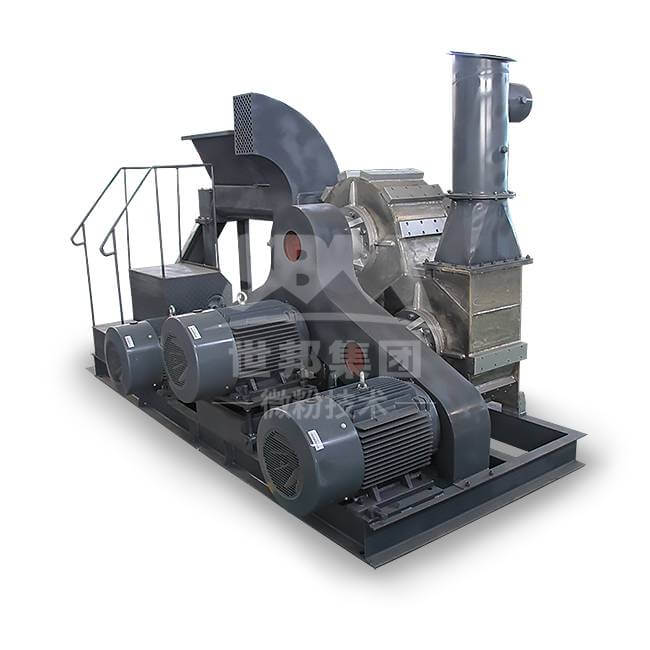

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

01/04/2022 admin

In the naked eye identification, the appearance properties of high-quality bentonite are mostly pure white, generally gray or yellow-white, often light green, light blue, rose red and other colors due to water absorption or impurities. It remains pure white, gray or light yellow-white after air-drying.

The broken section of bentonite is not smooth, and it is jelly-like. The surface of bentonite ore has an oily luster and feels slippery to the touch. It can absorb water and swell, and can become colloid in good quality. If it is air-dried for a long time and the water is lost, it can become loose again.

Bentonite can absorb or absorb various colors because of its strong ion exchange force. Mix it with grease to make the grease more slippery. Its fine powder is a suspension of water, and the dispersion is very good, and it is not easy to precipitate.

The types of natural bentonite are mainly divided into calcium, sodium, hydrogen, hectorite, etc. according to the relative content of the cations of montmorillonite, among which the clay mainly composed of calcium montmorillonite is called calcium-based bentonite.

Bentonite is often divided into two categories: calcium-based bentonite and sodium-based bentonite. Among them, calcium-based bentonite refers to untreated bentonite powder, while sodium-based bentonite is a product obtained by replacing cationic soda ash with sodium ions.

The identification method of bentonite is similar to the identification of general ore materials, and it depends on its color first. The color is dull, and those that do not swell with water are generally not good products. Appearance color is an indicator of the identification method, and sometimes it cannot be generalized, and accurate conclusions can only be drawn by relying on tests and tests

High-quality bentonite is generally called pure white, and the higher the whiteness, the higher the product quality. But some are gray or yellow, often due to water or impurities in the water, turning into light green, light blue or iron red and other colors. Good bentonite ore body with greasy luster and smooth hand. These are the outward manifestations of high-quality bentonite products. The surface of compacted and hardened bentonite is not smooth after crushing, and some water can become jelly-like, and no water can become a dense hard mass.

Bentonite clay is available in the following three colors, each with different uses:

Red bentonite: used in veterinary drugs, pesticides, coatings and other industries.

Yellow bentonite: used in drilling mud, engineering piling, directional crossing, geological exploration, pipe jacking construction and other industries.

White bentonite: used in chemical coatings, compound fertilizer, mortar, mortar, rubber, desiccant, stabilizer and other industries.

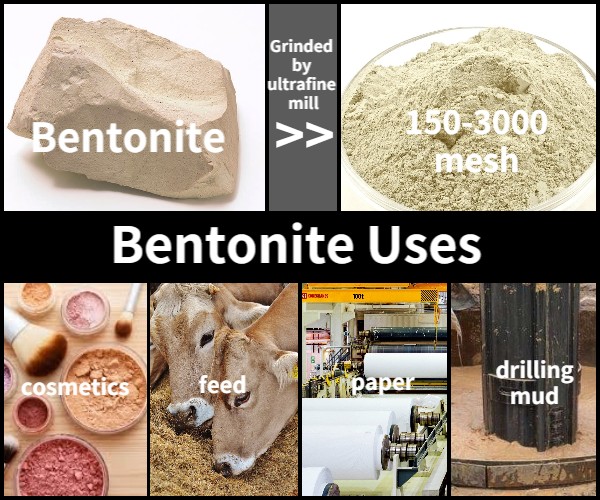

The key production equipment used in the bentonite grinding production line are jaw crusher, impact crusher, Raymond mill, ultrafine mill, etc. In addition, some auxiliary machinery and equipment, such as bucket elevators, vibrating feeders, powder separators, belt conveyors, dust collectors, fans, etc. Together, it constitutes a detailed bentonite production and processing production line.

In order to improve the practical value of bentonite and expand the scope of application of natural bentonite, it is necessary to modify the natural inorganic bentonite into organic bentonite. In the modification process of bentonite, it is necessary to add modifier to make bentonite have the ability to adsorb organic compounds, so as to reach the standard of organic bentonite. Commonly used modifiers include inorganic modifiers, organic modifiers, and inorganic-organic composite modifiers.

Powder Surface Coating Machine

Capacity: 40-7000 kg/h

Max feeding size: Optional

Processing ability: 40-7000 kg/h

Range of application: Heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesium-hydroxide bariumcarb, illite claystone and pyrophyllite, hexagonite, etc.

In the modification process, there are two methods: chemical modification and physical adsorption modification. Physical adsorption modification is based on the ability of organic polar compounds to replace the adsorbed water between montmorillonite layers and cause non-ionic reactions to make organic polar compounds. It is adsorbed on the bottom surface of the unit crystal layer by van der Waals force. The organic bentonite produced by this method is relatively stable and is currently used in a wide range. Chemical modification is to achieve chemical modification by ion exchange between surfactants and exchangeable cations in montmorillonite, and the commonly used active agent is “organic ammonium salt”.

In the actual modification process, chemical modification and physical modification coexist, and they work together. In the process of chemical modification, when organic ions interact with montmorillonite, there are both ionic bonds, covalent bonds and van der Waals forces. In general, when organic cationic quaternary ammonium salts are used as organic modifiers, the modification is mainly chemical modification; if organic amines are used as organic modifiers, it is mainly physical modification.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.