The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

26/03/2024 admin

Calcium carbonate is an important industrial raw material with a wide range of applications. With the development of economy, the demand for calcium carbonate will continue to grow. Therefore, the establishment of a calcium carbonate ultrafine grinding production line has broad market prospects. The following are some suggestions for building a calcium carbonate ultrafine grinding production line:

1. Market research

First of all, you need to conduct market research to understand the market demand for 2500 mesh calcium carbonate ultrafine powder, including demand, price, quality requirements, etc. This will help you determine the size of your production line and product positioning.

2. Raw material analysis

You need to analyze your calcium carbonate mineral resources to understand their chemical composition, physical properties, etc. This will help you choose the right grinding process and equipment.

3. Process design

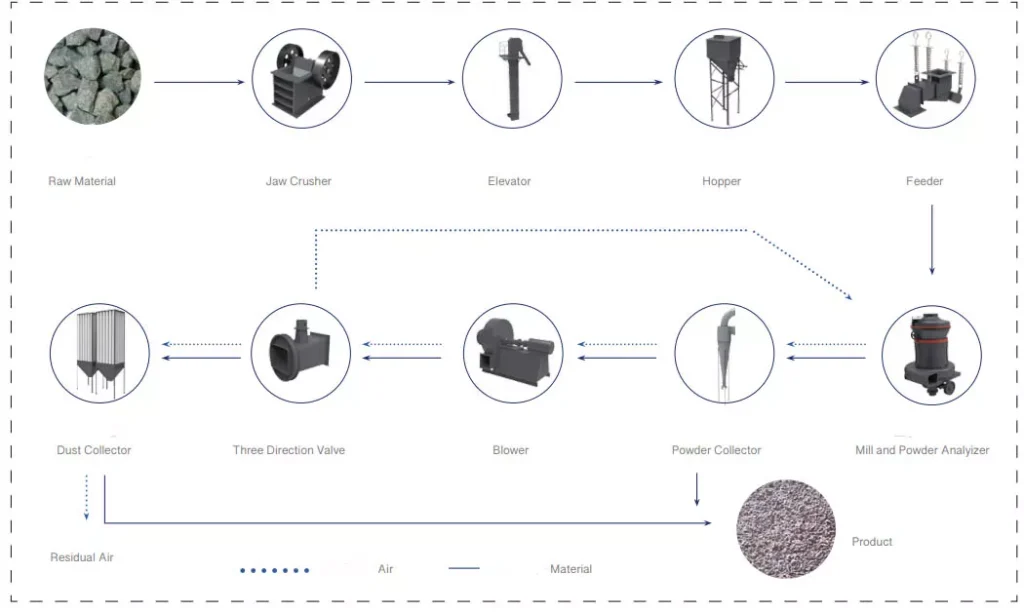

Based on the results of market research and raw material analysis, you can design the process flow of your production line. Generally speaking, the ultra-fine grinding production line includes the following links:

Crushing: Crush raw ore into a certain particle size for easy grinding.

Grinding: Grind the crushed materials into ultra-fine powder.

Classification: Classify the ground materials and screen out ultra-fine powder that meets the requirements.

Dust removal: Collect dust generated during the grinding process to prevent environmental pollution.

Packaging: Pack the qualified ultrafine powder for easy transportation and storage.

4. Equipment selection

Depending on your needs, you will need the following equipment:

Crusher: According to the hardness and particle size requirements of the raw ore, select the appropriate crusher, such as jaw crusher, impact crusher, cone crusher, etc.

Ultra-fine mill: Currently commonly used ultra-fine mills include Raymond mill, high-pressure mill, ring roller mill, ultra-fine vertical mill, etc. You can choose a suitable mill based on your output, fineness requirements and investment budget.

Classifier: Commonly used classifiers include high-pressure classifiers, cyclone classifiers, sedimentation classifiers, etc. You can choose a suitable grader based on your fineness requirements and output.

Dust collector: Commonly used dust collectors include bag dust collectors, electrostatic precipitators, cyclone dust collectors, etc. You can choose a suitable dust collector based on your dust emissions and environmental requirements.

Packaging Machine: You can choose a suitable packaging machine based on your output and packaging requirements.

5. Production line design

When designing your production line, you need to consider the following factors:

Output: You need to determine the output of your production line based on your market demand and production capacity.

Fineness: You need to determine the fineness requirements of your product based on your product application field and customer needs.

Investment budget: You need to determine the investment budget for the production line based on your financial strength.

6. Investment budget

The investment budget for establishing a calcium carbonate ultrafine grinding production line mainly includes the following items:

Equipment investment: Equipment investment is the largest investment item, accounting for approximately 70%-80% of the total investment.

Factory construction investment: Factory construction investment accounts for approximately 10%-20% of the total investment.

Personnel costs: Personnel costs account for approximately 5%-10% of the total investment.

Other expenses: Other expenses include raw materials, water and electricity fees, maintenance fees, etc., accounting for approximately 5%-10% of the total investment.

7. Other precautions

Site selection: You need to choose a suitable site to build the production line. The site should have good transportation conditions, water and electricity supply, and environmental protection facilities.

People: You need professional staff to operate and maintain your production line.

Environmental protection: You need to take necessary measures to prevent the production line from causing pollution to the environment. Such as installing dust collectors, spraying dust suppression, etc.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.