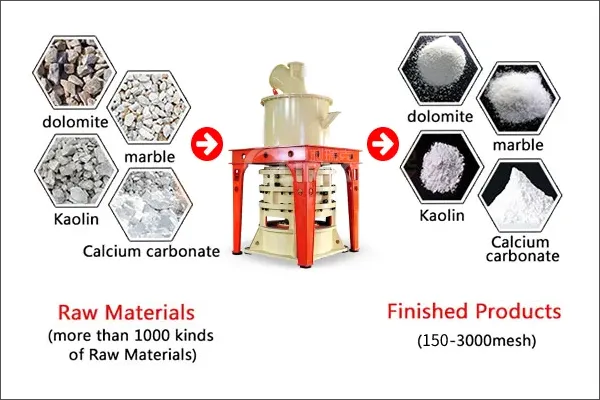

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

21/10/2022 admin

Ring roller mill and Raymond mill are two commonly used equipments for grinding stone powder in the mining industry, both of which belong to vertical mills. The difference between the ring roll mill and the Raymond mill is manifested in two aspects: the difference between the grinding system and the difference between the wind separation system.

Raymond mill

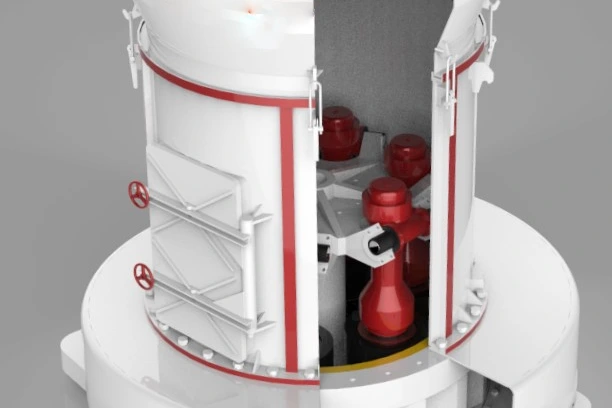

Ring roll mill

1. Difference of grinding system: Raymond mill adopts centrifugal pendulum suspension roller device for rolling, impact crushing. The number of rollers is generally 3-7, and the number of grinding rings is one. The contact surface between the grinding roller and the grinding ring is flat, and the interior is equipped with Blade feeder. The ring roller mill adopts a non-swing pin rolling structure for rolling and crushing. The number of rollers is 18-40, the number of grinding rings is 3-4, the contact surface between the grinding roller and the grinding ring is arc surface, and there is no blade feeding device inside.

2. Difference of air separation system: The powder separation system of Raymond mill is more diversified, most of them use circulating air separation system, and some ultra-fine Raymond mill series use full negative pressure powder separation system, with a wide range of fineness, such as coarse the coarsest powder Raymond mill can reach 40 mesh, the fine powder Raymond mill is 60-325 mesh, and the high-pressure Raymond mill is 60-800 mesh. The ring roller mill adopts a full negative pressure powder separation system, which is mainly suitable for processing ultra-fine powder, and the applicable fineness range is about 400-3500 mesh.

To sum up: Raymond mill has a simple structure and a wide range of applications. The ring roller mill has a complex structure and is mainly suitable for the ultrafine powder processing industry.

Structurally, the two types of equipment have the same composition, which is composed of a host, a powder separator, a powder collector, a motor, a fan, a pipeline, and an electronic control device.

In terms of use: these two types of equipment are used for grinding and processing materials, and are used in mining, building materials, metallurgy, chemical and other industries.

In terms of working principle: Ultrafine running-in Raymond mills use grinding rollers to squeeze and grind materials, and the specific grinding bodies are different.

The ultra-fine ring roll mill is more energy-saving. If the output and fineness are the same, compared with the Raymond mill, the system energy consumption of the ultra-fine ring roll mill is one third of that of the Raymond mill. Moreover, the grinding pressure of the ultrafine ring roll mill on the material is also 800-1200kg higher.

Compared with Raymond mill, ultra-fine powder mill has fewer production links, and the grinding device adopts overlapping multi-stage sealing, which has good sealing performance, and its dust removal effect can fully meet the national dust emission standard.

The ultra-fine ring roll mill has large output, high grinding efficiency, more energy saving, less dust, and meets environmental protection requirements. Compared with Raymond mill, the special technology of ultra-fine ring roll mill improves the fineness, precision and output of finished products.

Through the above comparison, we can see that although the appearance of the ring roller mill and the Raymond mill are not very different, their internal structures and material handling capabilities are quite different, so we should choose according to our own material conditions when choosing equipment. suitable equipment.

For example, the hardness of the grinding material is relatively large, and the ring roller mill should be selected if it exceeds the grade of 7.2. The fineness of the grinding material is relatively fine, and the ring roller mill should be selected for more than 600 meshes. The processing capacity is relatively large, and the ring roller mill should be selected.

If the material is more suitable and there is no special requirement for the fineness of production, then we need to compare the prices of the two and choose the one with higher cost performance.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.