The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

07/06/2024 admin

Our HGM and CLUM series ultrafine grinding mills can be widely used to produce high-quality ground calcium carbonate(GCC).

Today we will take you to visit one ground calcium carbonate/GCC plant in Sichuan Province, China. See how ground calcium carbonate is produced.

In this tour of the GCC (Ground Calcium Carbonate) Ultrafine Grinding Mill Plant, we will walk through the seven main steps involved in producing ultrafine GCC powder. Each step is crucial to ensure the final product meets the desired quality and specifications.

The process begins with the washing of raw materials. This initial step is essential to remove any dust and impurities from the surface of the raw limestone. Clean raw materials are critical for maintaining the quality of the final product. The washing process typically involves the use of water and mechanical agitation to cleanse the limestone before it undergoes further processing.

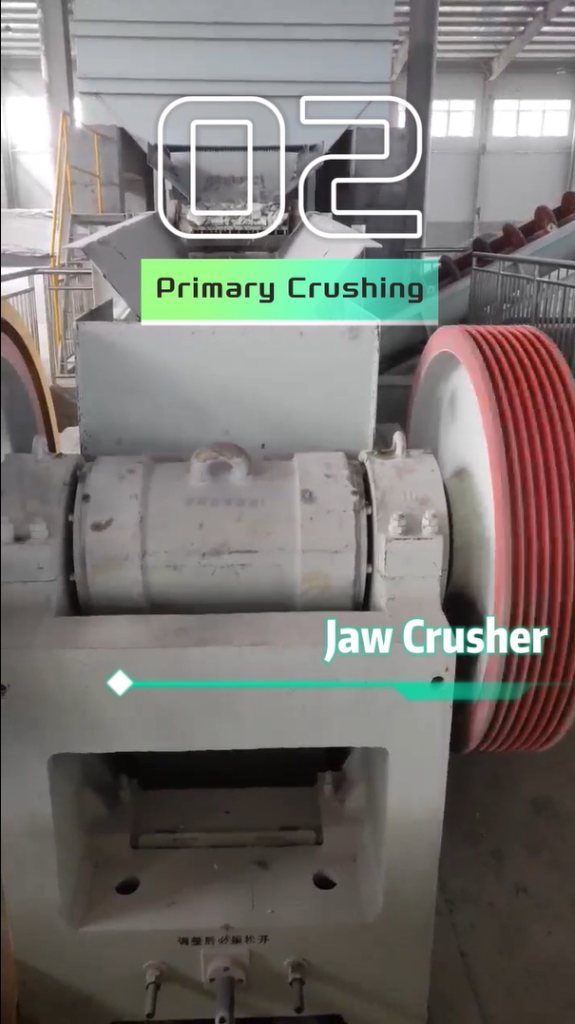

Once the raw materials are washed, they are subjected to primary crushing. In this step, a jaw crusher is used to crush the limestone stones initially. The jaw crusher is designed to reduce the size of large rocks into smaller, manageable pieces. This initial crushing phase prepares the material for more refined crushing and grinding stages, ensuring that the subsequent equipment can handle the material efficiently.

After primary crushing, the crushed material needs to be transported to the next level of processing. Conveying systems, such as belt conveyors, are used to move the material seamlessly between different stages of the plant. Efficient conveying systems are crucial for maintaining a steady flow of material and optimizing the overall productivity of the plant.

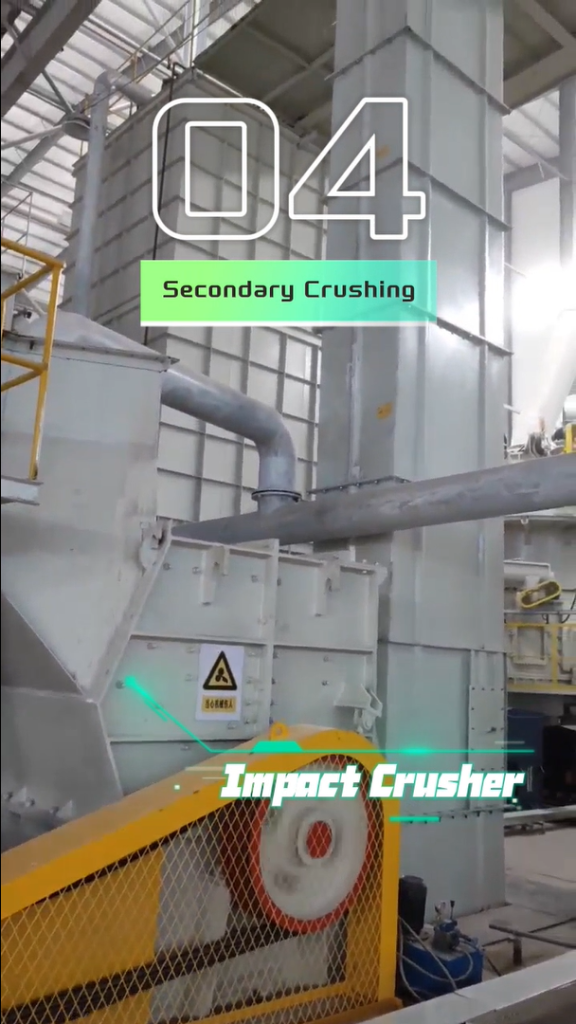

In the secondary crushing stage, the material undergoes further size reduction. An impact crusher is employed to crush the material to less than 20 mm in diameter. This finer crushing prepares the material for the grinding process. The impact crusher’s design ensures that the material is uniformly reduced in size, which is important for the consistency and quality of the final product. Once the material is adequately crushed, it is fed into the grinding mills.

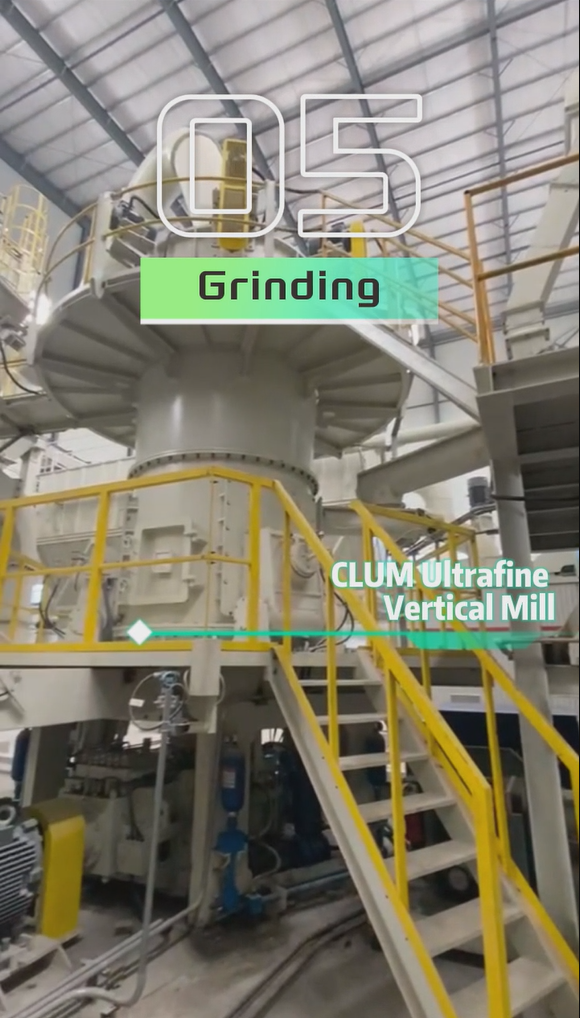

Grinding is a critical step in the production of ultrafine GCC powder. The plant uses advanced grinding equipment, including HGM ultrafine mills and CLUM ultrafine vertical mills. These mills are capable of producing ultrafine powder with particle sizes ranging from 150 to 3000 mesh. The grinding process involves the use of rollers and high-speed rotors to pulverize the material into fine particles. The quality of the grinding process directly impacts the fineness and purity of the GCC powder.

To ensure quality and prevent contamination, the powder conveying stage is fully sealed. Sealed conveying systems are used to transport the finely ground GCC powder to the next stage of processing. This not only prevents dust emissions, which can be harmful to both the environment and workers but also maintains the integrity and purity of the powder.

The final step in the production process is packaging. To make the process more efficient, the plant utilizes fully automatic packaging and stacking machines. These machines are designed to package ultrafine GCC powder into various sizes and types of bags or containers, depending on customer requirements. Automation in packaging ensures precision, reduces labor costs, and enhances the overall efficiency of the plant. Proper packaging also protects the product during transportation and storage, ensuring that it reaches the customer in optimal condition.

The production of ultrafine GCC powder involves a series of carefully controlled steps, from washing and crushing to grinding and packaging. Each stage is designed to ensure the highest quality of the final product, meeting the stringent standards required by various industries that use GCC powder. The use of advanced equipment and automation not only enhances efficiency but also ensures the safety and cleanliness of the production process.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.