The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

18/02/2022 admin

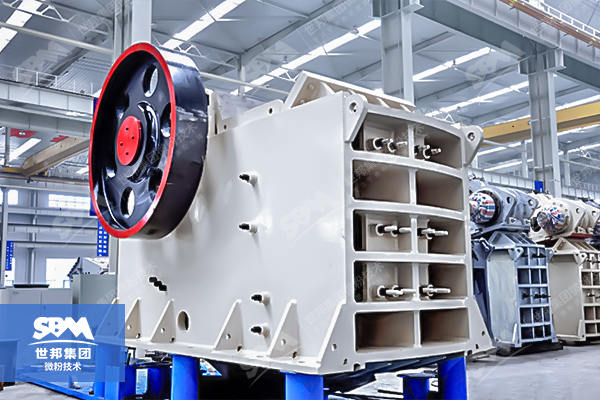

Jaw crusher and impact crusher are the main crushing equipment in ore crushing production line. The jaw crusher is used for coarse crushing of ore, and the impact crusher is used for medium and fine crushing of stone.

The jaw crusher handles high-hardness materials, and the impact crusher handles medium-hardness and brittle stones. So in addition, what are the differences between them?

Differences in use and production line location:

The jaw crusher is used for coarse crushing, and the impact crusher is used for medium and fine crushing. This is because:

a. The jaw crusher is the primary crushing equipment, which is the equipment for crushing the raw stone for the first time. The structure is simple and reasonable, and the hardness of the wear-resistant parts is high.

b. The impact crusher is a secondary feeding equipment, which is a device that crushes the discharged material after the jaw crusher is crushed again. It is not suitable for crushing high hardness stones such as granite and basalt, and has good crushing effect on brittle and soft stones.

Working principle difference:

a. During the operation of the jaw crusher, the motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft.

When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate, and at the same time, the material is crushed or chopped to achieve the purpose of crushing.

When the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the crushed materials are discharged from the lower opening of the crushing cavity.

b. When the impact crusher is working, the motor drives the rotor, and the material falls into the high-speed rotating turntable from the upper part of the machine.

Under the action of centrifugal force, the material will have a high-strength impact with another part of the material that is shunted around the turntable in an umbrella-shaped manner, and then broken.

After the two parts of the material are impacted and broken, a vortex movement will be formed between the turntable and the casing, resulting in multiple friction and crushing. After multiple cycles of crushing, it is finally discharged from the discharge port.

The difference between the fineness of the material and the particle shape:

The jaw crusher is coarse crushing, the discharge particle size is generally larger, and the finished product particle size is generally 10-350 mm. And due to the crushing principle of jaw crushing, the finished aggregate is more needle-shaped.

As a medium crushing and fine crushing equipment, the impact crusher has a finer discharge particle size. The impact crusher has both the function of shaping.

Performance advantage difference:

As a coarse crushing jaw crusher, the crushing cavity is deep and has no dead zone, so the crushing ratio is large, the production capacity is strong, the structure is simple and reasonable, the operation is reliable, the operating cost is low, the operation is environmentally friendly, and the adjustment range of the discharge port is large, which can meet the requirements of different customers.

The impact crusher has large feeding port, high crushing cavity, impact resistance and wear resistance. It is economical and reliable in operation, has strong crushing capacity, and has good comprehensive benefits. The finished aggregate has uniform particle size, beautiful grain shape and good selling price.

The crushing efficiency of the jaw crusher is not as high as that of the impact crusher. The main reason is that the jaw crusher does not perform work when discharging, and the rotor of the impact crusher keeps rotating. As long as the material enters the crushing cavity, it will be crushed.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.