The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

29/08/2022 admin

The dolomite crushing and sand making production line has the advantages of high degree of automation, high crushing efficiency, low operating cost, energy saving and environmental protection, and fine sand making size.

Dolomite has a Mohs hardness of 3-4 and a specific gravity of 2.85-2.9. It is a sedimentary carbonate rock. It is mainly composed of dolomite, often mixed with quartz, feldspar, calcite and clay minerals. It is gray-white, brittle, and has high hardness. It is easy to scratch with iron. In case of dilute hydrochloric acid, it foams slowly or does not foam, and its appearance is very similar to limestone. According to the origin, it can be divided into primary dolomite, diagenetic dolomite and epigenetic dolomite; according to the structure, it can be divided into crystalline dolomite, residual dissimilar particle dolomite, clastic dolomite, microcrystalline dolomite, etc.

Dolomite can be used as refractory inner layer of reformer used in steelmaking, slagging agent, cement raw material, glass flux, kiln industry, fertilizer, stone for construction and decoration, paint, pesticide and medicine. It can be used in building materials, ceramics, glass and refractory materials, chemical industry, agriculture, environmental protection, energy saving and other fields. It is mainly used as a flux for basic refractories and blast furnace ironmaking; for the production of calcium magnesium phosphate fertilizers and for the production of magnesium sulfate; and as ingredients for the production of glass and ceramics.

The processing of dolomite can be divided into four production processes: coarse crushing by jaw crusher, medium and fine crushing by crusher (fine jaw crusher, impact crusher, etc.) and sand shaping by sand making machine:

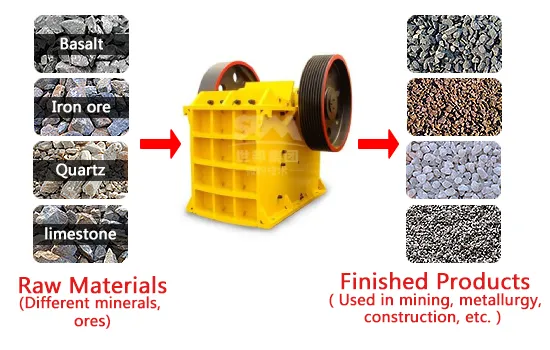

The first stage: Dolomite – coarse crushing

The large pieces of dolomite are transported by special vehicles to the feeder, and then sent to the jaw crusher by the conveyor for coarse crushing and crushed into smaller-sized particles. The jaw crusher has large feeding particle size, large crushing force and crushing ratio, wide application range and many materials.

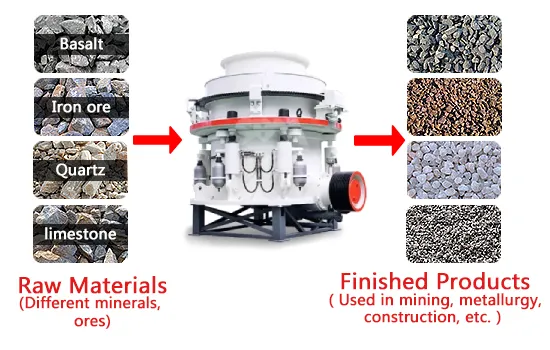

The second stage: Dolomite – medium and fine crushing

The dolomite after being roughly crushed by the jaw crusher enters the secondary crushing for further medium and fine crushing processing, so as to facilitate better sand making in the later stage. Cone crusher has strong processing capacity, and also has the characteristics of automation and intelligence, high production safety and good environmental performance, suitable for crushing hard materials.

The third stage: dolomite – sand shaping

After two crushing processes and screening by the screening machine, the qualified Baiyunshan materials that can be processed for sand making will be crushed into suitable particle size by the sand making machine. The sand making machine can not only be used in the sand making production line, but also in the molding operation of construction waste to improve the quality of sand and gravel. The particle size of the product is cubic, the gradation is reasonable, and the fineness modulus is adjustable. Large output, high efficiency and long maintenance cycle.

The fourth stage: dolomite finished material

After completing the work flow of crushing and sand making, the finished materials of dolomite can be cleaned and dedusted to improve the quality, and then output by the conveyor to the finished material area.

1. High degree of automation

The entire production line requires almost no manual operations except for equipment startup, suspension and routine maintenance. The production line has simple process, high production efficiency, large output and low operating cost. The finished sand and gravel have uniform particle size and good particle shape, which is very in line with the national construction sand standard and high-quality material requirements.

2. Reasonable equipment configuration

In the process flow of the whole dolomite sand production line, the stages of crushing, screening, sand making, sand washing, transportation and other links not only occupy a small area, but also have strict and reasonable space layout, and the economic benefits of sand making are very high. At the same time, it is equipped with an advanced electronic control operating system, which can ensure the smooth discharge of the production line.

3. Granule size can be adjusted

The dolomite sand production line can flexibly adjust the particle size of the finished sand according to the different requirements for the particle size of the finished sand, so as to ensure the timely production of marketable products and reduce the project investment. It not only solves the problem that the quality of sand and gravel particles is not up to standard in the production of traditional sand making equipment, but also overcomes the shortcomings of equipment wear and serious increase in cost due to hard materials.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.