The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

13/09/2022 admin

Coal gangue is a mixed rock mass discharged during the construction and production of coal mines.

Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill. Coal gangue powder is widely used in the construction field.

1. Brick making with coal gangue powder

Coal gangue powder is the raw material for making solid gangue bricks, porous load-bearing gangue bricks, hollow gangue bricks and other brick-laying materials.

2. Coal gangue powder replaces clay to produce cement

The price of cement has skyrocketed. Coal gangue powder replaces clay to produce cement for the construction of high-rise buildings. The weight of the building is reduced by 20%, which not only saves construction costs but also increases the safety of the building.

3. Coal gangue powder as cement mixture

Coal gangue powder is mixed into cement to make active mixed material, which is matched with clinker and gypsum in proportion. It is a good aggregate in construction production.

The production process of coal gangue pulverizing is mainly composed of feeding, coarse crushing, medium and fine crushing, grinding, screening, transportation and other links. Commonly used equipment includes vibrating feeder, vibrating screen, belt conveyor, jaw crusher, impact crusher, ultrafine powder mill and other equipment.

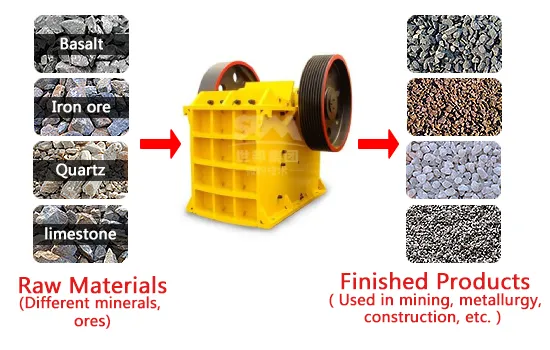

① Initial crushing stage: the main processing equipment is jaw crusher; auxiliary equipment is vibrating feeder.

The initial crushing process is as follows: the vibrating feeder feeds the large coal gangue directly and evenly and quantitatively to the jaw crusher. After being crushed by the jaw crusher, it is discharged out of the machine through the discharge port and is transported to the medium and fine crushing processing section by the belt conveyor.

② Medium and fine crushing stage: the main processing equipment is the impact crusher, and the auxiliary equipment is the vibrating screen.

The medium and fine crushing process is as follows: the coarsely crushed gangue material is directly fed to the impact crusher by the belt conveyor. After the material is crushed again by the impact crusher, it is discharged through the discharge port, and then brought to the vibrating screen by the belt conveyor for screening. The sifted coal gangue is divided into two directions, the larger particle size is returned to the impact crusher to be broken again, and the smaller particle size is directly transported to the grinding section.

③ Grinding stage: the main processing equipment is HGM ultrafine powder mill, auxiliary equipment powder separator, powder collector, etc.

The grinding process of ultrafine powder mill is as follows: the vibrating feeder evenly sends small pieces of coal gangue into the ultra-fine grinding mill. When the mill is working, the main motor drives the main shaft and each layer of turntables to rotate through the reducer, and the turntable drives dozens of ring rollers to roll and rotate in the grinding ring raceway through the pins. After being crushed by the first layer, the coal gangue falls into the second layer and the third layer and is repeatedly and fully ground.

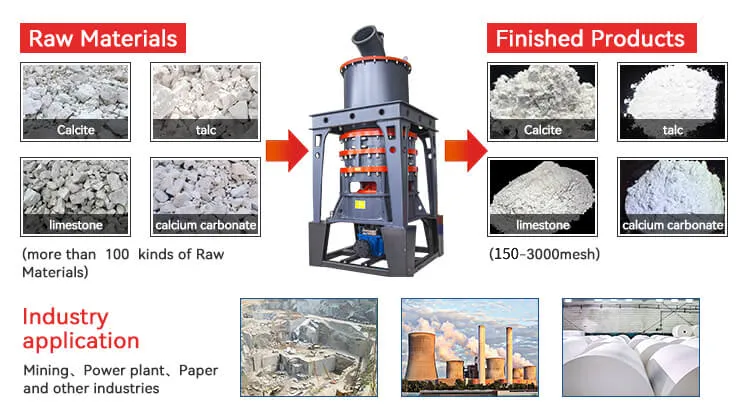

HGM series ultrafine powder mill is mainly suitable for superfine powder processing of non-flammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6.

There are more than 100 kinds of processable materials, the common ones are calcite, chalk, limestone, dolomite, carbon black, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate rock, potassium ore, pumice, etc.

The particle size of the finished fine powder can be adjusted arbitrarily between 150-3000 mesh, and the output can reach 0.2-45 tons per hour.

CONTACT US NOW!!! WhatsApp: +86 18917951321

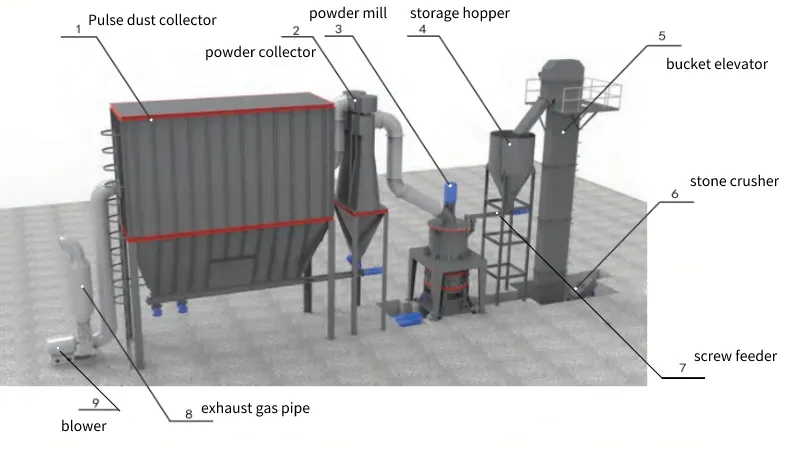

When working, the main motor drives the main shaft and the turntable to rotate through the reducer, and the roller pins on the edge of the turntable drive dozens of grinding rollers to roll in the grinding ring raceway.

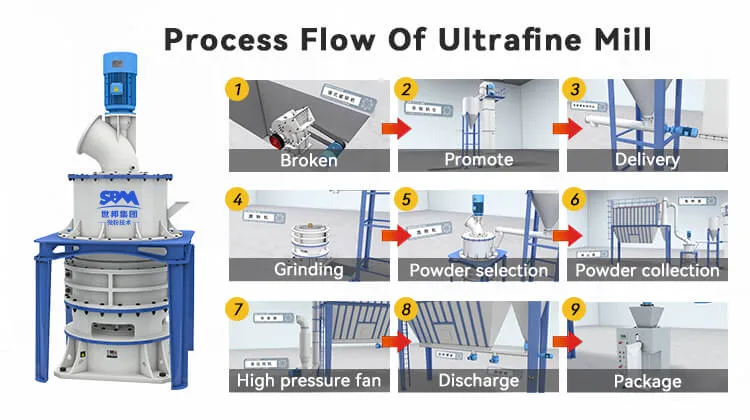

The bulk materials are crushed into small particles by the hammer crusher, and then sent to the storage bin by the elevator, and then sent to the bulk tray on the upper part of the turntable evenly through the vibrating feeder and the inclined feeding pipe.

The material is scattered to the periphery of the circle under the action of centrifugal force, and falls into the raceway of the grinding ring, which is impacted, rolled and ground by the ring roller, and becomes powder after the processing of the three-layer ring.

The high-pressure fan sucks the external air into the machine through suction and brings the pulverized material into the classifier. The rotating impeller in the powder separator makes the coarse material fall back for regrinding, and the fine powder that meets the requirements enters the cyclone powder collector with the airflow and is discharged from the discharge valve at the lower part of the powder, which is the finished product.

The airflow with a small amount of fine dust is purified by the pulse dust collector and discharged through the fan and muffler.

● High efficiency and high output

In the case of the same fineness of finished products and the same motor power, the output is more than 1 times higher than that of jet mill, stirring mill and ball mill.

● The wearing parts have a long service life

Grinding rollers and grinding rings are forged with special materials, which greatly improves the utilization. Under the condition of the same fineness of materials and finished products, the service life is 2-5 times longer than the wear parts of impact crusher and turbo crusher, generally more than 2 years. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

● High safety and reliability

Because there is no rolling bearing and no screw in the grinding chamber, there is no problem that the bearing and its seals are easily damaged, and there is no problem that the screw is easy to loosen and damage the machine.

● High product fineness

The fineness of HGM series ultra-fine grinding products can reach D97≤5μm at one time.

● Environmentally friendly and clean

The pulse dust collector is used to capture dust, and the muffler is used to reduce noise, which is environmentally friendly and clean.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.