The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

28/02/2023 admin

Witherite, also known as barium carbonate ore, has the chemical formula BaCO3 and belongs to silicate minerals. The color is colorless or slightly gray to light yellow. Vitreous luster, hardness 3-3.5, density 4.2-4.3. Commonly found in hydrothermal mines, it is symbiotic with calcite, barite, fisheye and so on. It is used to extract barium and prepare barium compounds, mainly used in glass, enamel, glaze, pigment, leather and other manufacturing industries.

Witherite is another main barium-containing mineral in nature besides barite. It has the characteristics of large specific weight, low hardness, and absorption of X-rays and γ-rays. It is widely used in oil and gas drilling, chemical industry, light industry, metallurgy, building materials, medicine and other industrial sectors, especially high-quality barium raw materials in the manufacture of chemical products.

The processing of barium carbonate usually requires the use of milling equipment to crush it to the required fineness. Common milling equipment includes ball mills, vertical mills, high-pressure suspension roller mills, etc.

Specific uses include:

Industrial use: Barium carbonate ore is an important industrial raw material, widely used in chemical industry, building materials, electronics, pharmaceuticals and other fields. By processing barium carbonate ore with grinding equipment, the required powder can be obtained, which is convenient for subsequent processing and production.

Medical use: Barium carbonate has many applications in the medical field, such as X-ray contrast agent, treatment of peptic ulcer, etc. The barium carbonate ore is ground into powder by grinding equipment, which can facilitate the preparation and use for medical purposes.

Environmental protection use: barium carbonate can be used as a water purifier to purify harmful substances such as heavy metal ions in wastewater. Grinding barium carbonate ore into powder by grinding equipment can increase its surface area and activity and improve the purification effect.

In short, grinding equipment is one of the important equipment for barium carbonate ore processing, which has a wide range of uses and can meet the needs of different fields.

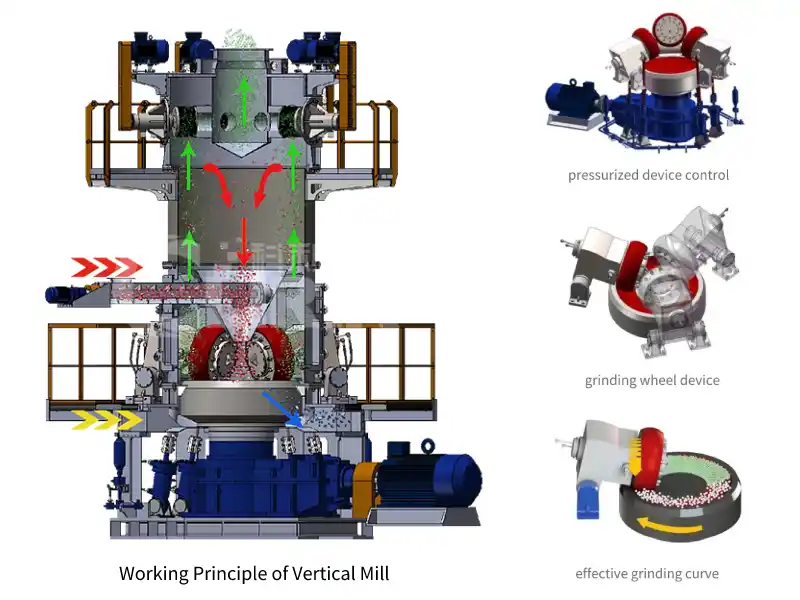

Barium carbonate ore vertical mill is a commonly used grinding equipment, mainly used for processing barium carbonate ore and other ores, non-metallic minerals, building materials and other materials. The following introduces its advantages, performance and other aspects:

CLUM vertical roller mill

Discharge fineness: 150-3000 mesh

Feed size: <20 mm

Output: 1-20 T/H

● Efficient: The vertical mill adopts a vertical structure, and the material is ground multiple times between the grinding disc and the grinding roller. The grinding efficiency is high, and the production efficiency can be greatly improved.

● Adjustable fineness: The grinding disc and grinding roller of the vertical mill can adjust the speed and grinding pressure by adjusting the clutch and transmission, so as to obtain products with different fineness.

● Good stability: The grinding roller of the vertical mill is made of high-strength alloy material, which has good wear resistance and impact resistance, can run stably for a long time, and improves the service life of the equipment.

● Small footprint: The volume of the vertical mill is relatively small, and the floor space is also relatively small, and the requirements for the construction of the factory building are low.

● High grinding efficiency: The vertical mill adopts high-speed rotating grinding disc and grinding roller, and the material is subjected to multiple impacts and frictions between the two, which can quickly grind the material and improve the grinding efficiency.

● Controllable crushing fineness: By adjusting parameters such as speed and grinding pressure, the crushing fineness of the product can be controlled to meet the needs of different fields.

● High degree of automation: The vertical mill adopts an automatic control system, which can automatically control parameters such as grinding pressure and speed, improve production efficiency and reduce operation difficulty.

In short, the barium carbonate ore vertical mill has the advantages of high efficiency, stability, and controllable crushing fineness, and is suitable for the crushing and processing of barium carbonate ore and other materials.

The witherite crushing and grinding production line generally includes crushing, conveying, grinding, conveying and finished product packaging. The specific process is as follows:

① Ore crushing: The raw ore is broken into smaller particles by crushing equipment for subsequent processing and production.

② Ore conveying: the crushed ore is transported to the feeding port of the grinding equipment through the conveying equipment.

③ Ore grinding: use grinding equipment to grind the ore to the required fineness. Commonly used milling equipment includes ball mills, vertical mills, high-pressure suspension roller mills, etc.

④ Powder conveying: The powder produced by the milling equipment is transported to the finished product packaging area through the conveying equipment.

⑤ Finished product packaging: The powder delivered to the finished product packaging area is packaged, and the common packaging methods include bags, barrels, etc.

In the milling process, in order to improve production efficiency and reduce energy consumption, some auxiliary equipment can also be added, such as vibrating screen, dust collector, air classifier, etc.

The above is the basic process of the non-metallic ore crushing and grinding production line. The specific production line design and selection need to be adjusted and optimized according to different raw materials and production requirements.

CLUM ultra-fine vertical mill is independently developed and produced by SBM micro-powder technology. Our vertical mill production line integrates crushing, grinding, transportation, grading, packaging and other functions. The specific production line design and selection need to be adjusted and optimized according to different raw materials and production requirements. Our professional technicians can provide you with production line design and configuration solutions.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.