The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Discharge fineness: 325-2500 mesh

Feed size: <20mm

Output: 0.5-45 t/h

Product features: Stable operation, simple operation, long service life, environmental protection, and maintenance without stopping the machine.

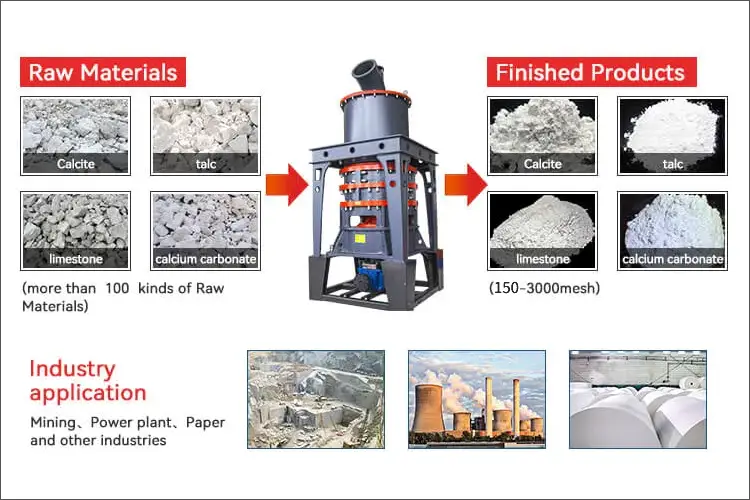

HGM90 Ultra Fine Grinding Mill is mainly applied to non-inflammable, non-explosive and brittle materials with Mohs hardness under six. Such as calcite, chalk, limestone, dolomite, kaolin, gypsum, etc, totally more than 100 kinds of materials. Product fineness can be controlled between 325~2500 mesh.

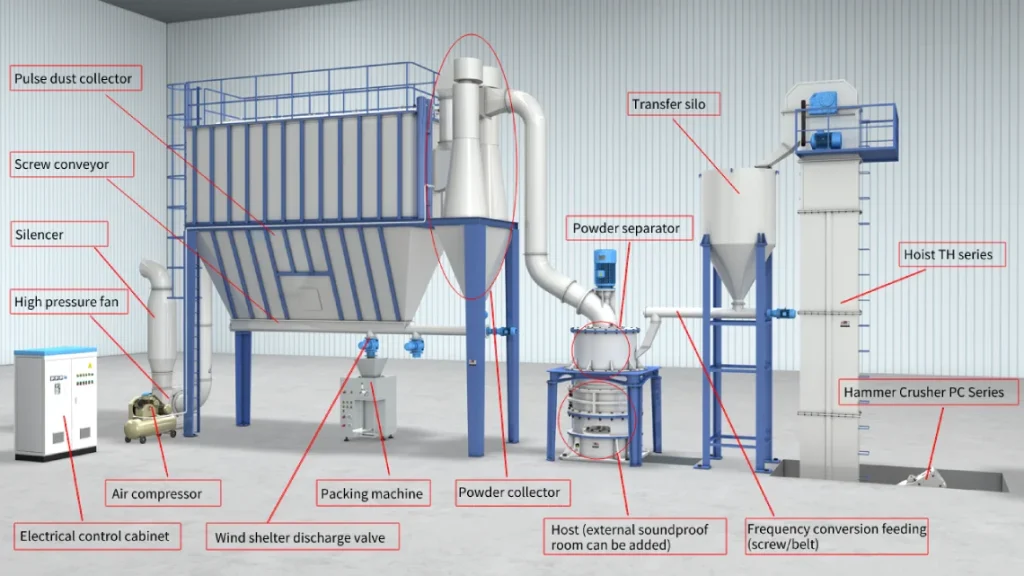

HGM90 Ultra Fine Grinding Mill main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial through plunger. After crushed by hammer crusher, the big materials become small ones and are sent to storage hopper by elevator and further sent to the middle of first dial evenly by the electromagnetic vibrating feeder and feeding pipe. The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings. The high pressure centrifugal blower will inhale air from outside and blow the crushed materials to classifier. The rotating turbo in the powder concentrator will make the coarse materials return to the mill and reground, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it. The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

1. High efficiency

Under the same final size and power, the product capacity of HGM90 Ultra Fine Grinding Mill is twice than jet mill and agitation mill.

2. Longer lifetime of spare parts

The roller and ring are made of special material, which improve the grinding efficiency a lot. For same material and final size, the lifetime of its wearing parts can reach to more than one year, about 2-5 times as long as that of vertical shaft impact crusher and turbo-mill. Especially when handling calcium carbonate and calcite, the lifetime can reach 2-5 years.

3. High safety and reliability:

There are no rolling bearings and bolts in grinding cavity, so problems caused by bolts shedding or wear of bearings and seal components will never happen.

4. High fineness of products

The product fineness can reach D97≤5μm.

5. Environment friendly

The application of pulse dust collector and muffler reduce the pollution and noise of the dust, which has reached national environment protection standard.

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Shibang Micro Powder Technology Co., Ltd. is an excellent ore grinding equipment manufacturer integrating R&D, production, sales and service. It has made great achievements in the field of ultra-fine grinding.

We promise to provide the best service to every customer. Our service promise is not a slogan, an idea or an advertisement. Our service commitment is serious. To this end, we have built a large, systematic and standardized service guarantee system to ensure that every link is implemented in place and processed accurately.

SBM takes the advice of its clients very seriously. We have established an after-sales return visit team of more than 100 people. On the one hand, we solve problems encountered by customer projects in a timely manner; on the other hand, we collect customer feedback and improvement opinions to provide better development directions for equipment research and development.

Turn on the Internet of Things mode and regularly assist users with testing, debugging and technical guidance. Full life cycle services to solve the embarrassing situation where no one cares about the problems after the customer’s project is completed

Model: HGM90

Capacity: 0.8-6.5t/h

Max feeding size: 10 mm

Processing ability: 0.8-6.5 t/h

Finished size: 325~2500 meshes(5-45 micron)

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.