The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

03/01/2024 admin

Volcanic stone is a natural rock formed by volcanic eruptions and has the following properties:

Porous: The porosity of volcanic stone is as high as more than 40%, so it has good water absorption, heat preservation, heat insulation, breathability and other properties.

The density is low, generally 1.0-1.8 g/cm³, so it is light and easy to process.

High strength: The compressive strength of volcanic stone is as high as more than 200Mpa, so it has good wear resistance and impact resistance.

Acid and alkali resistance: Volcanic stone has good acid and alkali resistance, so it can be used in acid and alkali environments.

No pollution: volcanic stone is a natural mineral, non-polluting and non-radioactive.

Volcanic rocks can be crushed and ground through crushers, mills and other equipment. Volcanic stone powder has the following uses:

Agriculture: Can be used as fertilizer, soil conditioner, thermal insulation material, etc.

Construction: Can be used as thermal insulation materials, fireproof materials, sound-absorbing materials, etc.

Industry: Can be used as abrasives, fillers, adsorbents, etc.

Medical treatment: can be used as biological materials, drug carriers, etc.

Specifically, the applications of volcanic stone powder in the field of building materials mainly include:

Lightweight concrete: Volcanic stone powder can replace part of the cement to produce lightweight, heat-insulating and heat-insulating concrete.

Thermal insulation materials: Volcanic stone powder can be used to produce thermal insulation boards, insulation mortars and other thermal insulation materials.

Sound-absorbing materials: Volcanic stone powder can be used to produce sound-absorbing panels, sound-absorbing paint and other sound-absorbing materials.

In the agricultural field, volcanic stone powder can be used as:

Fertilizer: Volcanic stone powder is rich in minerals and can be used as fertilizer to promote plant growth.

Soil conditioner: volcanic stone powder can improve soil structure and increase soil fertility.

Adsorbent: volcanic stone powder can absorb heavy metals and harmful substances in the soil and purify the soil.

In the industrial field, volcanic stone powder can be used as:

Coating: Volcanic stone powder can improve the thermal insulation, heat insulation and anti-corrosion properties of the coating.

Rubber: Volcanic stone powder can improve the strength, wear resistance and heat resistance of rubber.

Plastics: Volcanic stone powder can improve the strength, heat resistance, and corrosion resistance of plastics.

In the field of medicine, volcanic stone powder can be used as:

Drugs: Volcanic stone powder can be used as a carrier for drugs to improve the absorption rate of drugs.

Cosmetics: Volcanic stone powder can be used as a raw material for cosmetics and has moisturizing, whitening, anti-aging and other effects.

1. Raw material preparation

Quarry: Volcanic rock comes from quarries or mines.

Crushing: Breaking large rocks into smaller pieces using a jaw crusher, cone crusher or hammer mill.

Cleaning: To remove impurities such as dust and dirt, the gravel is washed with water.

Magnetic Separation: If iron impurities are present, they are removed using magnetic separation technology.

Grading: The cleaned and pre-treated volcanic rocks are further graded through vibrating screens to obtain different desired particle sizes.

2. Grinding

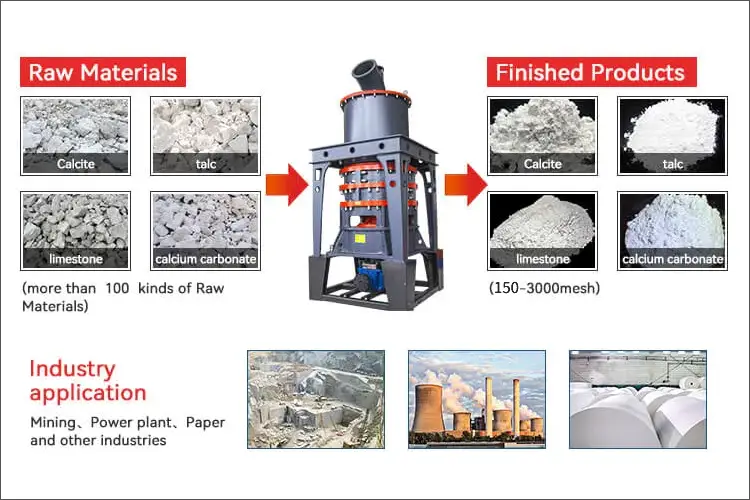

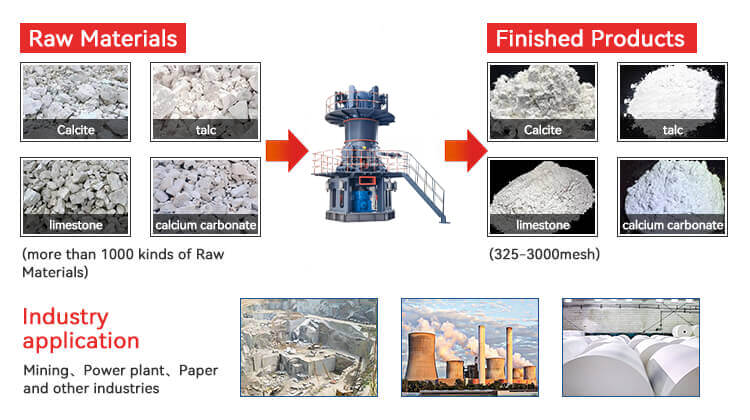

Choose a grinding mill based on required fineness and production capacity:

Ultra-fine grinding mill: can produce volcanic stone powder with a fineness of 200-2500 mesh.

Roller mill: can produce medium to fine powder with high productivity.

Vertical grinding mill: It can produce volcanic stone powder with a fineness of 300-3000 mesh. The finished product has high purity and high powder quality.

Hammer mill: Great for achieving coarse to medium fineness, but may produce more dust.

3. Classification and separation

Sieving: Vibrating screens or air classifiers further separate the ground powder into different particle size fractions according to the required specifications.

Magnetic separation (optional): If any iron-containing impurities have not been removed previously, magnets can be used to separate them at this stage.

4. Packaging

Bagging: Classified finely ground volcanic stone powder is packed into various sizes and types of bags depending on the final product and customer requirements.

Bulk Loading: For large-scale applications, powders can be loaded directly into bulk containers or tankers.

5. Quality control

Throughout the entire process, quality control is crucial. Samples of raw materials, crushed stone, ground powders and final products are regularly tested for physical and chemical properties to ensure they meet the required specifications.

Other notes:

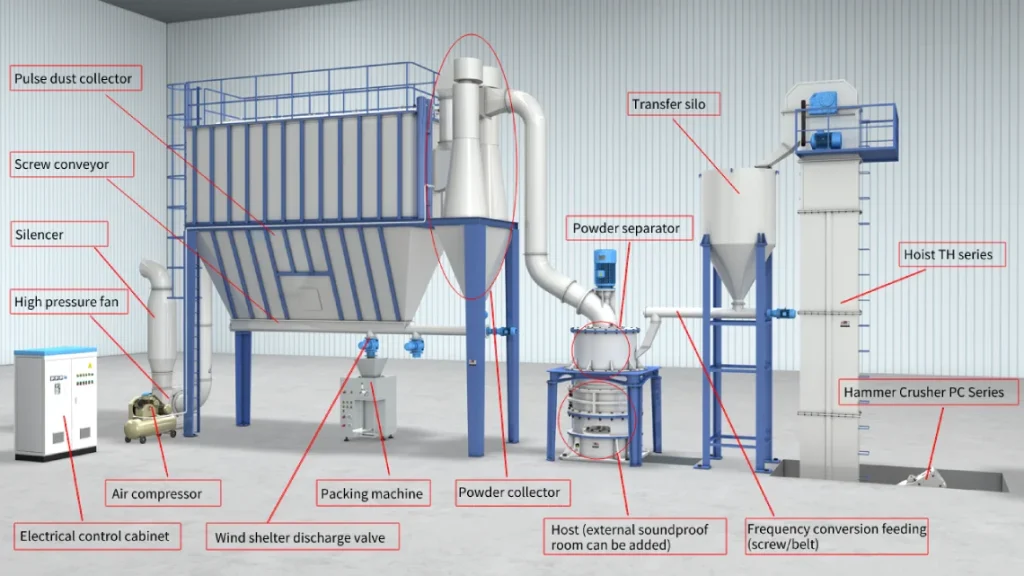

Dust Control: Grinding generates dust, so proper dust collection and ventilation systems are critical to maintaining a safe and healthy work environment.

Waste Management: Crushed rock and oversized particles can be recycled or used in other applications to minimize waste.

Environmental impact: Production processes should be designed to minimize environmental impact, such as reducing water consumption and dust emissions.

By following this process flow and considering these additional factors, a volcanic stone grinding production line can effectively produce high-quality volcanic stone powder suitable for a variety of applications.

High production efficiency: The volcanic stone grinding production line adopts advanced equipment and technology, has high production efficiency and can meet the production needs of different scales.

Stable product quality: The volcanic stone grinding production line adopts scientific control methods to ensure stable and reliable product quality.

Environmental protection and energy saving: The volcanic stone grinding production line adopts advanced environmental protection equipment, which can reduce pollution and save energy.

The main equipment of the volcanic stone grinding production line includes

Crusher: The volcanic stone crusher is the first step in the volcanic stone grinding production line. It is mainly used to crush the volcanic stone raw materials into a certain particle size. Commonly used volcanic stone crushers include jaw crushers, impact crushers, cone crushers, etc.

Screening machine: The volcanic stone screening machine is the second process of the volcanic stone grinding production line. It is mainly used to classify the crushed volcanic stone according to particle size. Commonly used volcanic stone screening machines include vibrating screens, drum screens, etc.

Pulverizer: The volcanic stone mill is the core equipment of the volcanic stone grinding production line. It is mainly used to finely grind the screened volcanic stone to obtain the required powder particle size. Commonly used volcanic stone mills include vertical mills, ultra-fine mills, roller mills, etc.

Classifier: The volcanic stone classifier is the third process of the volcanic stone grinding production line. It is mainly used to classify the ground volcanic stone again to ensure the uniformity of the powder particle size. Commonly used volcanic stone classifiers include vibrating screens, trommel screens, etc.

Packaging machine: The volcanic stone packaging machine is the last process of the volcanic stone grinding production line. It is mainly used to package the classified volcanic stone for transportation and sales. Commonly used volcanic stone packaging machines include ton bag packaging machines, bulk packaging machines, etc.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.