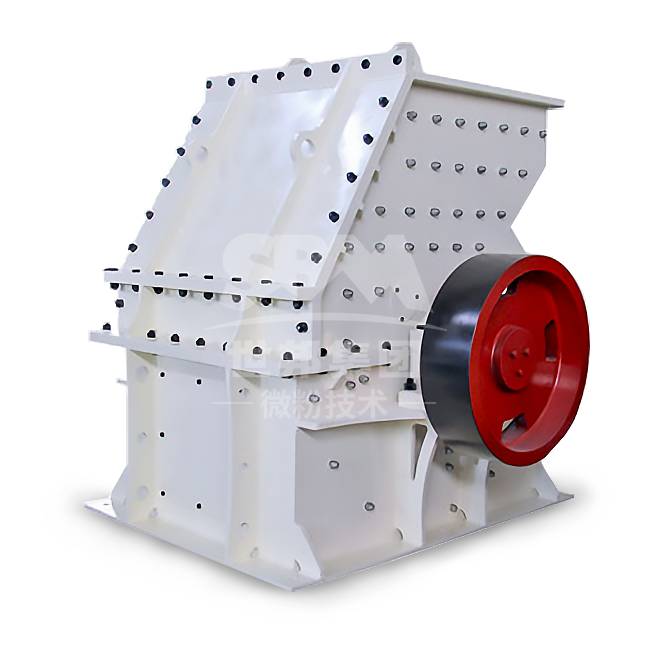

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

11/02/2022 admin

Stone crusher is the main crushing equipment in industrial crushing production. Because of its simple structure, convenient maintenance and repair, reliable operation and low production cost, it is widely used in medium-sized crushing of ore and bulk materials.

As a common crushing equipment, the crusher is used in a very harsh environment, and failure is an unavoidable and important problem of the crusher. However, if we can grasp the causes of common failures and how to solve them, we can better use the crusher for crushing operations.

Reason:

1. The bearing is damaged.

2. The discharge port is blocked, resulting in blockage of the complete cavity.

3. If the V-belt of the drive pulley rotates too loosely, it will cause the belt to slip.

4. The voltage at the work site is too low, and when the host encounters large materials, there is no way to complete the fracture.

5. The eccentric shaft fastening bushing is loose, there is no gap on both sides of the frame bearing seat, the eccentric shaft is stuck and cannot be rotated.

Solution:

Replace the bearing; remove the blockage at the discharge port to ensure that the material can be discharged smoothly; adjust or replace the V-belt, reinstall or replace the tightened casing, and adjust the voltage at the work site to match the working voltage.

Phenomenon: Locked rotor alarm

Solution: Check if there is any hard object jammed in the crusher when the power is cut off, whether the locked rotor switch is normal, and deal with it in time.

Phenomenon: The temperature of the main bearing exceeds the specified temperature

Solution: Check the amount of grease and pollution, check whether the bearing is damaged and deal with it in time.

Phenomenon: When the motor and reducer rotate, a small amount of coal overflows from the crusher

Solution: Check whether the fluid coupling is leaking or damaged, and deal with it.

When using the crusher, it is necessary not only to carry out regular maintenance, but also to carefully check whether there is any damage, timely repair, and replace parts to ensure the good operation of the equipment.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.