The products of Shibang Industry & Technology Group, Shanghai Ultrafine Powder Tech. Co., Ltd. are widely used in various industries of modern industry, such as metallurgy, building materials, chemical industry, mining, papermaking, ceramics, plastics, composite materials, rubber and coatings.

Regularly report real-time dynamic information of domestic and foreign mining and mineral powder industry.

Rhyolite is a silica-rich volcanic rock widely used in construction materials and ceramics.Processing involves crushing → grinding → classification to achieve different applications. Rhyolite is a type of volcanic igneous rock that forms from high-silica (acidic) lava. It is chemically similar to granite, but because it cools quickly on or near the Earth’s surface, its […]

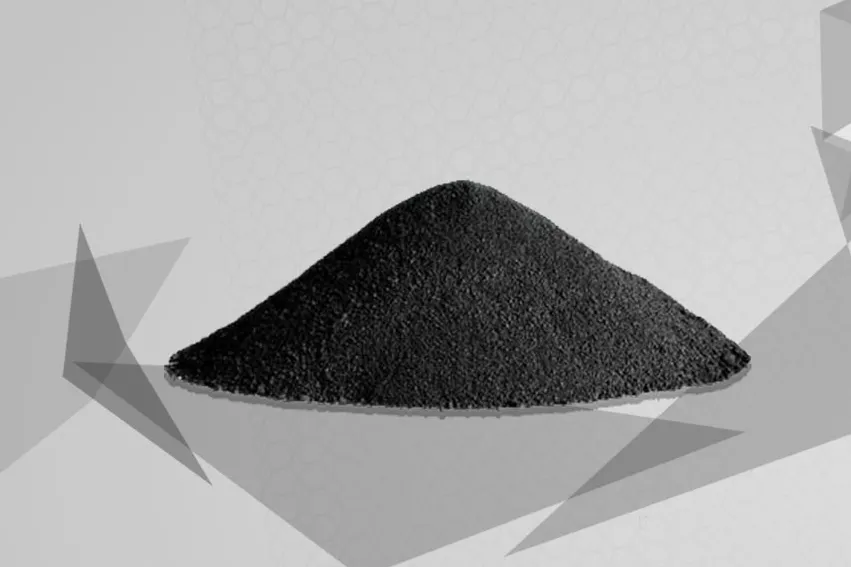

The industrial pursuit of high-performance, sustainable materials has positioned Recovered Carbon Black (RCB), derived from the pyrolysis of End-of-Life Tires (ELT), as a critical feedstock. Transitioning this carbonaceous residue into a high-grade industrial filler—often requiring fineness within the 5 to 45 μm range (equivalent to 2500 to 200 mesh )—demands grinding technology defined by unprecedented […]

Using the HGM Ultrafine Grinding Machine to process Chromium Oxide Green (Cr₂O₃) is an efficient way to achieve high fineness, uniform particle size distribution, and stable pigment quality, especially for paint, coating, and ceramic applications. About Chromium Oxide Green Chromium Oxide Green (Cr₂O₃) is an inorganic green pigment widely used in paints, coatings, plastics, ceramics, […]

Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization.

During the operation of the ultrafine grinding mill, the pulverizer sometimes encounters some work friction and other effects, which will make the equipment in a bad state. So what matters need to be paid attention to in the daily maintenance of the ultrafine mill?

Although in terms of appearance, hammer crusher and impact crusher are somewhat similar, there are major differences between the two in many aspects.

Jaw crusher and impact crusher are the main crushing equipment in ore crushing production line. The jaw crusher is used for coarse crushing of ore, and the counterattack crusher is used for medium and fine crushing of stone.

Limestone is a soft material, widely distributed and easy to mine. The processed stones can be used to configure concrete, mortar, road paving, etc., with a wide range of applications and great market demand. So, how to configure the limestone crushing equipment?

After the granite is crushed and processed by sand making, it can be made into machine-made sand aggregate, which has higher industrial and economic value. What kind of machine is used for granite crushing?

There are many reasons for the decline of jaw crusher output, such as the humidity, hardness and fineness of the crushed material, which are caused by external factors and improper human operation.

Because of its simple structure, convenient maintenance and repair, reliable operation and low production cost, stone crushers are widely used in medium-sized crushing of ore and bulk materials.