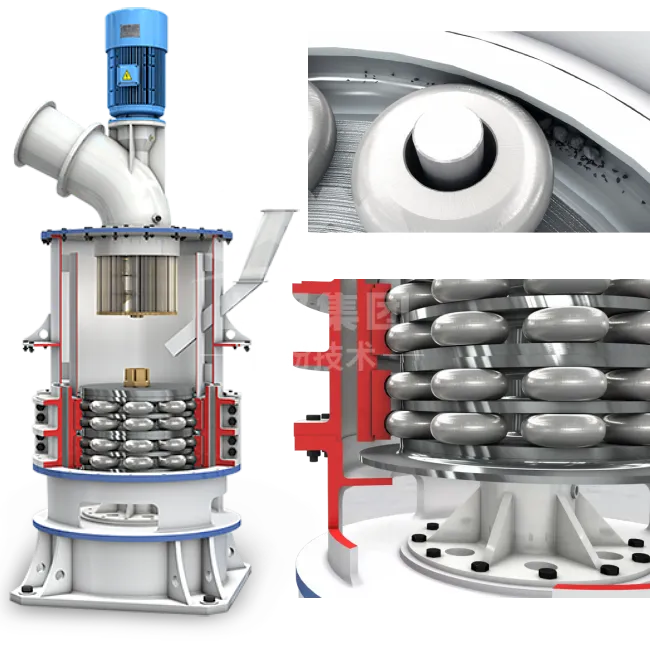

HGM Stone Mill Grinder for Ultrafine Mineral Ore Powder Production

The HGM Stone Mill Grinder, also known as the HGM series ultrafine powder grinder mill,…

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

29/06/2022 admin

Although the industrial ore ultrafine grinding mill produced by our SBM micro-powder technology adopts special synthetic steel material, the wear resistance of the grinding roller and other components of the pulverizer is greatly improved, and the service life of the pulverizer is prolonged. However, their service life is also limited. If they are not paid attention to in daily use, their service life will be shortened, and they will be scrapped in advance. Therefore, in order to prolong the service life of ultrafine grinding, the key is maintenance.

HGM ultrafine grinding mill

Output: 0.2-45t/h

Fineness: 150-3000 mesh

Applicable materials: non-metallic ores, Mohs hardness less than 7, talc, limestone, calcite, calcium carbonate, kaolin, etc.

Advantages: Small footprint, simple computer control operation, long service life of special synthetic steel material, environmental protection and no dust pollution…

1. During the use of the grinding mill, a special person should be responsible for establishing a post responsibility system and operating standards. The operator must be familiar with the performance, usage requirements and operating procedures of the machine. New recruits must undergo technical training and can only operate after meeting the requirements. We at SBM provide operational training to our customers, which is nothing to worry about.

2. The lubrication of the transmission parts in the accessories of the ultrafine grinding mill must be done in place, the addition of lubricants should not be too much or too little, and the selection of lubricants in winter and summer should be correct. And the cleaning of this part must be paid attention to, impurities will contaminate the lubricant and affect its lubricating effect, it is best to regularly and thoroughly clean and add new lubricant according to the work intensity. Our SBM superfine powder mills can be refueled and maintained without stopping, which improves the working efficiency of the mills.

3. Always check the air pressure of the filter bag filter back blowing to avoid blockage of the filter bag, and the decrease of the fan current will affect the output of the equipment. Usually, it is necessary to seal the joints of the pipeline firmly to ensure no air leakage. Check the dust collector regularly. If the filter bag is damaged, it should be replaced in time to avoid pollution caused by dust leakage. The water discharge switch at the lower part of the oil-water separator should discharge water 2-4 times every 8 hours.

4. Check the parts frequently and tighten them in time if they are loose to avoid accidents. If it is found that the wearing parts such as grinding roller, grinding ring, mounting plate and shaft pin are seriously worn, the wearing parts should be replaced at the same time to ensure normal production. The muffler should be cleaned regularly to avoid excessive resistance and affect the air volume of the system.

5. The external working environment of the ultrafine powder mill should be careful to avoid open-air production. Exposure to the sun and rain will cause damage to the mill to varying degrees. If water enters the body, the effect will be even worse. The leaking surface of the mill should also be coated with anti-rust grease. If rust is found, it should be treated immediately, and rust-proof repair measures should be taken.

6. The working hours of the mill should be planned in detail. The machine is the same as the human, so try to avoid overwork. Overworked operation not only has low production efficiency, but also causes huge damage to the machine, and is one of the killers that shorten the service life.

7. The amount of material added in the production process and the humidity of the material should be controlled within an effective range. The material particles and the amount of addition are large or small, and the wearing parts of the grinding roller and grinding ring have a certain degree of wear. Materials with excessive humidity are not easy to grind directly, which will not only cause blockage, but also may corrode internal parts.

The HGM Stone Mill Grinder, also known as the HGM series ultrafine powder grinder mill,…

Discover the HGM ultrafine grinding mill — the ideal Peridotite Stone Industry Grinding Mill Machine…

Choosing the right stone powder grinding mill for your needs is crucial in achieving optimal…

Our HGM and CLUM series ultrafine grinding mills can be widely used to produce high-quality…

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.