The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

24/02/2023 admin

Sodium saltpeter (Na[NO3]), also known as Chilean saltpeter, is a symbiotic mineral with a hardness between 1.5 and 2. The symbiotic minerals include gypsum, thenardite, and rock salt. There are two colors of white and colorless, and some impurities may appear as light gray, light yellow or brown. Sodium nitrate can be used to make nitrogen fertilizer, nitric acid and other professional fertilizers, compound fertilizers, or other nitrogen compounds after being ground.

The particle size of sodium saltpeter depends on the specific application scenarios and requirements, and different industries and products have different requirements for the particle size of sodium saltpeter. Under normal circumstances, the sodium saltpeter used in industry generally needs to be ground to a fineness of about 200 mesh to 325 mesh, while the sodium saltpeter used as a fertilizer in agriculture requires grinding to finer particles.

Chemical industry: Sodium saltpeter is an important raw material for the manufacture of nitric acid and nitroglycerin, and is also widely used in explosives, dyes, paints, medicines and other industries.

Agriculture: Sodium saltpeter is a high-quality nitrogen fertilizer, which is widely used in the growth and development of crops to improve yield and quality.

Food industry: As a food additive, sodium saltpeter is used for curing meat products, which has the functions of antisepsis and anti-oxidation.

Other fields: Sodium saltpeter can also be used in the manufacture of glass, ceramics and other products.

The processing of soda saltpetre mined in bulk generally requires crushing, grinding and screening, which specifically includes the following steps:

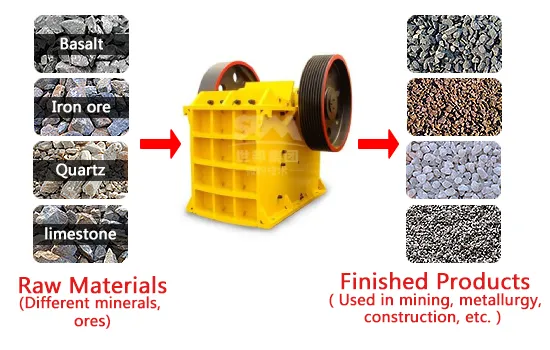

Crushing: Crushing large pieces of sodium saltpeter through crushing equipment, usually jaw crushers, cone crushers and other equipment.

Grinding: The crushed sodium saltpeter particles are still relatively large and need to be further ground by grinding equipment to refine the particles. Commonly used grinding equipment includes ball mills, vertical mills, and Raymond mills.

Sieving: The milled sodium saltpeter powder needs to be sieved to remove impurities and coarse particles and improve the purity and quality of the product. Screening is usually performed using equipment such as sieves or vibrating screens.

Packaging: Sodium saltpeter products after the above treatment can be packaged for storage and transportation.

It should be noted that different application fields of sodium saltpeter have different requirements for its particle size, purity and other indicators, and the processing process will also vary accordingly. At the same time, safety and environmental protection should be paid attention to during processing to avoid harm to the environment and human body.

The milling process of the ultra-fine mill production line of SBM micro-powder technology is under closed negative pressure, and there is no problem of dust overflowing and polluting the environment, which is very in line with the safety requirements of sodium saltpeter processing. Sodium saltpeter grinding powder production line features:

1. Reasonable configuration, reduced land occupation, cost saving, and safe work.

2. On-site environmental protection, low-carbon work, in line with green milling operations.

3. High work efficiency, large output, automatic operation, on-site operation can be controlled by computer.

4. The output is uniform, the finished powder has high purity and less impurities, and the quality after post-processing is higher.

The crushing and grinding production line of sodium saltpeter usually includes multiple equipments, the following are some common equipments:

Jaw Crusher: It is used for primary crushing of larger pieces of sodium saltpeter and crushing them into particles of appropriate size. The jaw crusher has the advantages of simple structure, high output, few breakdowns and small investment.

Impact Crusher: It is used to finely crush and crush the sodium saltpeter crushed by the jaw crusher.

Vibrating screening machine: used to screen and classify the crushed sodium saltpeter and enter the qualified particles into the next process.

Milling machine: used to grind larger sodium saltpeter particles into finer powder to meet specific production needs.

Discharge fineness: 325-2500 meshes

Feed size: <25 mm

Output: 0.5-45 t/h

Discharge fineness: 150-3000 mesh

Feed size: <20 mm

Output: 1-20 T/H

Discharge fineness: 80-600 mesh

Feed size: <35 mm

Output: 0.4-35 t/h

Discharge fineness: 0.075-0.4 mm

Feed size: <25 mm

Output: 1-200 T/H

Powder Separator: The ground sodium saltpetre powder is further refined and sieved to obtain finer particles.

Packing machine: Automatically pack the processed sodium saltpeter products to facilitate storage and transportation.

The above equipments are just some common ones, and the specific crushing and milling production line configuration and equipment quantity will vary according to production requirements and product specifications.

In addition, there are some auxiliary equipment and supporting facilities that are also indispensable in the crushing and grinding production line, such as:

Conveyor: It is used to transport raw materials, crushed particles and powders, etc. to various processes and equipment to realize automated production processes.

Dust collector: used to collect dust and exhaust gas generated during the production process to ensure the hygiene and safety of the working environment.

Cooling equipment: used to reduce the temperature of machinery and equipment, prevent overheating and damage, and also help to maintain the quality and performance of sodium saltpeter.

Control system: used to automatically control the operation and parameters of each equipment in the production line to achieve precise production management and control.

It should be noted that different manufacturers and production line configurations may have slight differences, but the core equipment and supporting facilities of the entire crushing and grinding production line are generally similar.

It should be noted that sodium saltpeter is a toxic substance, and safety and environmental protection should be paid attention to in the process of processing and use, so as to avoid harm to the human body and the environment. During the processing of sodium saltpeter, the following matters need attention:

Storage and transportation: Sodium saltpeter is a deliquescent substance. During storage and transportation, it is necessary to pay attention to moisture-proof, sun-proof, and shock-proof measures to avoid affecting product quality.

Cleaning equipment: In the process of crushing and grinding, the equipment will generate dust and dirt, and it is necessary to clean the equipment regularly to keep the production environment clean and avoid affecting product quality.

Temperature control: During the processing of sodium saltpeter, care should be taken to control the temperature to avoid adverse effects on the product due to excessively high or low temperature.

Adding additives: During the processing of sodium saltpeter, some additives, such as anti-caking agents and moisture-proofing agents, are sometimes added to improve the physical properties and performance of the product.

In general, the processing of sodium saltpeter needs to be carried out according to a certain process flow to ensure the quality and purity of the product. At the same time, it is necessary to pay attention to safety and environmental protection during processing, and to abide by relevant operating procedures and standards to avoid harm to the human body and the environment.

SBM micro-powder technology specializes in the production of mining ore crushing and grinding industrial equipment. Our products cover coarse crushing, medium crushing, fine crushing, coarse grinding, fine grinding, ultra-fine grinding and other fields. Especially our ultra-fine grinding mill sells well in the global market and is favored by many customers. We have a professional technical team that can provide you with a complete set of production line configuration solutions; we have professional operators who can provide you with equipment operation training; we have a professional after-sales team that can provide you with comprehensive after-sales services. You are welcome to contact us at any time, we will become your reliable partner!

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.