: Provide green, environmentally friendly, efficient and advanced supporting equipment and solutions. High quality and high efficiency, environmental protection and energy saving, high investment value.

The HGM Stone Mill Grinder, also known as the HGM series ultrafine powder grinder mill, is a highly advanced and efficient grinding machine designed to produce fine and superfine powders from a wide range of non-inflammable, non-explosive, and brittle materials with a Mohs hardness under 6. This versatile equipment has gained significant popularity in various industrial…

In the realm of industrial mineral processing, the demand for robust, high-output rock pulverizer machines has never been greater. Among the most advanced solutions in this field is the HGM series of ultrafine grinding mills, engineered to deliver precision, durability, and scalability for large-scale operations. This article delves into the flagship HGM125 model and its…

A ring mill, also known as a ring roller mill, micro powder grinding mill, or ultrafine grinding mill, is a type of grinding equipment commonly used in the industrial production of ultrafine calcium carbonate.

The CLQM series Airflow Vortex Mill Powder Micronizer is designed for processing a wide range of materials, offering uniform particle sizes that can be adjusted according to specific requirements. The CLQM airflow vortex mill powder micronizer is capable of grinding materials to micron and sub-micron levels, making it highly versatile and suitable for processing difficult-to-handle…

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultra-fine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying.

Ultrafine vertical mill is a high-efficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc

Capacity: 1.5-45 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.