The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

24/06/2022 admin

Ball mills and vertical roller mills are common mining machinery that can grind ore into powder and are used in all walks of life. So, what is the difference between a ball mill and a vertical mill? What kind of ore grinding production line is suitable for?

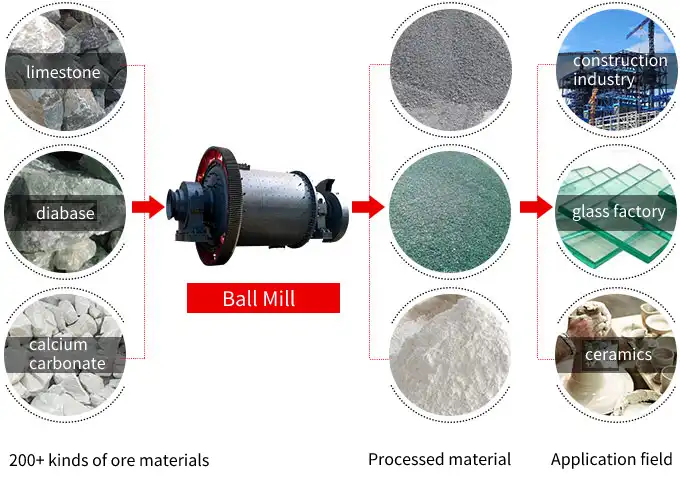

The ball mill is the key equipment for the material to be crushed and then crushed. This type of grinding machine is to put a certain number of steel balls in its barrel as grinding medium.

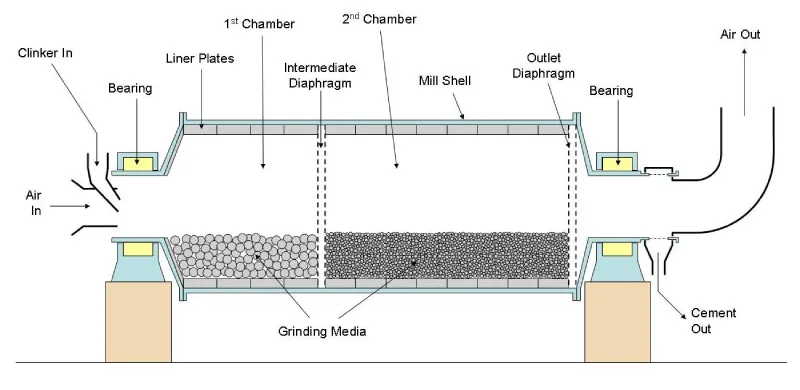

The ball mill is a horizontal cylindrical rotating device, and the material is fed into the first silo of the ball mill by the feeding device through the feeding hollow shaft. There is a stepped liner or corrugated liner in this warehouse, which is filled with steel balls of different specifications. The centrifugal force generated by the rotation of the cylinder will bring the steel ball to a certain height and then fall down, which will have a heavy impact and grinding effect on the material.

After the material is roughly ground in the first silo of the ball mill, it enters the second silo through the single-layer silo partition. The single-layer silo partition is embedded with a flat liner, which contains a ball mill for further grinding of the material. The powder is discharged through the discharge grid of the ball mill to complete the grinding operation.

CLUM vertical roller mill series mainly consists of grinding roller assembly, grinding disc assembly, hydraulic station, transmission arm assembly, powder separator, main reducer, motor, body, main reducer lubrication station, hydraulic station, PLC electrical control cabinet and other parts composition.

When the vertical mill is working, the main motor drives the grinding disc to rotate through the reducer, and at the same time, the hot air enters the vertical grinding mill body from the air inlet, and the material falls into the middle of the grinding disc from the discharge port. Under the action of centrifugal force, the material moves at a uniform speed from the middle of the grinding disc to the edge. When passing through the grinding roller area on the grinding disc, it is crushed by the grinding roller, the bulk material is directly crushed, and the fine-grained material is extruded to form a bed layer for inter-particle crushing.

1. Installation method

The ball mill is installed horizontally, which requires high technical personnel and is difficult to install. Moreover, the requirements for the foundation are also high, the installation period is long, and the floor space is also large.

The vertical grinding mill is installed vertically, with less system equipment, compact structure, small footprint, short cycle, convenient installation and low construction cost.

2. Process flow

CLUM vertical roller mill integrates crushing, grinding, drying and grading, with simple process, compact structure and low operating cost. The ball mill can only pulverize, and other functions need to be configured separately.

3. Processing materials

The vertical roller grinding mill is mainly suitable for superfine powder processing of non-flammable and explosive brittle materials with medium and low hardness and Mohs hardness less than 7.

The ball mill has the unique advantage of “the particle shape is approximately spherical, which is conducive to the calcination of raw meal and the hydration and hardening of cement”, which is the main reason why clinker mills still use ball mills.

4. Grinding process

In the ball mill, the material is mainly crushed by impact and friction. In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary. The residence time of the material in the vertical mill is 2-3 minutes, while in the ball mill it takes 15-20 minutes. Therefore, using the vertical mill to grind the material can avoid the phenomenon of over-grinding, which is beneficial to the homogenization of the product.

5. Grinding process

Vertical grinding is mainly based on grinding and crushing, so it is more suitable for fine grinding and ultra-fine grinding. The whole system consumes fewer grinding media and has a longer service life of the lining. The grinding roller of CLUM vertical roller mill is made of special alloy steel, which is more wear-resistant and has a longer service life.

The ball mill is more suitable for coarse grinding and fine grinding, and adopts the method of impact crushing, so the consumption of grinding media is very large, which makes the life of the mill lining short.

6. Energy consumption

Under the same power condition, the grinding efficiency of the ball mill is low, and the energy consumption is high. The vertical mill has high grinding efficiency and low energy consumption, and the power consumption is only 40%-50% of the ball mill.

7. Finished product quality

Compared with the ball mill, the product of the vertical mill has a higher degree of homogenization and higher purity. This is because when the vertical grinding mill is working, the time used for the classification of the finished powder is short, which avoids over-grinding, while the ball mill is easy to over-grind.

In addition, due to the unique working principle of the vertical mill, there is no direct metal contact with each other during the operation of the vertical grinding mill, the metal wear is small, and the pollution to the finished material is small. Much smaller. Vertical mill grinding is very convenient to adjust the speed of the separator, the wind speed and the pressure of the grinding roller, and the fineness of the product can be adjusted conveniently.

8. Environmentally friendly

The vertical mill adopts full negative pressure operation, with little dust, cleanliness and consumption reduction, and no dust pollution. The ball mill is open, and the dust is large, and the environmental pollution is large.

Comprehensive comparison, the advanced grinding technology of vertical mill can overcome many defects of ball mill. The vertical grinding mill has the advantages of high grinding efficiency, low power consumption, simple grinding process, small footprint, low civil construction cost, low noise, low wear, long life and easy operation. Greatly improve production efficiency, reduce production costs and maintenance costs. For stones with a Mohs hardness of less than 7, vertical roller mills are more suitable for grinding than ball mills.

You can use the following PDF file to understand the detailed comparison between vertical mill and ball mill more intuitively.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.