The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

Material: Gypsum

Fineness: 1600mesh

Capacity: 12 t/h

Purpose: Widely used in building materials, chemicals, molds, food industry and foundry industry, etc.

This customer needs an industrial grinding mill for grinding his material – Gypsum.

And the customer requires the finished product to have a particle size of 1600 meshes.

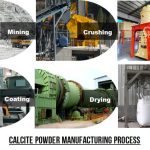

According to the customer’s production needs, our technicians design the production line for the customer for free.

And recommend the customer to use the HGM ultrafine grinding mill with high-cost performance.

The right pic is of his factory site.

Gypsum powder is one of the five major gel materials. It is widely used in many application fields.

Such as construction, building materials, industrial molds, and art models, chemical industry and agriculture, food processing, and medical beauty.

It is an important industrial raw material, usually white, colorless. Sometimes due to impurities in gray, light yellow, light brown, and other colors.

HGM Ultrafine Grinding Mill – used in this customer case

HGM ultrafine grinding mill is a high-efficiency and energy-saving industrial grinding mill. You can use it to grind hard stones into fine powder.

This fine powder mill is suitable for the superfine grinding of all kinds of crisp materials whose Moh’s hardness is below 7.

Such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory material, glass, total about 1000 kinds of materials (with finished product size 325-3000 mesh).

Benefits of HGM ultrafine grinding mill:

1. Compact structure

2. Adjustable product fineness

3. Low energy consumption of the unit product

4. Convenient maintenance and low investment

5. The crushing, grinding and classification of the material are completed in a closed system. The dusty gas is processed by the dust collector, so it is the green and ideal equipment for environmental protection.

Uzbekistan

Uzbekistan

Material: Talc

Fineness: 400mesh

Capacity: 20ton per hour

Bangladesh

Bangladesh

Material: Gypsum

Fineness: 1250mesh

Capacity: 14 t/h

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.