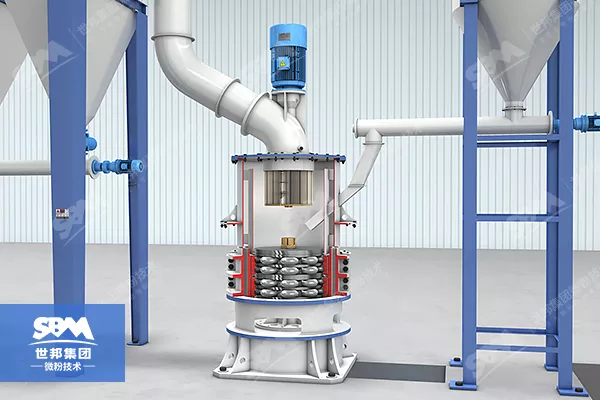

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

09/09/2021 admin

Diatomaceous earth is a siliceous mineral. The main chemical composition is amorphous SiO2, and the content of SiO2 is generally above 80%. Contains a small number of impurities, mainly including Al2O3, Fe2O3, CaO, MgO, K2O, Na2O, P2O5, and organic matter. The appearance of diatomaceous earth is white, off-white, light gray, light yellow, and dark gray.

Diatomaceous earth is formed by the deposition of the remains of single-celled aquatic plant diatoms. The unique property of diatoms is that they can absorb free silicon in water to form bones. After the death of diatoms, they deposit and form diatomaceous earth deposits under certain geological conditions. Diatomite has some unique properties, such as porosity, lower density, larger specific surface area, relative incompressibility, and chemical stability.

Neutral pH value, non-toxic, good suspension performance, strong adsorption performance, excellent extensibility, high impact strength, tensile strength, tear strength, lightweight, good internal abrasion, good compressive strength, sun protection Strong, strong lubrication performance.

The main uses of diatomite are fillers, filter aids, catalytic carriers, adsorbents, environmentally friendly building materials, and so on.

Packing

Mainly used in coatings, plastics, rubber, medicine, papermaking, abrasives, precision castings, and microporous ceramics.

Diatomite used as a filler in paint coatings can improve the stability, elasticity, and dispersion of the product, and improve the strength, wear-resistance, and acid resistance of the product.

As a functional filler, diatomaceous earth can also play a role in matting. For example, adding diatomaceous earth to the silicone rubber can enhance the oil resistance and heat resistance of the rubber, and improve the processing performance.

Using diatomaceous earth as a filler to produce cardboard, save paper pulp, not only reduces production costs but also improves the cleanliness and strength of the cardboard.

High-quality diatomaceous earth is added to automobile brake linings and asbestos friction plates for the machinery industry. It is very easy to combine with resin and other materials. It has a special combination with rubber oil. It has both filling and reinforcing effects. And it can overcome the thermal decay performance of the product and enhance its adaptability of the product.

Diatomite itself has a large number of micropores, so it is a good filler for preparing microporous ceramic membrane tubes. Using high-quality selected diatomaceous earth as a filler, a diatomaceous earth microporous ceramic membrane tube can be developed.

Filter aid

The main application areas are the beer industry, pharmaceutical industry, water purification filtration, oil industry, mailing solutions, coatings and dyes, fertilizers, acids, alkalis, seasonings, sugars, alcohol, and other filtration.

Catalytic carrier

Diatomaceous earth has a suitable specific surface area, high porosity, abrasion resistance, acid resistance, heat resistance, and other characteristics, and becomes an ideal carrier for catalysts for hydrogenation, oxidation, hydration, dehydrogenation, reduction, and other reactions.

The antibacterial agent using diatomaceous earth as the carrier of the antibacterial agent, due to the strong adsorption capacity of diatomaceous earth, the antibacterial liquid is absorbed into the micropores of the diatomaceous earth and released slowly, so it becomes a long-acting antibacterial agent.

For the antibacterial agent using diatomaceous earth as the carrier, the antibacterial ring is basically the same for 40d and 2d, while the antibacterial ring is significantly smaller for the antibacterial agent without using diatomaceous earth as the carrier.

Sorbent

The adsorption of diatomite is mainly physical adsorption, which has a fast adsorption rate and strong adsorption capacity. It is mainly used for urban sewage, papermaking wastewater, printing and dyeing wastewater, slaughter wastewater, oily wastewater, and heavy metal wastewater.

The application of diatomaceous earth as an adsorbent is similar to that of filter aids. When used in the adsorption and refining of food, it is required to meet hygienic standards.

Environmentally friendly building materials

Due to its special structure, diatomite is an excellent choice for diatom mud ecological wall materials.

The wall material produced with diatomaceous earth has the characteristics of ultra-fiber, porous and other characteristics, and its ultra-fine pores are 5000 to 6000 times more than that of activated carbon.

When the indoor humidity rises, the ultra-fine holes on the diatomaceous earth wall material can automatically absorb the moisture in the air and store it.

If the moisture in the indoor air decreases and the humidity decreases, the diatomaceous earth wall material can release the moisture stored in the ultra-fine pores.

Secondly, the diatom mud ecological wall material also has the function of eliminating the peculiar smells and keeping the room clean.

Used in the bathroom of homes and hotels, it can remove odorous gases such as hydrogen sulfide and ammonia, kill harmful bacteria, and prevent the spread of diseases.

Used in the car interior, it can remove the harmful gas emitted by the interior decoration products of the car, and at the same time remove the smell of body odor, oil, smoke, or vomiting due to motion sickness.

1. Surface groups and adsorption properties of diatomite

The surface of diatomaceous earth contains a large number of different kinds of hydroxyl groups. The more hydroxyl groups, the better the adsorption performance of the diatomaceous earth. After some treatments, the hydroxyl groups of diatomaceous earth will be transformed, thereby changing the adsorption performance of diatomaceous earth. These hydroxyl groups have certain activities, so they can also change the adsorption properties of diatomite by reacting with other substances or forming bonds.

2. Surface charge of diatomaceous earth

Diatomite particles exhibit a certain degree of negative charge. The surface of diatomite is negatively charged in most pH ranges, but under acidic conditions, the hydroxyl groups on the surface of diatomite are protonated, so they are positively charged. Grafting functional groups on the surface of diatomite can move the isoelectric point of diatomite.

3. Surface structure and adsorption characteristics of diatomite

The specific surface area of domestic diatomaceous earth is 19~65m3/g, the pore radius is 50nm~800nm, and the pore volume is 0.45~0.98cm3/g. Pretreatment such as pickling or roasting can increase its specific surface area and increase pore volume. The adsorption characteristics of diatomite are closely related to its physical and chemical structure. Generally, the larger the specific surface area, the greater the adsorption capacity; the larger the pore size, the greater the diffusion rate of the adsorbate in the pore size, which is more conducive to achieving adsorption equilibrium. But under a certain pore volume, when the pore size is fixed, the larger the pore volume, the larger the adsorption capacity.

Diatomite ore generally contains more impurities, and there are more obvious physical and chemical structural defects, which greatly limit the adsorption capacity of diatomite. Therefore, it is necessary to modify diatomaceous earth to improve its adsorption capacity. The following introduces some modification methods commonly used by researchers at home and abroad.

1. Conventional modification

(1) Scrub method

The scrubbing method is to grind the diatomaceous earth without damaging the diatom frustules, and the raw material particles are fined, so as to peel off the clay and other minerals on the diatom frustules, increase the content of SiO2, and improve the surface properties of the diatomaceous earth particles. And then improve its adsorption capacity.

(2) Roasting method

High-temperature calcination can effectively increase the content of SiO2 in diatomaceous earth, increase the pore size, and increase the surface acid strength. Studies have shown that when the calcination temperature is lower than 450℃, increasing the calcination temperature will help increase the specific surface area of diatomaceous earth. The specific surface area reaches the maximum at 450℃, and then increases the calcination temperature, the specific surface area begins to decrease. When the temperature exceeds 900°C, roasting will destroy the framework of the diatom.

(3) Microwave method

Proper microwave treatment of diatomaceous earth can effectively remove part of the impurities and moisture in the diatomaceous earth, increase the pores of the diatomaceous earth, thereby increasing its surface area and improving the adsorption effect. Studies have shown that with the extension of microwave irradiation time, the adsorption capacity of diatomaceous earth increases, but after the irradiation time reaches 15min, the adsorption capacity continues to decrease with the extension of time.

(4) Acid modification

Acid modification is mainly to remove impurities on the surface of diatomaceous earth particles through the etching action of strong acid, improve their purity, increase their pore volume and specific surface area, significantly improve the pore structure of diatomaceous earth, and improve its surface adsorption performance.

2. Inorganic modification

Inorganic modification of diatomite is mainly by adding inorganic macromolecular modifiers to make it uniformly dispersed in the diatomite pores to form a columnar layered association structure, dredge or expand the diatomite pores, and associate particles A larger space is formed between them to accommodate more adsorbates, and ultimately achieve the purpose of improving the adsorption capacity of diatomite.

3. Organic modification

The organic modification of diatomite mainly refers to grafting organic functional macromolecules on the surface of diatomite and modifying the surface to achieve the purpose of improving the adsorption capacity of diatomite. Commonly used modifiers include cetyltrimethylammonium bromide and polyethyleneimine.

In practical applications, in order to achieve the best use of diatomite, more than one modification method is often used, and various modification methods should be organically combined to form a modification process that can more effectively improve some of the diatomite performance, make full use of diatomite resources.

Click here to learn more about diatomaceous earth mills through this article.

In the realm of industrial mineral processing, the demand for robust, high-output rock pulverizer machines has never been greater. Among the most advanced solutions in this field is the HGM series of ultrafine grinding mills, engineered to deliver precision, durability, and scalability for large-scale operations. This article delves into the flagship HGM125 model and its…

A ring mill, also known as a ring roller mill, micro powder grinding mill, or ultrafine grinding mill, is a type of grinding equipment commonly used in the industrial production of ultrafine calcium carbonate.

The CLQM series Airflow Vortex Mill Powder Micronizer is designed for processing a wide range of materials, offering uniform particle sizes that can be adjusted according to specific requirements. The CLQM airflow vortex mill powder micronizer is capable of grinding materials to micron and sub-micron levels, making it highly versatile and suitable for processing difficult-to-handle…

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultra-fine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying.

Ultrafine vertical mill is a high-efficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc

Carbon black is a light, loose and fine black powder that contains carbon substances. It can be used as a black dye to make ink, paint, rubber material, etc. Carbon black ultrafine mill is also called (three-ring four-ring) medium-speed ring roller micro-grinding machine. It adopts a graded continuous grinding method to grind the material multiple…

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.