The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

27/11/2023 admin

As one of the most widely used crushing equipment, the maintenance and repair of cone crushers are also issues that users are more concerned about. Regular maintenance can detect problems in advance and prevent problems before they occur. It also helps to extend the service life of cone crushers. General maintenance is divided into minor maintenance, medium maintenance and overhaul. The specific time intervals and inspection components are as follows:

Minor repairs

Minor repairs are usually carried out once every half a month to a month, and their contents include:

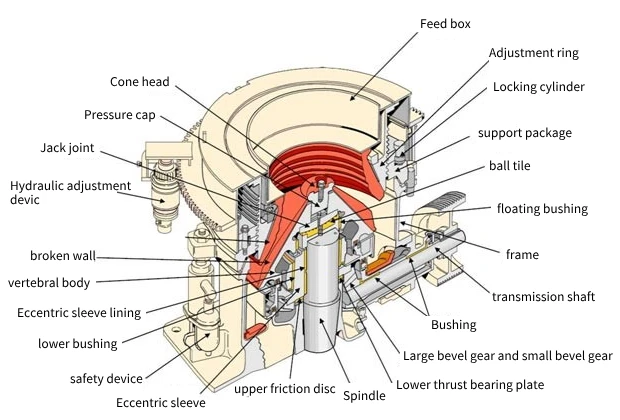

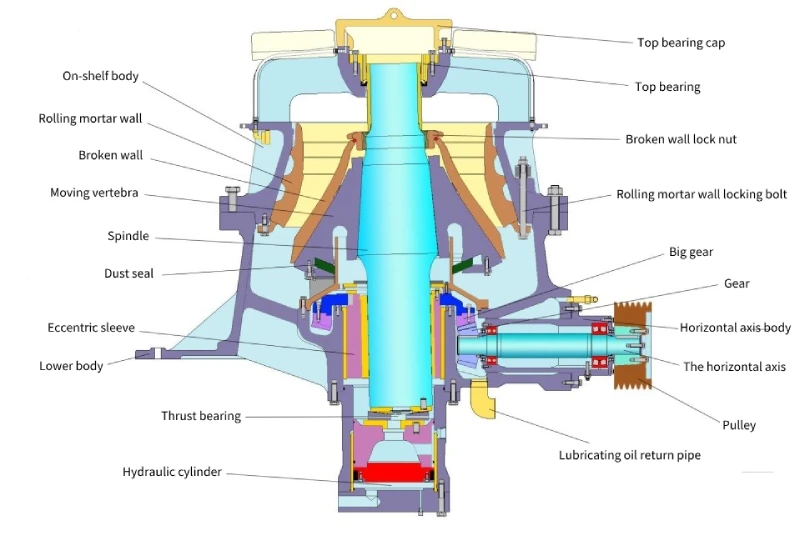

1) Check the wear of spherical bearings, tapered sleeves, eccentric sleeves, base bushings, bottom bearings, bevel gears, dustproof and sealing devices and adjust their coordination;

2) Partially replace or adjust the base spring;

3) Tighten all bolts;

4) Clean and inspect the oil circuit, cooling and dust-proof water system, eliminate oil leakage, add or replace lubricating oil, and repair the oil pump;

5) Check the wear of the umbrella board and various protective plates;

6) Check the clearance and movement of the transmission bearing (sleeve) and replace if necessary;

7) Clean and refuel the motor bearings.

Intermediate repair

Intermediate repair is usually performed once every 4 to 6 months, and its main contents include:

1) Replace the lining;

2) Repair or replace eccentric sleeves, tapered sleeves and straight sleeves;

3) Repair or replace bowl-shaped tiles and dust-proof devices;

4) Repair or replace bevel gears, drive shafts and bearings;

5) Repair the threads of the adjustment ring and support sleeve;

6) Inspect and handle all minor repair projects;

7) Disassemble the motor, blow dust and remove scale, and check the bearing clearance of each part; disassemble the oil switch, clean and deal with defects; adjust and test the electrical of each part; inspect and repair the switchboard and other cables, etc.

Large scale maintenance

Large-scale maintenance depends on the situation, usually once every 3-4 years, depending on the production situation. The main contents include:

1) Disassemble the entire cone crusher for inspection, adjust the gear meshing clearance, and check or replace the upper, middle and lower discs;

2) Replace the movable and fixed linings;

3) Replace the tapered sleeve, base bushing, large and small bevel gears, drive shaft, etc.;

4) Scrape the spherical bearing or replace or weld the spherical bearing seat;

5) Welding supply funnels, protective covers, body guards, etc.;

6) Replace some or all of the machine base springs and spring bolts;

7) Replace the oil pump.

The frequency of minor repairs is relatively high, and users can extend it to 1-2 months during production according to specific circumstances. Timely maintenance is conducive to “clearing out” hidden problems in the equipment and laying the foundation for efficient production.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.