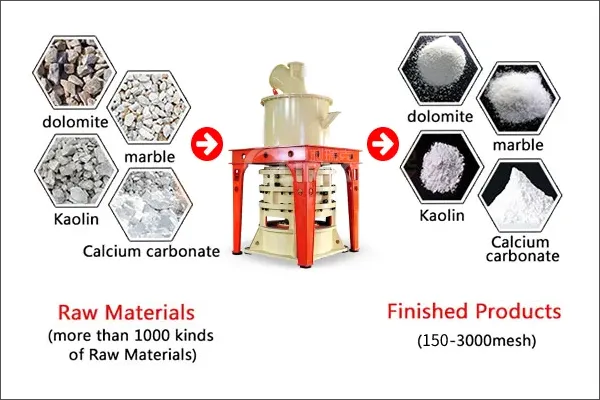

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

15/10/2022 admin

Sepiolite is a fibrous hydrous magnesium silicate, generally in the form of massive, earthy or fibrous aggregates. The color is usually white, light gray, light yellow, etc., opaque and not shiny. The unique structure of sepiolite determines that it has good adsorption properties, rheological properties and catalytic properties, and can be used in medicine, ceramics, casting, chemical industry, plastics, construction and other fields.

Sepiolite can be divided into two types: α-sepiolite and β-sepiolite: the former is produced in large bundles of fibrous crystals, which are usually called fibrous sepiolite; the latter is often produced in soil. It is composed of very thin and short fibers or fibrous aggregates, and is non-toxic, odorless, and non-radioactive.

The sepiolite powder, which has undergone a series of treatments such as purification, ultra-fine grinding and powder modification, can be used as adsorbents, purifiers, deodorants, reinforcing agents, suspending agents, thixotropic agents, fillers, etc. in water treatment, catalysis, rubber, paint, fertilizer, and other industries.

In addition, sepiolite’s good salt resistance and high temperature resistance make it used as a high-quality drilling mud raw material for oil drilling, geothermal drilling, etc.

The sepiolite grinding process is generally divided into two types: sepiolite fine powder processing (20 mesh-400 mesh) and ultra-fine powder deep processing of sepiolite (400 mesh-3250 mesh).

Stage 1: Broken

The large pieces of sepiolite are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

Stage 2: Grinding

The crushed sepiolite small pieces are sent to the silo by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the vibrating feeder for grinding.

80-600 mesh fine powder can be processed by YGM series high pressure suspension roller mill, and ultrafine powder larger than 600 mesh can be processed by HGM series ultra-fine powder mill or CLUM series vertical roller mill.

It can grind solid materials with Mohs hardness less than 9, and the fineness of finished products can be adjusted directly and freely between 80-600 mesh.

It can grind non-metallic ores with Mohs hardness less than 7, and the fineness of finished products can be freely adjusted between 150-2500 mesh. Small footprint, high efficiency and low consumption, environmental protection and no dust pollution…

It can grind non-metallic ores with Mohs hardness less than 7, and the fineness of finished products can be freely adjusted between 300-3000 mesh. Large output, high powder purity, energy saving and environmental protection…

Stage 3: Grading

The pulverized material is classified by the powder separator, and the unqualified powder is classified by the powder separator and then returned to the main engine for re-grinding.

Stage 4: Gathering Powder

The powder that meets the fineness enters the dust collector through the pipeline with the airflow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is uniformly packed by a powder tanker or an automatic baler.

The high-pressure suspension roller mill can be used to crush non-flammable and explosive materials such as barite, limestone, ceramics, slag, etc. with Mohs hardness not greater than 9.3 and humidity below 6%. It can process more than 280 kinds of materials, covering mining, metallurgy, chemical, building materials and other industries. The particle size of the high-pressure suspension mill can be freely adjusted in the range of 80-600 mesh.

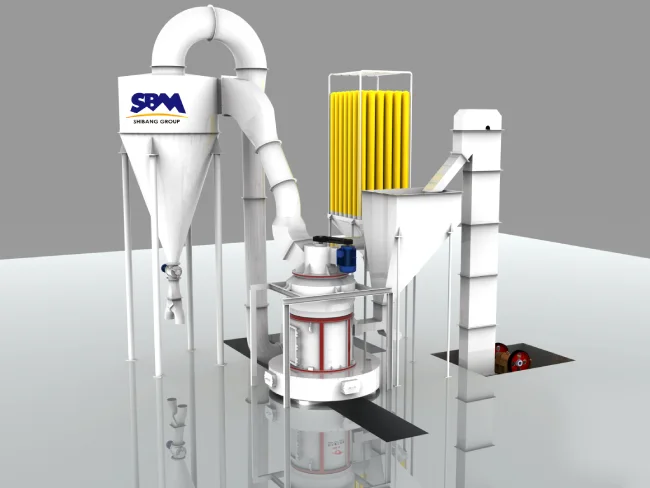

High pressure powder mill shows:

The complete production line of high-pressure suspension roller mill is composed of main engine, analyzer, piping device, blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control motor, etc. The main engine of the high-pressure mill is composed of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, a cover and a motor.

Working principle of high-pressure grinding mill:

The working principle of the high-pressure suspension roller mill is similar to that of the Raymond mill, but the grinding device is equipped with a high-pressure spring with a pressure of 1000-1500 kg. When the machine is working, under the action of high-pressure spring and centrifugal force, the grinding roller rolls close to the grinding ring, its rolling pressure is 1.2 times higher than that of the Raymond mill under the same conditions, and the output can be increased by 20%-30%.

When the material to be ground enters the grinding chamber, it is shoveled up by a shovel and sent to the grinding roller and the grinding ring for rolling.

After rolling, the powder is brought into the analyzer with the circulating air of the blower, and the qualified fine powder flows into the cyclone to collect the powder with the air. The device is the finished product, and the large particle material falls back for regrinding. The circulating air returns to the blower to repeat the above process, and the remaining air enters the bag filter for purification.

When the grinding roller and the grinding ring reach a certain level of wear, adjust the length of the high-pressure spring to maintain a constant grinding pressure between the grinding roller and the grinding ring, so as to ensure stable output and fineness.

| Model | Roller | Ring | Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

High pressure powder mill is a derivative of Raymond mill (Raymond mill can crush limestone, gypsum and other rocks very well). There is no obvious difference in appearance between high pressure suspension roller mill and Raymond mill, and the main difference is reflected in the feed particle size, discharge particle size, finished product output and so on.

In terms of feed particle size: the smaller the original Raymond mill feed, the more stable the output and the higher the processing efficiency, while the feed particle size of the high-pressure suspended roller mill is larger than that of the Raymond mill.

In terms of discharge particle size: the processing discharge particle size of Raymond mill is in the range of 30 mesh to 325 mesh, and the discharge particle size of high-pressure mill is in the range of 80 mesh to 600 mesh. The finished product is finer, and the sieving rate is higher.

In terms of finished product output: the high-pressure mill has a higher output than the Raymond mill due to the strong pressure of the high-pressure spring.

The high-pressure grinding mill adopts a mature high-pressure device, which can not only prolong the service life of the equipment, but also increase the grinding output of the equipment to the same extent. Ordinary Raymond mills do not have this advantage. During long-term use, when the wear of the grinding rollers and grinding rings is large, even if the bolts and other parts are adjusted, they cannot be ground tightly, and the finished powder will not meet the requirements. Fineness, at this time, only wearing parts can be replaced.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.