The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

30/09/2025 admin

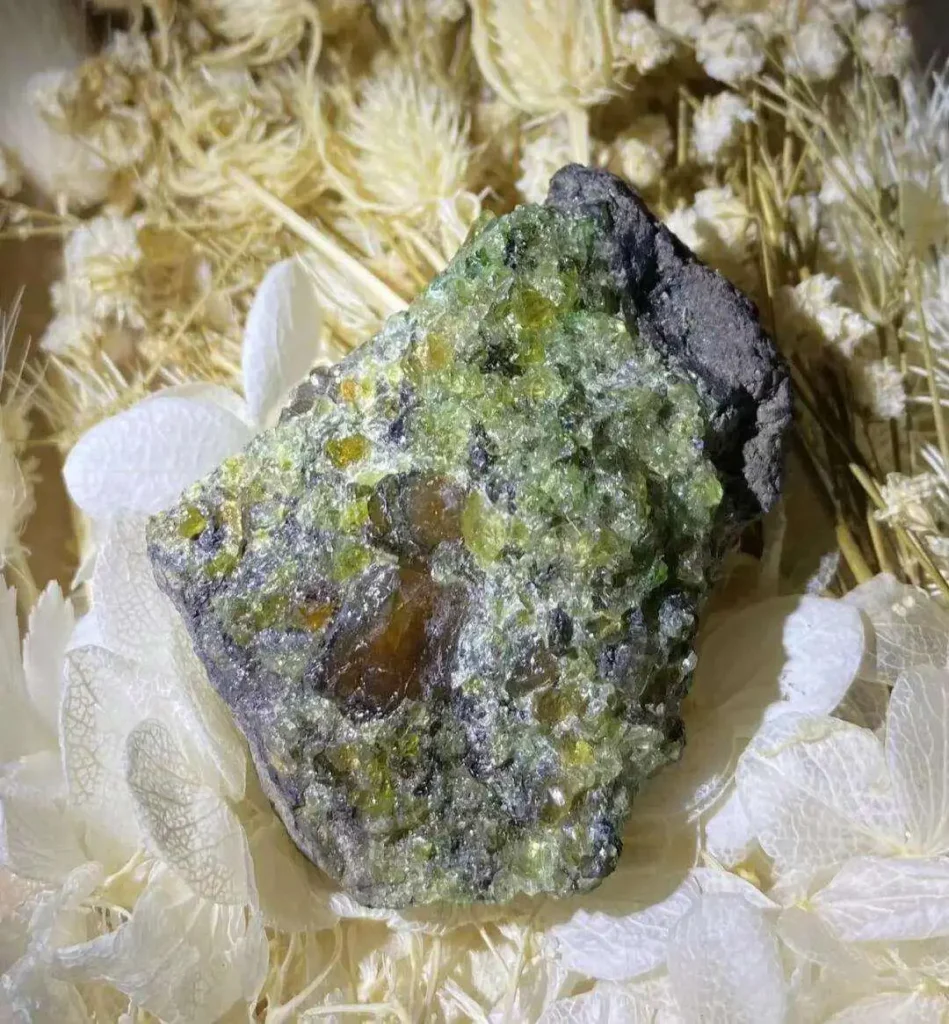

Mineral Mill for Raw Olivine Sand: We offer advanced grinding solutions with HGM Ultrafine Mill and CLRM Raymond Mill for efficient olivine powder processing.

To transform raw olivine sand into industrial-grade fine powders, advanced mineral mill solutions are essential. As a leading Chinese manufacturer of grinding mills, we offer cutting-edge technologies to meet this demand. Our flagship equipment, the HGM ultrafine mill and the CLRM Raymond mill, provide efficient, precise, and environmentally friendly grinding solutions tailored to non-metallic minerals such as olivine.

Olivine is a magnesium iron silicate mineral with the general formula (Mg,Fe)₂SiO₄. It is one of the most abundant minerals in Earth’s upper mantle and occurs in igneous rocks such as basalt, gabbro, and peridotite. When weathered and crushed, it becomes raw olivine sand, which is widely available and cost-effective.

To fully exploit these applications, olivine must be ground into powders of specific particle sizes. This is where our mineral mill solutions come into play.

Processing raw olivine sand into industrial-grade powders requires controlled grinding. A mineral mill is designed to reduce particle size, enhance purity, and achieve consistent fineness. The importance of grinding equipment can be summarized as follows:

We provide comprehensive grinding solutions for olivine, with two primary models:

Both mills are proven choices for processing raw olivine sand into industrial-grade powders

The HGM series ultrafine mill is our flagship solution for processing non-metallic minerals. For raw olivine sand, it delivers ultra-fine powders suitable for high-end applications.

The CLRM Raymond mill is a reliable and cost-effective solution for processing medium to fine powders. It is widely used for grinding raw olivine sand into powders suitable for refractory and metallurgical applications.

| Feature | HGM Ultrafine Mill | CLRM Raymond Mill |

|---|---|---|

| Fineness Range | 325–3000 mesh | 80–600 mesh |

| Output Capacity | 0.5–45 t/h | 1–25 t/h |

| Applications | High-end industries, CCS, paints | Refractory, metallurgy, abrasives |

| Energy Efficiency | Very high | Moderate |

| Price Range | Higher (premium technology) | Lower (cost-effective) |

| Best Use for Olivine | Carbon capture, coatings, fillers | Refractory, sandblasting, steelmaking |

By combining both mills, customers can create a comprehensive olivine powder production line that covers a wide spectrum of particle size requirements.

Processing raw olivine sand into high-value powders requires advanced, efficient, and reliable mineral mill solutions. HGM ultrafine mill and CLRM Raymond mill offer the ideal combination of precision, efficiency, and cost-effectiveness to meet these needs.

Whether producing ultrafine olivine powders for carbon capture technologies or medium-fineness powders for refractory and metallurgical applications, our mineral mills ensure stable production, low energy consumption, and high economic returns.

Jaw Crusher

Feed particle size: 0-1020mm

Production capacity: 45-800 tons/hour

Applicable materials: granite, marble, basalt, limestone, quartz stone, river pebbles, iron ore, copper ore, etc.

Features: Simple structure, reliable performance, welded frame, mechanical adjustment, longer service life

Hammer Crusher

Feed particle size: <350 mm

Finished product fineness: 5-20 mm

Production capacity: 5-30 t/h

Product features: compact structure, few wearing parts, easy maintenance, sealed body structure

Cone Crusher

Production capacity: 27-1400t/h

Feed particle size: 369mm

Finished product fineness: 3-100mm

Product features: traditional structure, reliable function, hydraulic jacking, overload protection system, independent lubrication system, easy maintenance

Impact Crusher

Feed particle size: 0-350mm

Production capacity: 50-260 tons/hour

Applicable materials: limestone, feldspar, calcite, talc, barite, dolomite, kaolin, gypsum, graphite, etc.

Product features: simple and reliable structure, fully mechanical adjustment, high production efficiency and long service life

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.