The products of Shibang Industry & Technology Group, Shanghai Ultrafine Powder Tech. Co., Ltd. are widely used in various industries of modern industry, such as metallurgy, building materials, chemical industry, mining, papermaking, ceramics, plastics, composite materials, rubber and coatings.

Regularly report real-time dynamic information of domestic and foreign mining and mineral powder industry.

Rhyolite is a silica-rich volcanic rock widely used in construction materials and ceramics.Processing involves crushing → grinding → classification to achieve different applications. Rhyolite is a type of volcanic igneous rock that forms from high-silica (acidic) lava. It is chemically similar to granite, but because it cools quickly on or near the Earth’s surface, its […]

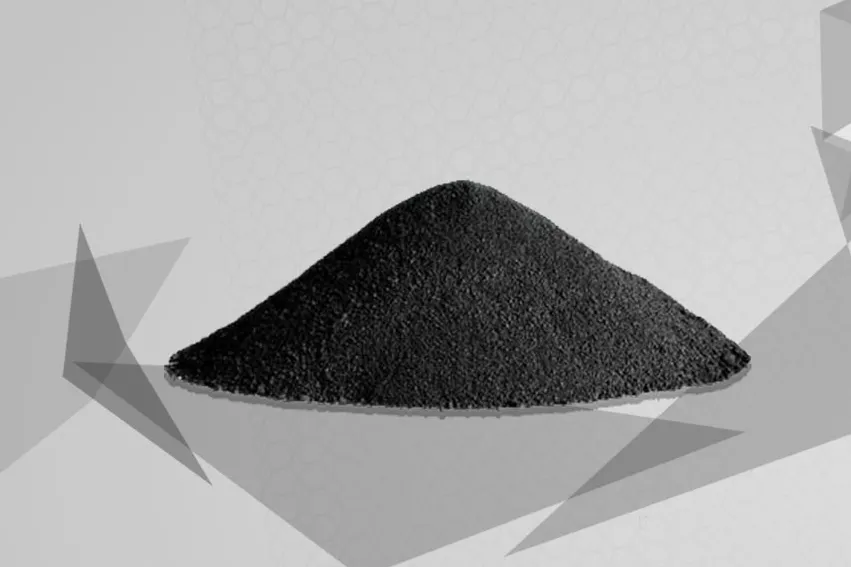

The industrial pursuit of high-performance, sustainable materials has positioned Recovered Carbon Black (RCB), derived from the pyrolysis of End-of-Life Tires (ELT), as a critical feedstock. Transitioning this carbonaceous residue into a high-grade industrial filler—often requiring fineness within the 5 to 45 μm range (equivalent to 2500 to 200 mesh )—demands grinding technology defined by unprecedented […]

Using the HGM Ultrafine Grinding Machine to process Chromium Oxide Green (Cr₂O₃) is an efficient way to achieve high fineness, uniform particle size distribution, and stable pigment quality, especially for paint, coating, and ceramic applications. About Chromium Oxide Green Chromium Oxide Green (Cr₂O₃) is an inorganic green pigment widely used in paints, coatings, plastics, ceramics, […]

Calcium oxide is an inorganic compound, usually grayish-white, pale yellow or gray when it contains impurities, and is hygroscopic. Calcium oxide can be ground into calcium oxide powder by CLUM ultra-fine vertical roller mill. Calcium oxide powder is widely used and can be used to make calcium carbide, soda ash, bleaching powder; it can be […]

The calcite powder ground by CLUM vertical mill has a fineness of D97 up to 3000 mesh and a content of 2μm up to 70%. The powder has high whiteness, no impurities…

CLUM ultrafine vertical roller mill can grind coal gangue into pure high-quality micro powder, which is widely used in the construction industry.

Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill. Coal gangue powder is widely used in the construction field.

The HGM series ultra-fine grinding mill produced by SBM can grind perlite into fine powder of about 2500 mesh, which can be used as filler in rubber and plastic products, pigments…

The processing of cristobalite into fine powder needs to go through two main stages of crushing and grinding. The equipment used is jaw crusher and Raymond mill, followed by feeder, elevator, powder separator, dust collector, etc.

The dolomite crushing and sand making production line has the advantages of high degree of automation, high crushing efficiency, low operating cost, energy saving and environmental protection, and fine sand making size.

The process flow of manganese oxide ore mainly includes crushing, grinding and beneficiation. Manganese ore is mainly used in metallurgical industry and chemical industry.