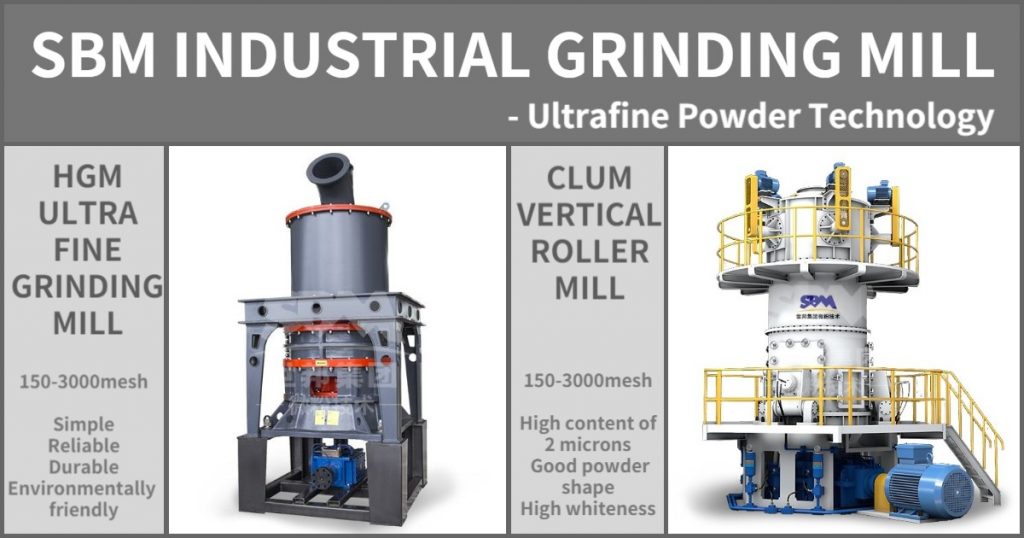

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

03/01/2023 admin

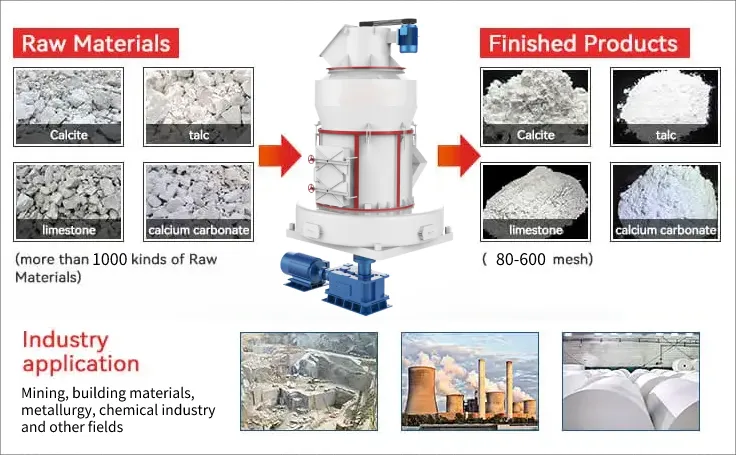

Zircon sand is a mineral whose main component is zirconium silicate. Pure zircon sand presents a colorless transparent crystal. Due to different impurities, zircon sand will appear yellow, orange, red, brown, etc. color. Zircon sand is widely used in construction, ceramics, glass, medicine, abrasives, chemical industry, metallurgy and other fields.

The zircon sand Raymond mill is mainly used for the grinding operation of zircon sand materials. This equipment is a relatively advanced grinding equipment in the field of grinding at present. It has the advantages of advanced structure, stable performance, and less maintenance.

The technological process of zircon sand powder is generally divided into two types: zircon sand fine powder processing (200 mesh-400 mesh), and zircon sand ultrafine powder deep processing (600 mesh-2500 mesh). The processing process is generally as follows:

Mining and dressing of zircon sand raw ore → Crushing of zircon sand raw ore: Generally, jaw crusher is used to crush the raw material to the fineness that can enter the mill (15mm-50mm)

→Zircon sand milling: fine powder processing generally adopts CLRM series Raymond mill (zircon sand Raymond mill), YGM high pressure mill and other milling equipment for processing; ultrafine powder processing generally adopts HGM ultrafine ring Roll mill (zircon sand ultrafine powder mill) or CLUM ultrafine vertical mill (zircon sand vertical mill) for processing

→Storage and packaging of zircon sand powder: After the finished powder is collected by the powder collection system supporting the mill (ultra-fine vertical mill is equipped with a multi-head classifier for ultra-fine powder), it is transported to the finished product is stored in the powder tank, and then uniformly loaded into the powder tank truck or bagged and packaged.

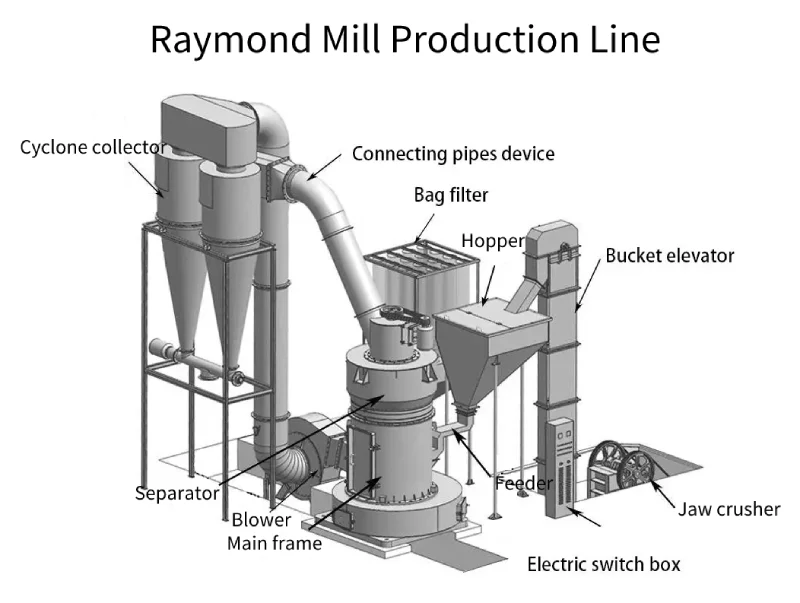

According to the entire production process of zircon sand powder, the whole set of zircon sand powder grinding production line equipment has the following mechanical configuration:

(1) Jaw crusher (2) Vertical mill (Raymond mill, zircon sand superfine powder mill) (3) Storage tank (4) Elevator (5) Feeder (6) reducer (7) powder analysis machine (8) fan (9) pulse dust collector (10) powder collector (11) powder packaging machine.

When the zircon sand mill is working, firstly, the materials that meet the feeding requirements of the mill are sent into the main mill chamber of the zircon sand mill through the fan, and the materials are rolled and pressed between the grinding roller and the grinding ring to reach the of crushing.

After the material enters the main casing, the blown powder will enter the analyzer for sorting, and the powder that does not meet the particle size requirements will be re-ground until it is qualified, and the zircon sand materials that meet the particle size requirements will enter the finished product cyclone collector, and then pass through the powder tube. Discharge is the finished product.

● High quality finished product

The sieving rate of the finished product of the equipment can reach 99%, the fineness of the finished product is small, and the particle size is uniform. Compared with the general equipment, it can produce high-quality finished products.

● Simple process

The zircon sand mill adopts a three-dimensional structure, which occupies a small area and is highly complete. It forms an independent production system from block material to finished powder.

● Easy to maintain

The zircon sand mill adopts a centralized control electrical system, which can realize unmanned operation, which makes the maintenance of the equipment less and the maintenance work is easier.

● High wear resistance and long service life

The important parts of the equipment are made of high-quality wear-resistant materials, and the whole machine has high wear resistance. The transmission device adopts a closed gear box and a pulley, which is reliable in operation and greatly improves the overall service life of the equipment.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.