The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

11/03/2022 admin

A stone crusher is a solid material crusher. Equipment that uses mechanical energy to break ore, concrete or other building materials into small pieces.

Stone crushers are widely used in mining, smelting, building materials, roads, railways, water conservancy and other departments. The stone crusher can crush hard and medium hard ores and rocks, such as iron ore, limestone, quartz, granite, cement clinker, etc. It is mainly used for coarse crushing, medium crushing and fine crushing of various materials whose compressive strength does not exceed 320 MPa.

Crushing machinery includes jaw crusher (coarse crushing, medium crushing, fine crushing), impact crusher, hammer crusher, combined crushing and screening equipment, compound crusher, vibrating screen series, roller crusher, impact crusher etc.

Granite, Marble, Basalt, Limestone, Quartz Stone, River Pebble, Iron Ore Copper Ore…

Introduction

The jaw crusher is mainly used for medium and coarse crushing of various materials whose compressive strength does not exceed 320 MPa.

It has the characteristics of large crushing ratio, high output, uniform product size, simple structure, reliable operation, easy maintenance, and economical operating costs.

Widely used in mining, smelting, building materials, roads, railways, water conservancy and other departments.

Working principle

The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft.

When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate to approach the fixed jaw plate, and at the same time, the material is crushed or chopped to achieve the purpose of crushing.

When the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the crushed materials are discharged from the lower opening of the crushing cavity.

With the continuous rotation of the motor, the crushing jaws perform periodic motions to crush and discharge materials to achieve mass production.

All kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.)

Introduction

The impact crusher can handle all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with side length not exceeding 500 mm and compressive strength not exceeding 350MPa.

Widely used in hydropower, highway, artificial sand and gravel, crushing and other industries.

Features

① Unique structure, keyless connection, high chrome plate hammer, unique counterattack liner.

② Hard rock crushing, high efficiency and energy saving.

③ The shape of the product is a cube, the size of the discharge is adjustable, and the crushing process is simplified. It is an ideal processing equipment for aggregates used in advanced highway surfaces and hydropower construction.

Working principle

When the impact crusher is working, driven by the motor, the rotor rotates at a high speed. After the material enters the crushing cavity, it is crushed by the high-speed impact of the plate hammer on the rotor. The crushed materials are thrown to the counterattack plate at the other end of the crushing chamber at high speed along the tangential direction, and are crushed again. Then it bounces from the impact plate to the blow bar, and the process continues to repeat.

On the way back and forth, the materials also collide with each other. As the material is hit by the plate hammer, the impact with the counterattack plate and the collision between the materials, the material is constantly cracked, loose and crushed. When the particle size of the material is smaller than the gap between the impact plate and the blow bar, it is discharged.

Can crush coal, salt, chalk, gypsum, brick, limestone, etc.

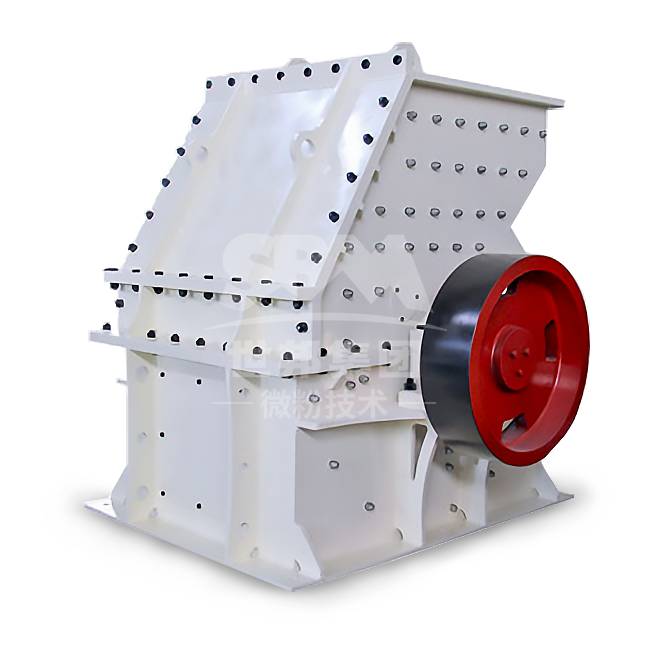

Introduction

Hammer crusher is a kind of equipment for crushing materials in the form of impact, which can directly crush materials with a maximum particle size of 600-1800 mm to below 25 or 25 mm.

Hammer crusher is suitable for medium and fine crushing in cement, chemical, electric power, metallurgy and other industries, and can crush medium-hard materials, such as limestone, slag, coke, coal and other materials.

Features

(1) The working hammer head is cast by new technology, which is wear-resistant and impact-resistant.

⑵ According to customer requirements, adjust the required granularity.

(3) The structure of the hammer crusher is sealed, which solves the problem of dust pollution and ash leakage in the crushing workshop.

⑷ The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.

⑸ Compact structure, beautiful appearance, good wear resistance and easy maintenance.

Working Principle

Hammer crushers mainly rely on impact energy to complete the operation of crushing materials. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, the material enters the crusher cavity evenly, and the high-speed rotating hammer impacts, shears and tears the material, causing the material to be broken.

At the same time, the gravity of the material itself causes the material to rush from the high-speed rotating hammer to the baffle plate and sieve bar in the frame, and the material larger than the size of the sieve hole stays on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required size. The discharge particle size is finally discharged out of the machine through the sieve plate.

Suitable for fine crushing and ultra-fine crushing of hard rocks, ores, slag, refractory materials, etc.

Introduction

Cone crusher is a crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical and silicate industries. Widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries and many other industries.

The cone crusher has large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. It is suitable for medium and fine crushing of various ores and rocks.

Features

● Higher production capacity, better quality.

● Due to the safety device, the downtime is greatly reduced.

● The body is a cast steel structure, and there are reinforcing ribs in the heavy-duty parts.

● With adjuster, it can quickly adjust the size of crushing and discharging granularity.

● Provide spring protection device.

● With a complete lubrication system, it will automatically shut down when the temperature is too high or the flow rate is too slow.

● The internal structure has good sealing performance, which can effectively protect the equipment from dust and other small particles.

● Long service life and strong applicability.

Working Principle

During the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric sleeve. The static cone is broken by multiple squeezing and impact.

When the moving cone leaves this section, the material that has been crushed to the required particle size falls under its own gravity and is discharged from the bottom of the cone.

1. The type and hardness of the material

The type and hardness of the material are the first factors to be considered when choosing crushing equipment. Different types of materials will have different hardness and structure, which has the primary limitation on the choice of stone crusher. Generally, the greater the hardness, the higher the crushing difficulty coefficient.

2. Material Specifications

If the particle size of the material is large, the jaw crusher can be selected for coarse crushing. When the particle size of the stone is small, and it is composed of a certain amount of stone, the combined crushing and screening equipment should be used.

3. Moisture of the material

The moisture content of the material will also affect the choice of the crusher. When the water content is too large, due to the increase of humidity, the fine material will agglomerate or stick to the coarse material, thereby increasing the viscosity of the material, reducing the discharge speed and reducing the productivity. In severe cases, it will even block the discharge port, affecting normal production.

4. Granularity requirements

The incoming and outgoing particle size is used to judge the type and crushing grade of the required crushing equipment.

5. Output requirements

The output requirement is an important indicator to determine the crushing equipment. The higher the output requirements, the larger the size of the crushing equipment required, and the corresponding input and output will also increase.

6. Construction site

The specific situation of the construction site is the most direct factor affecting the selection of crusher equipment, such as the size of the construction site and the specific placement of the crushing equipment.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.