The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

19/03/2024 admin

To process light-burned magnesium oxide into 1500-mesh fine powder, you need to configure the following equipment:

Crushing equipment: crush the raw magnesite into particles smaller than 20mm to facilitate subsequent processing. Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etc.

Grinding equipment: Grind the crushed raw materials into fine powder. Commonly used grinding equipment include ball mills, Raymond mills, ultra-fine grinding mills, etc.

Classification equipment: Classify the ground fine powder according to particle size, and sift out 1500-mesh fine powder. Commonly used classification equipment includes vibrating screens, air classifiers, cyclone classifiers, etc.

Dust removal equipment: Collect dust generated during the production process to avoid environmental pollution. Commonly used dust removal equipment includes bag dust collectors, electrostatic precipitators, cyclone dust collectors, etc.

Packaging equipment: Pack qualified finished products into bags for easy transportation and storage. Commonly used packaging equipment includes automatic packaging machines, semi-automatic packaging machines, manual packaging machines, etc.

Electrical control system: used to control the operation of the entire production line. PLC control system is optional.

1. High production efficiency: Using advanced production technology and equipment, the production efficiency is high and the output is large.

2. Good product quality: The product has uniform particle size, with a fineness of up to 1500 mesh, and the quality meets national standards.

3. Low energy consumption: Using energy-saving equipment, production energy consumption is low and the cost is low.

4. Environmental protection: It adopts a closed production process and is equipped with a dust collector to prevent dust from polluting the environment.

5. High degree of automation: It adopts electrical control system to realize automated production and simple operation.

Crusher: It is recommended to use jaw crusher or impact crusher.

Pulverizer: It is recommended to use ring roller mill or ultra-fine vertical mill.

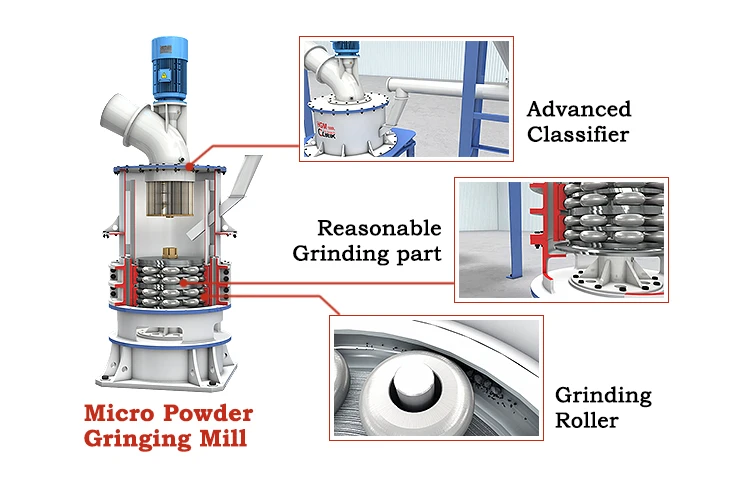

● Ultra-fine ring roller mill

Ultra-fine ring roller mill is a new type of ultra-fine grinding equipment, which has the advantages of large output, high efficiency, uniform fineness, and low energy consumption. The machine consists of roller table, grinding ring, frame, transmission device, etc. The roller table consists of multiple rollers with annular grinding teeth on the surface. The grinding ring is fixed on the frame, and the inner wall of the grinding ring also has annular grinding teeth. The material is crushed through the gap between the roller table and the grinding ring.

The powder output fineness of the ultra-fine ring roller mill can be adjusted between 325 mesh and 2500 mesh according to needs, and the product fineness can reach 5um at one time. This machine is suitable for grinding magnesium oxide, calcium carbonate, limestone, kaolin, fluorite and other non-metallic mineral materials.

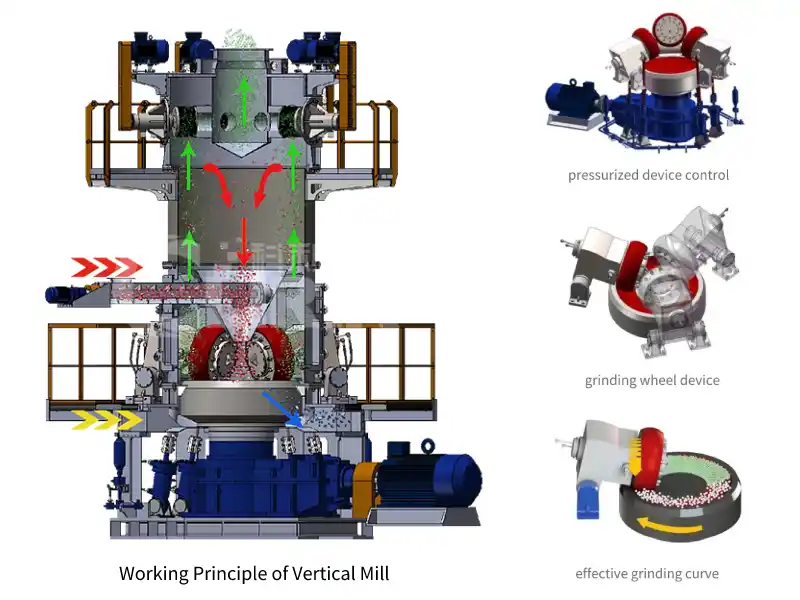

● Vertical grinding mill

Vertical mill is a new type of ultra-fine grinding equipment, which has the advantages of small footprint, compact structure and easy operation. The machine consists of a frame, spindle, grinding disc, grinding roller, separator, etc. The rotation of the main shaft drives the grinding disc and grinding roller to crush the material.

The powder output fineness of the vertical mill can be adjusted between 325 mesh and 2500 mesh as needed, and the product fineness can reach 3um at one time. This machine is suitable for grinding magnesium oxide, calcium carbonate, limestone, kaolin, fluorite and other non-metallic mineral materials.

● Air flow mill

Air flow mill is an ultra-fine grinding equipment that uses high-speed airflow to crush materials. The working principle of the airflow mill is: the material enters the grinding chamber through the feed port and is crushed under the action of high-speed airflow. The powder fineness of the airflow mill can be controlled by adjusting the speed and flow rate of the airflow, and can generally be less than 1 micron.

Classifier: It is recommended to use a vibrating screen or air classifier.

Dust collector: It is recommended to use bag dust collector or pulse dust collector.

Conveyor: It is recommended to use belt conveyor or screw conveyor.

Packaging machine: It is recommended to use an automatic packaging machine.

Electrical control system: It is recommended to use PLC control system.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.