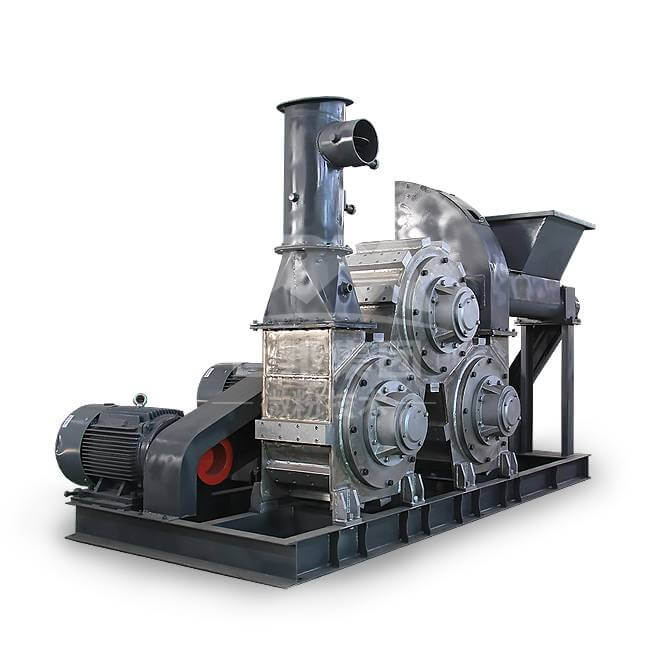

The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

07/06/2022 admin

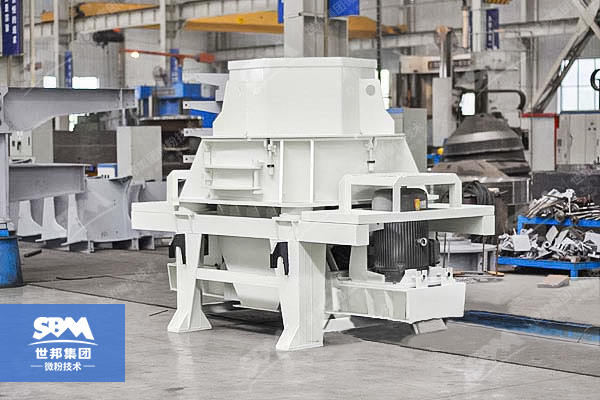

With the development of the sand and gravel aggregate industry and the concrete industry, we have made great progress in the processing technology of mining waste rock crushing. The mine waste rock processing technology designed by SBM micropowder tech can not only effectively remove mud, powder and other problems, but also monitor the material output in real time, effectively control the particle shape and particle size of the finished machine-made sand and gravel aggregate, and ensure that it is more in line with high-grade or even ultra-high grades. The material requirements of high-grade concrete are applied to large-scale construction projects such as highways and railways.

The solid wastes produced by mining and beneficiation are divided into two categories, namely waste rock and tailings.

Waste rock refers to the general term for the ore body surrounding rock and rock inclusions that are produced in the process of mining without industry. For pit mining, it is the rock that is separated out during tunnel excavation and stope blasting and cannot be used as ore. For open pit mines, it is the surrounding rock and rock inclusions on the surface of the ore deposit that have been stripped off. Generally speaking, 6-8 tons of waste rock are stripped for every ton of ore mined in an open pit mine.

Tailings are the wastes discharged by the concentrator after grinding the ore and selecting useful components under specific economic and technical conditions. That is to say, the solid waste remaining after the ore is concentrated elsewhere is the “waste” discharged by mining enterprises under certain technical and economic conditions, but it is also a potential secondary resource.

Mine waste rock, as a secondary mine resource, has the value of further comprehensive development and utilization, whether it is from the needs of social and economic development, or from the needs of protecting resources and sustainable development of mining enterprises. At present, the common uses of mine waste rock are roughly as follows: for the production of sand and gravel aggregates, concrete fine aggregates, the use of waste rock as railway ballast, as the basic raw material for the production of cement, as a cement mixing material, for the production of various Bricks, raw materials for the production of silica bricks, calcium carbonate production, heavy calcium carbonate raw materials, etc.

Most waste rock can be used as coarse and medium-sized aggregates, so the processing of waste rock requires necessary raw material testing to test its physical and mechanical properties to ensure that it is within the scope of the national standards for the use of building raw materials and meets the Requirements for construction materials.

After the raw material testing is completed, the waste rock production process is determined in a targeted manner according to factors such as lithology, mining methods, and physical properties. For example, for waste rock with higher hardness and less soil content (granite, etc.), and for waste rock with lower hardness and more soil content (such as limestone, etc.), the specific processes are quite different.

☏ WhatsApp: +86 18917951321

According to the differences in ore lithology, mining methods, physical properties, soil content, etc., the processes and equipment for producing sand and gravel aggregates from mine waste are also different.

For example, when the hardness of the waste rock is high and the soil content is low, it is recommended to use the cone crusher instead of the impact crusher in the medium and fine crushing stage. Among them, the single-cylinder hydraulic cone crusher is used in the medium crushing stage, and the multi-cylinder hydraulic cone crusher is recommended for the fine crushing stage. In this way, the “lamination crushing principle” of the multi-cylinder hydraulic cone crusher can be used, so that the finished aggregate can obtain a better particle shape.

For more detailed production line equipment configuration solutions, please feel free to contact us.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.